What is the Gravity Sorting Process of a Jig Machine Like?

Jig machine is a commonly used mineral gravity sorting equipment, which mainly uses water flow and gravity to sort between valuable minerals and gangue minerals.

Jig concentrators are widely used for the separation of metallic minerals, including lead, zinc, tin, copper, iron, manganese, and chromium, among others. Due to the large density difference between metallic minerals and gangue, jigs are able to effectively separate valuable metallic minerals from gangue. The following will focus on the aspect of the process flow, and the jig reseparation process will be introduced.

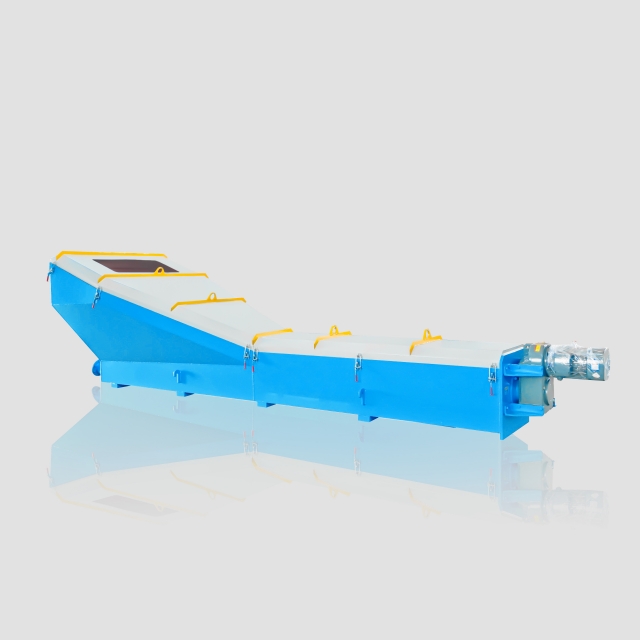

RUIJIE Sawtooth Wave Jig Resorting Process

1.Ore Crushing and Grinding: The Sawtooth Wave Jig gravity separation process begins in the crushing and grinding stages of the ore. The raw ore is fed into the crusher to be crushed into smaller particles and further refined by the grinding equipment for better physical separation.

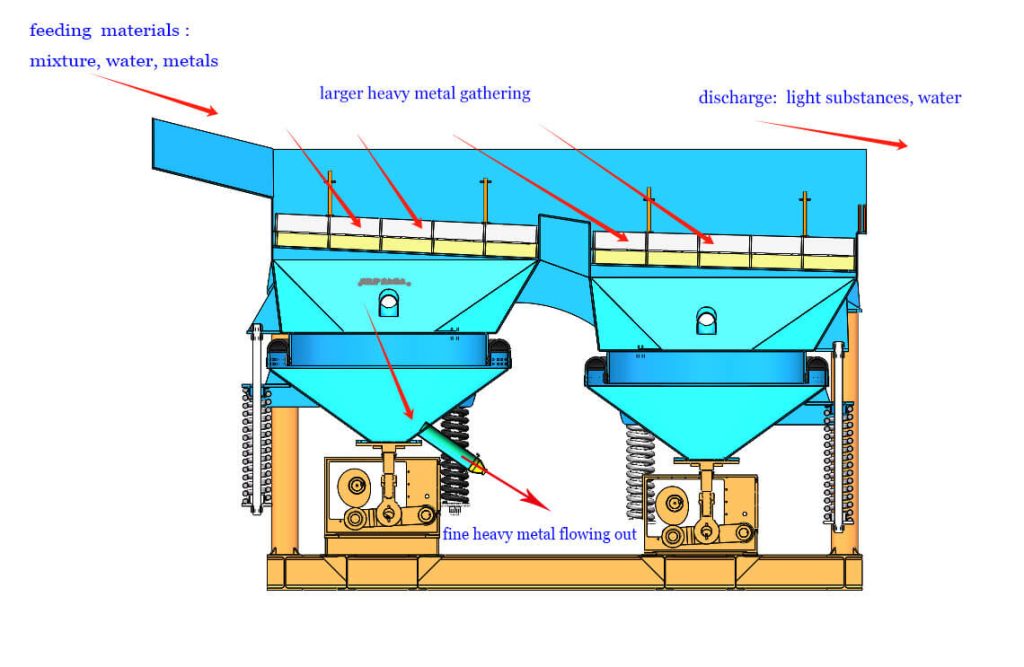

2.Primary Gravity Separation: First, the ore is fed into the primary jig concentrator through a vibrating feeder. Primary jig concentrator use water flow and gravity to separate valuable minerals and gangue material from the ore. Since minerals of different densities sink at different speeds, valuable minerals are concentrated at the bottom of the Saw Tooth Wave Jig, forming a coarse concentrate.

3.Intermediate Gravity Separation: Coarse concentrates often require further processing to improve the grade of valuable minerals. They are fed into intermediate gravity separation equipment, such as spiral chutes or heavy media beneficiation equipment. These units perform further separation based on the density difference between the valuable minerals and gangue, producing a higher grade concentrate.

4.Fine-grained Gravity Separation: After intermediate gravity separation, the concentrate may still contain impurities. To further improve the grade of valuable minerals, the concentrate is fed into a refinement gravity separation facility, such as a shaker or centrifuge. These devices separate at a higher level of fineness, concentrating valuable minerals into purer concentrates.

5.Collecting and Handling Concentrates: Finally, concentrates collected from the gravity separation process often need to go through subsequent processing steps, such as drying, smelting, or leaching, to extract valuable minerals. At the same time, tailings may still contain small amounts of valuable minerals, so proper treatment is also required to maximize recovery of valuable minerals.

The effectiveness of the jig machine reseparation process depends on the nature of the ore, the choice of reseparation equipment and the adjustment of operating parameters. This method is commonly used for the beneficiation of metallic minerals such as lead, zinc, copper, iron, etc., to improve the grade and recovery of the ore.

Conclusion

The above is the process of gravity separation of sawtooth wave jigger. From the above, it can be seen that there are many influencing factors in the sorting process, and the ore is analyzed, and the appropriate gravity separation equipment and process flow can be selected according to the test results. This can not only improve the sorting efficiency of the equipment, but also improve resource recovery and economic benefits.