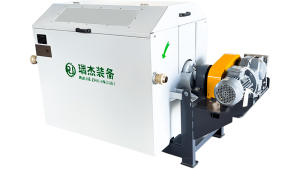

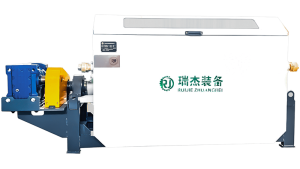

Wet Drum Magnetic Separator: A New Breakthrough in Technological Optimization and Excellent Quality

Wet Drum Magnetic Separator has always played an indispensable role in the fields of mining,Incineration bottom ash(IBA) and renewable resource recovery and treatment. Now, the carefully optimized Wet Drum Magnetic Separator has made a stunning debut, bringing unprecedented efficiency and durability to the industry with its excellent material selection and advanced design.

The optimization highlights of Wet Drum Magnetic Separator are first reflected in the material aspect.

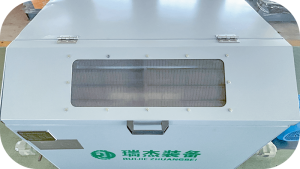

The top cover and body are both made of 201 stainless steel material, and this choice is not accidental. 201 stainless steel is known for its excellent anti-corrosion and rust prevention properties, and can operate stably for a long time in harsh environments such as humidity, acidity, and alkalinity.

♦ The thickness of the top cover is 2 mm, which ensures sufficient structural strength and reasonable weight control, contributing to the overall stability and ease of operation of the equipment.

♦ The thickness of the body reaches 3.5 mm, providing a sturdy and reliable “fortress” for internal precision components, protecting them from external environmental interference and erosion, greatly extending the service life of the equipment and reducing long-term usage costs.

As one of the important components of Wet Drum Magnetic Separator, the performance of the spray pipe directly affects the sorting effect and equipment operation stability.

The PPR hot melt rubber hose has a thickness of 5 millimeters and excellent anti-corrosion and anti explosion performance.

♦ PPR material itself is resistant to chemical corrosion and can effectively resist the erosion of various chemical agents and minerals during the mineral processing, ensuring that the pipeline remains unobstructed for a long time.

♦ Its excellent anti explosion characteristics provide higher safety guarantees for equipment operation. Even under high-pressure water flow impact or large temperature changes, it can always remain intact and provide stable water source support for the magnetic separation process, ensuring the continuity and accuracy of the separation operation.

In terms of the power core of the equipment – the operating motor, we have chosen well-known domestic brand motors. It provides strong motor power, smooth operation, and low noise for Wet Drum Magnetic Separator, which can easily meet the load requirements under various complex working conditions. Efficient energy conversion efficiency not only helps to reduce energy consumption, but also reduces heat generation during equipment operation, further enhancing the overall stability and reliability of the equipment.

The optimized Wet Drum Magnetic Separator has demonstrated significant advantages in practical applications.

♦ In the iron ore selection operation, its stable magnetic field strength and precise sorting effect effectively improve the grade and recovery rate of iron concentrate. Compared to traditional magnetic separation equipment, the processing capacity and durability of the new equipment have been significantly improved, greatly enhancing production efficiency and bringing more substantial economic benefits to the enterprise.

♦ In the field of non-ferrous metal ore sorting, such as the processing of copper, zinc and other ores, its precise magnetic separation performance can effectively remove iron impurities, improve concentrate quality, and meet the strict requirements of high-end markets for non-ferrous metal purity.

From an environmental perspective, the optimization of this Wet Drum Magnetic Separator also has positive significance.

Efficient sorting and durability reduce resource waste, improve the utilization rate of mineral resources, and conform to the concept of sustainable development. At the same time, the application of its anti-corrosion and anti rust materials and stable operating characteristics have reduced waste emissions and energy consumption during equipment maintenance, providing strong support for green production in mining enterprises.

Conclusion

Looking ahead to the future, we will continue to uphold the spirit of innovation and continuously explore the optimization and upgrading path of Wet Drum Magnetic Separator technology. Continuously monitor the development trends of new materials and technologies, and further enhance the performance and intelligence level of equipment. Strengthen communication and cooperation with users, gain a deeper understanding of actual production needs, and tailor more personalized and efficient magnetic separation solutions for different industries.

At the same time, actively expanding the international market and promoting this high-quality wet magnetic separator product globally, contributing to the development of the global mining, Incineration bottom ash(IBA) industry, and renewable resource recycling and processing industry. We believe that with our unremitting efforts, Wet Drum Magnetic Separator will shine brighter on the future industrial stage, helping the industry move towards a more brilliant tomorrow.