What Is The Difference Between Shaftless Trommel Screen And Shafted Trommel Screen?

The screening of sand and gravel aggregates is very common in stone production lines, which are classified according to the shape and size of the material. Our common screening equipment includes trommel screens, vibrating screens, etc.

Trommel screens are divided into shaftless trommel screens and shafted trommel screens, and vibrating screens are divided into linear vibrating screens, circular vibrating screens, swinging screens, self-centering vibrating screens, etc.

Today, Addams will focus on what is the difference between shaftless trommel screen and shafted trommel screen.

Shafted Trommel Screen Machines and Shaftless Trommel Screen Machines

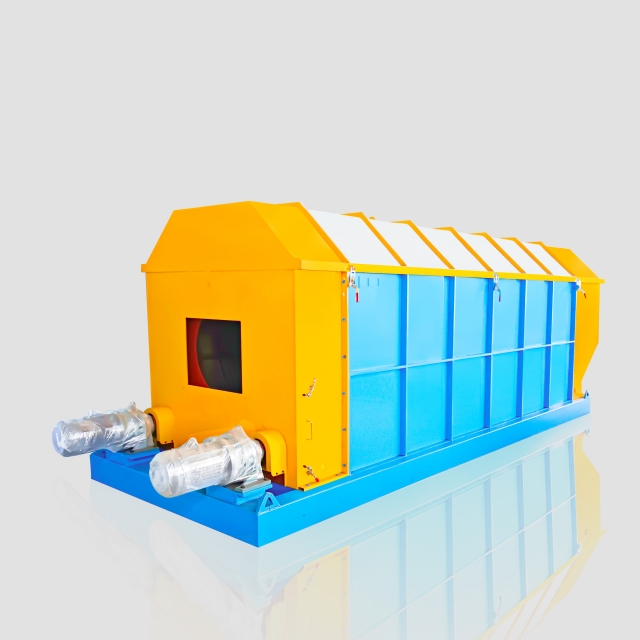

RUIJIE Shafted Trommel Drum Screen

Conventional trommel screens are divided into two types: shaftless trommel screen and shafted trommel screen machine. The shafted drum sieve is connected with the outer drum through a central spindle plus a support frame, and moves in the same direction through multi-point support.

The heavy duty trommel screen is evenly distributed through multi-point support, the sieve body is relatively firm, the overall operation is stable, and the force is uniform. The motor is connected to the central shaft with the reducer to work.

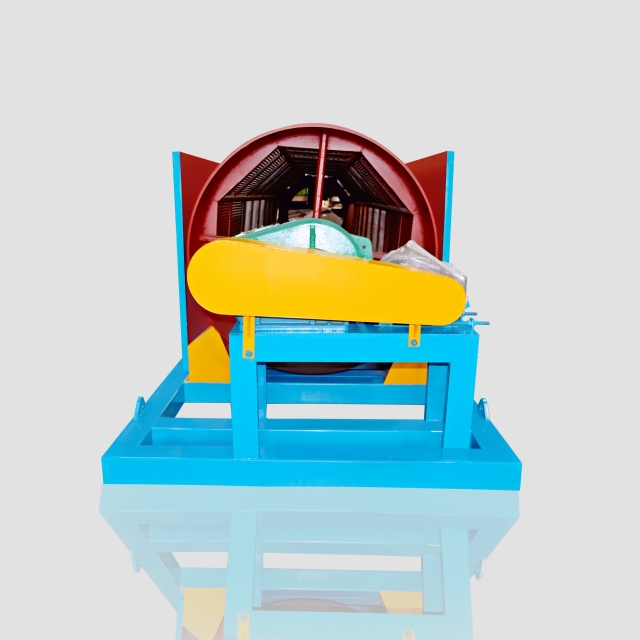

RUIJIE Shaftless Heavy Duty Trommel Screen

The shaftless trommel screen machine relies on the supporting roller to run, the length of the cylinder is 1.5 meters – 7 meters, 4 supporting rollers are used, and 6 supporting rollers are used for more than 8 meters, the weight of the equipment itself increases, and the number of supporting rollers also needs to be increased, and a maximum of 12 supporting rollers can be used.

The shaftless trommel screen drives the supporting roller to rotate in one direction through the motor, and drives the drum to rotate through friction.

The Bearing Force Of The Shaftless Rotary Trommel Screen is Different From The Bearing Force Of The Shafted Screen Machine Trommel

There is a difference between the bearing force of the shaftless trommel screen and shafted trommel screen machine. The bearing capacity of the shafted trommel screen is mainly on the bearings at the front and rear ends of the central shaft, and the force of the drum feed is distributed on the support point of the central shaft.

The support points of the shaftless trommel screen are at both ends, the bearing capacity is distributed on the supporting rollers, and several supporting rollers run in the same direction at the same time to generate friction transmission kinetic energy, so the shaftless trommel has high requirements for the quality of the supporting rollers.

The relative output and screened materials of shafted trommel screens are inferior to those of shaftless trommels. The design of the central shaft of the shafted trommel screen has a limit on the size of the material, and it is inevitable that there will be bags and other easily wound materials when screening construction waste and domestic garbage, and the central shaft will be wound, which will affect the screening efficiency.

There is no obstacle inside the shaftless trommel screen body, the material can be better flipped freely through the screen body, and the cleaning pipeline can also be added, which can reasonably and effectively improve the effect of material cleaning, further improve the screening efficiency, and get rid of the phenomenon that the screen is blocked and the screen is not passable when the vibrating screen and linear screen with large humidity are screened, which increases the reliability and capacity of the overall screening system, and has been recognized by many people.

Shaftless Trommel Screens and Shafted Rollers Screen Other Materials Differently

The shafted trommel screen is mainly used for the input separation of large and small materials in stone plants, sand and gravel plants and mineral processing industries.

The shaftless trommel screen is mainly for the grading of ribbon-shaped and winding materials, which is used for the classification of refractory materials, coal, fertilizer, sand field stones, as well as the screening of viscous wet materials such as coal, coke, white ash, gold ore, etc., so as to make the product structure more uniform to meet the production needs.

Conclusion

Which is better, shaftless trommel screen or shafted trommel screen? You can make the right choice according to your own needs, and the right one is the best, but at present, the mainstream is still shaftless trommel screen, which has more advantages in terms of durability, production capacity, and maintenance management.

RUJIE ZHUANGBEI is a large-scale trommel screen manufacturer, which supports customization of trommel screens with different processing capacity and different usage scenarios.