People focus entirely on sustainability now because recycling serves as a critical practice for waste administration and resource preservation and environmental impact minimization. The recycling industry depends heavily on the fundamental process which separates metals from all other types of nonmetallic materials.

The step allows materials to be properly sorted before their processing for subsequent use in manufacturing and construction together with miscellaneous sectors. The recycling industry’s methods to differentiate metals from nonmetals explains to us the procedures that establish waste cycle management while supporting circular economic practices.

This article discusses the metal separation system in detail and its significance alongside RUIJIE’s advanced metal separation technology.

The Basics of Separation: Why It Matters

Understanding the importance of metal-nonmetal separation methods requires a basic understanding before moving onto technical approaches. Various waste mixtures including industrial waste and post-consumer products and construction debris contain metals which are intertwined with plastics ceramics and wood along with other materials that are nonmetallic. Efficient separation is necessary to:

- Metals of value including aluminium and steel also copper can be extracted from the mix

- The separation of recyclable materials should increase their purity level.

- Reduce contamination in material recovery

- Operation of waste management aims to minimize everything that goes into landfills.

- The economic worth of recovered materials experiences improvement due to better economic value

Inappropriate material separation degrades the recycling process at three levels: it becomes both inefficient and expensive and environmentally damaging.

How Recycling Industry Separates Metals from Nonmetals

Recycling industry implements mechanical along with magnetic and sensor-based systems for detecting metals from nonmetals. Various effective as well as commonly used methods exist for recycling purposes.

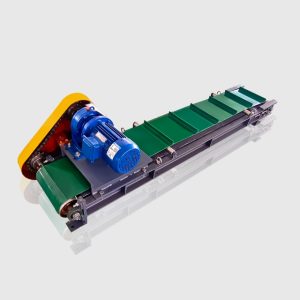

1. Magnetic Separation

The sector extensively employs this technique to isolate ferrous metals while steel represents its primary application. The magnetic force between magnets and ferrous metals enables efficient removal of metal items from waste streams. Mounting forces of magnets on the conveyor system extract metal materials as they move while allowing unexcited nonmetallic elements to stay intact.

Non-ferrous metals such as aluminium or copper along with brass are not affected by magnetic separation since they do not respond to magnets. The recouping procedures for such metals need alternative processing approaches.

2. Eddy Current Separation

Eddy current separators constitute the main technology used by the recycling industry when they need to separate non-ferrous metals from non-metallic materials. Magnetic separators use magnetic fields to create electric currents in non-ferrous metallic items. The influence applies a force that moves ferrous metals away from all other waste materials.

Eddy current separators function exceptionally well to extract aluminium from packaging combined with copper from wiring alongside high-value non-ferrous metals from mixed materials. These recyclers depend on the fast accurate method to process industrial and post-consumer waste.

3. Air Classification and Density Separation

The recycling industry makes use of density separation as a technique for material sorting that depends on both weight and size considerations. Air classification systems serve as a typical method for this sorting technique. The air currents blow away lighter materials consisting of plastics and paper through different channels before heavier metals descend into another section.

The sorting method proves useful for materials that cannot be separated with magnetic or visual methods because they exist in a shredded or fine state. The combination of gravity alongside airflow performs as an effective process to separate metallic from nonmetallic bulk waste particles.

4. Sensor-Based Sorting

Sensor-based sorting technology has revolutionized recycling operations at its highest level. The sorting systems rely on near-infrared (NIR), X-ray transmission (XRT) and visual recognition sensors to detect materials by their chemical compositions which enables proper sorting.

The sensors measure the composition details or mass density and reflective patterns to establish item classification results as metal or nonmetal. The automated arms or air jets operate according to sensors to guide materials into their proper channels. Such technology enables high levels of accuracy to work efficiently on complicated waste materials from factories that need precise handling.

5. Manual Sorting and Pre-Sorting

At present several facilities continue to rely on manual sorting operations as the initial defense system alongside their technological resources. Workers start by removing too-large objects or dangerous items along with manually categorizing particular waste items until equipment-based technology begins operation. By sorting waste in this manner facilities create better conditions for their separation processes through both machine protection and intact waste quality.

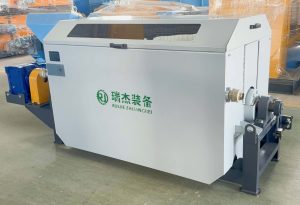

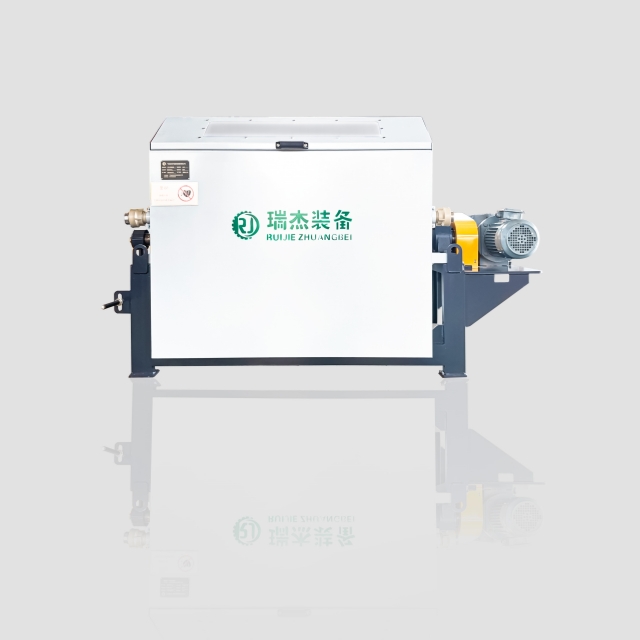

RUIJIE’s Role in Modern Metal Separation

RUIJIE stands as the leading company developing industrial high-efficiency metal sorting and separation equipment for industrial applications. The machines from RUIJIE specialize in managing difficult waste streams that comprise slag together with Auto Shredder Residue (ASR) and Incinerator Bottom Ash (IBA) and additional industrial scraps.

RUIJIE builds equipment that operates differently from residential waste systems because its machinery addresses high-stress industrial metal extraction needs. RUIJIE implements high-performing eddy current separation and sensor-based sorters and air classification technology to accurately extract metals from large-volume nonmetallic waste streams.

Why This Process Matters for the Future

The technological separation of metals from nonmetals serves as both a technical operation and a fundamental process to handle worldwide waste management and environmental protection. The escalating demand for raw materials together with diminishing landfill availability has made recycling emerge as a strategic yet environmentally friendly solution. RUIJIE’s efficient separation systems through their offerings enable

- We should use previously discarded valuable materials rather than extract new items from the earth

- Lowering pollution through greenhouse gas emission control during metal production activities

- Minimize pollution and environmental degradation

- The establishment of a circular economy system that is sustainable represents our main objective

The proper financing of recycling infrastructure combined with advanced technologies enables substantial advances in industrial materials recovery and reuse methods.

Conclusion

We gain better understanding about the complex nature of modern recycling operations through studying how the industry separates metals from nonmetals. Various technological systems which combine magnetic separators with eddy current separators as well as sensor-based systems and air classification help recover valuable metals while minimizing waste generation.

The industrial waste transformation receives leadership from RUIJIE through its advanced equipment installations which resolve difficult challenges. Their technological devices combine efficiency with accuracy in order to drive sustainable metal recycling practices.

The development of a sustainable future depends on efficient metal separation methods which serve as fundamental units of responsible waste management. Innovation together with determination will let the recycling industry recover more waste while decreasing landfill waste as it builds a sustainable planet for upcoming generations.