What are the advantages of optimizing the belt for Ruijie’s eddy current separator?

On the vast stage of resource recycling, Ruijie’s eddy current separator has always occupied the forefront of the industry with their excellent performance and continuous technological innovation. Recently, this equipment has once again brought revolutionary changes to the field of resource recycling through belt optimization and upgrade, starting a new journey of high efficiency, environmental protection, and multi-function.

Efficiency leaps and value co-creation

The optimized belt has injected powerful power into the Ruijie’s eddy current separator, significantly improving the sorting efficiency. The operation of the belt is more stable and smooth, capable of accurately conveying various materials, ensuring that every item to be sorted can enter the sorting process in the best state. Whether it’s a mixture of different materials such as scrap metal, plastic, glass, or recycled materials of various shapes and sizes, it can be easily handled.

This improvement not only significantly shortens the sorting cycle and enhances processing capacity, but also ensures the high quality of recycled materials, thereby increasing the reuse rate of resources, creating more considerable economic benefits for enterprises, and contributing greater value to society.

Durable upgrade, cost reduction

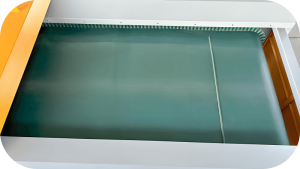

The outer layer of the belt of Ruijie’s eddy current separator is made of PU material, which has good wear resistance, good magnetic permeability, and will not harden due to long-term use; There has also been a qualitative leap in durability, with higher strength and wear resistance, able to withstand long-term high-intensity work without being easily damaged, and able to maintain good condition in harsh environments, effectively reducing the frequency of belt replacement and lowering maintenance costs. This change not only enhances the reliability and stability of the equipment, but also ensures the continuity of production, further improving operational efficiency and laying a solid foundation for the sustainable development of the enterprise.

Has good corrosion resistance

When dealing with various types of materials, it is common to encounter highly corrosive substances. The inner layer of the belt used in our eddy current sorting machine is woven with polyester fiber, which has strong toughness and can effectively resist corrosion, extending its service life and ensuring the long-term stable operation of the sorting machine.

Precise transmission, accurate sorting

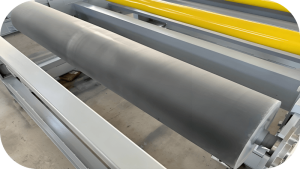

The design and manufacturing of the belt strictly follow high-precision standards to ensure accurate transmission of power during operation, allowing materials to move smoothly on the sorting machine. And this precise transmission performance is attributed to the belt head roller and pulley.

- The outer periphery of the head roller is wrapped in polyurethane, with a curved design of thick middle and thin ends. When rotating, the middle top generates friction with the belt, which can automatically correct the position of the belt and prevent deviation.

- Both ends of the belt are equipped with upper and lower pulleys to ensure the direction of the belt’s movement.

- By adjusting the tension of the belt, ensure that the tension on both sides of the belt is uniform during operation, and avoid deviation caused by uneven tension.

This precise transmission performance helps improve the accuracy and efficiency of sorting, reducing material loss and inaccurate sorting caused by transmission errors.

Leak proof reinforcement, safe and efficient

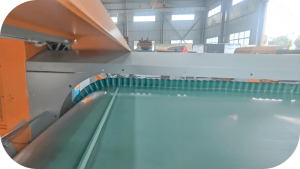

The Ruijie’s eddy current separator adopts a belt with the most suitable width and length, effectively preventing material leakage. Its width and length are perfectly matched with the sorting machine, ensuring that it can tightly adhere to various parts of the equipment during operation, effectively preventing materials from slipping off the edges. The surface of the belt is usually treated with special textures to increase the friction between the material and prevent slippage during transportation, thereby ensuring the safety and efficiency of the sorting process.

Environmental protection, energy conservation, and green development

The Ruijie’s eddy current separator adopts optimized belts and also has significant environmental and energy-saving benefits. Smooth operation reduces noise and vibration, and lowers the impact on the environment. Meanwhile, the efficient sorting process improves resource recovery rate, reduces resource waste, and contributes to environmental protection.

In terms of energy consumption, the optimized belt enables the equipment to use energy more reasonably during operation, reducing energy consumption costs and complying with the concept of sustainable development. This is highly consistent with the sustainable development concept advocated by the society, and has established a good environmental image for resource recycling enterprises.

Wide adaptability and application expansion

The use of optimized belts enables the Ruijie eddy current sorting machine to have stronger adaptability and meet the diverse needs of different customers. Whether it is urban waste treatment, industrial waste recycling, or electronic waste sorting, the Ruijie eddy current sorting machine can play a huge role.

Conclusion

The Ruijie’s eddy current separator has achieved significant results in improving sorting efficiency, enhancing durability, improving sorting accuracy, environmental protection and energy conservation, and adapting to diverse needs through belt optimization. This innovation not only injects new vitality into the resource recycling industry, but also makes important contributions to achieving efficient recycling and sustainable utilization of resources. Looking ahead to the future, Ruijie eddy current sorting machine will continue to lead the industry’s development and create a new chapter in resource recycling.