What Should Be Paid Attention To When Using Electromagnetic Overband Separator?

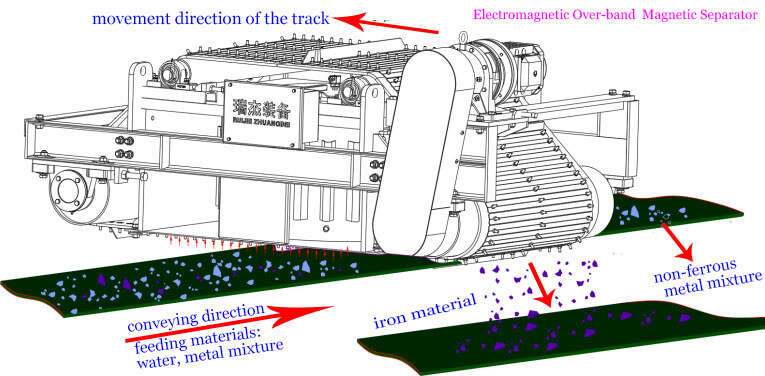

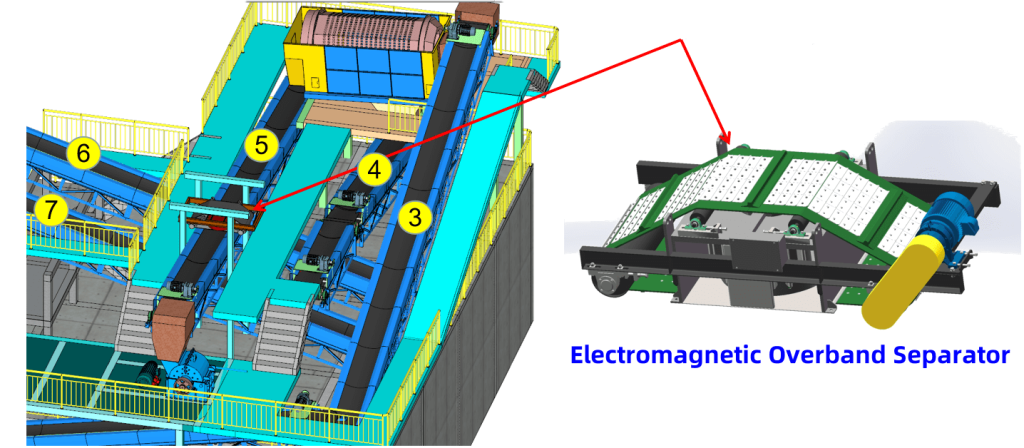

The electromagnetic overband separator relies on the electromagnetic magnetic group to adsorb the iron on the surface of the track, and the track moves to the left to convey the iron to the side of the conveyor belt and falls into the iron conveyor belt.

The roller rotates about 96 revolutions per minute, and before the test is carried out, carefully observe whether there is any foreign matter stuck between the roller and the belt. When starting, carefully observe for abnormal noises.

During the test run, pay attention to whether the motor is running in the correct direction and whether the temperature of each bearing is too high (40°C higher than the normal temperature). Because it is a strong magnetic equipment, it is not allowed to carry metal objects within 50cm of the roller regardless of stopping or starting.

The operation of the electromagnetic overband separator equipment is controlled and monitored by the electrical cabinet, please operate according to the identification of the electrical cabinet. If there is an abnormality in the equipment, please press the red emergency stop button on the outer door of the electrical cabinet immediately to avoid unnecessary losses. Before the equipment is in operation, it is forbidden to place other items on any part of the equipment.

Conclusion

In today’s industrial production, the suspended permanent magnet iron remover or electromagnetic overband separator, as a key equipment, is widely used in material conveying systems to effectively remove ferrous impurities and ensure the smooth operation of the production line.