Waste Glass Impurity Removal and

Sorting Solution

Professional Waste Glass Impurity Removal Equipment Manufacturer

We are a Waste Glass Impurity Removal Equipment manufacturing direct factory, and we provide recycling solutions and machines to more than 20 glass bottle recycling factories across the country to recycle metal and finely sort waste glass.

Ruijie focuses on the cullet recycling industry, is committed to the development and application of optical sorting systems, and is a leading supplier of optical sorting technology in China.

The new generation of domestic cullet glass optical sorter developed by RUIJIEZHUANGBEI can calmly cope with various complex working conditions, with extremely high sorting efficiency and excellent reliability. At the same time, Ruijie’s professional technical team can provide customers with complete cullet sorting processes such as dry, semi-dry, and wet.

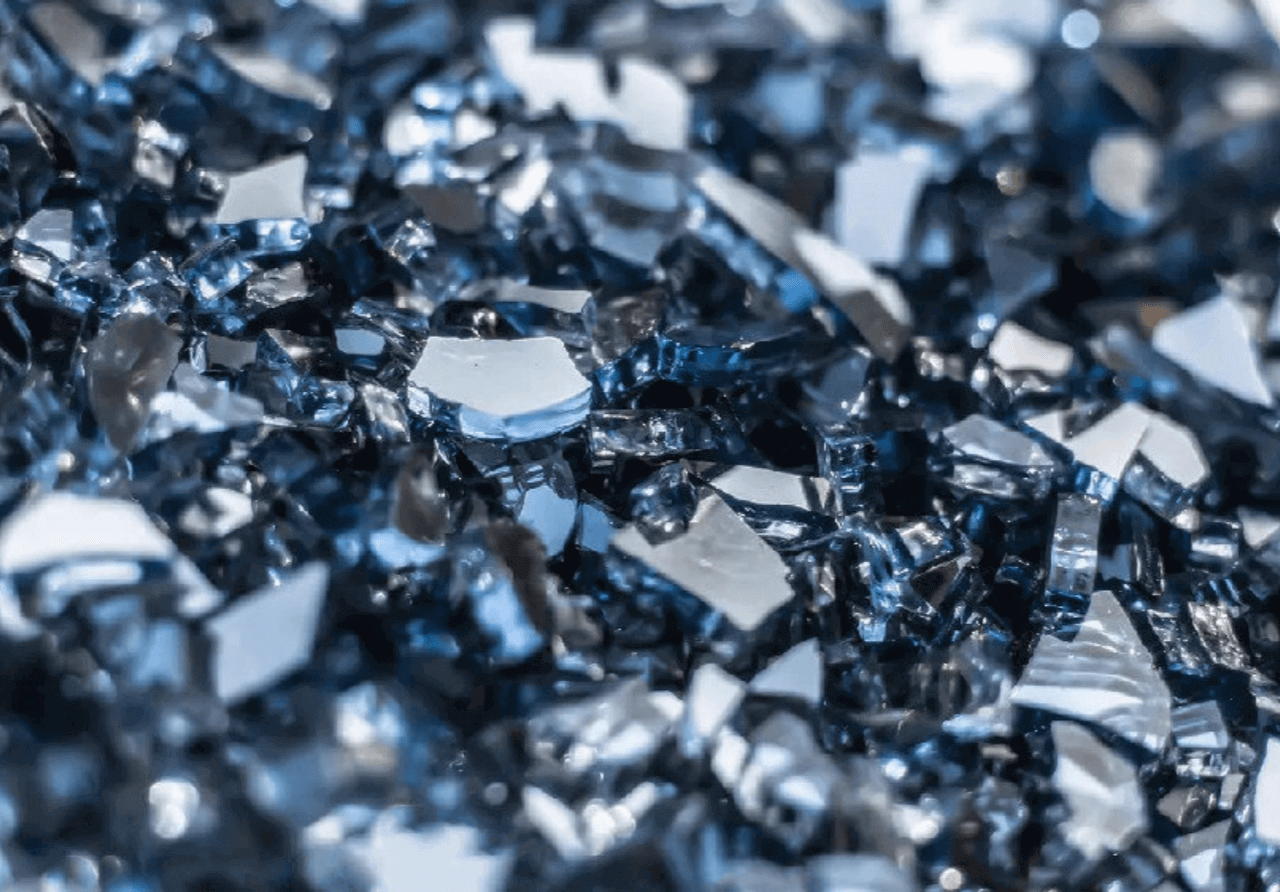

Waste Glass Needs to be Properly Sorted and Recycled

Glass has appeared in human history for more than 4,000 years, and today, glass can be seen everywhere from high-rise buildings to bottles and cans, but with it comes a large amount of waste glass.If waste glass is not recycled, it is not conducive to waste reduction. The cost of collection, transportation and incineration is very high, and it cannot be naturally degraded after landfilling, and even some waste glass contains heavy metals such as zinc and copper, which will pollute the soil and groundwater if discarded at will.

According to statistics, the use of recycled glass can save 10%~30% of coal and electricity, reduce air pollution by 20%, and reduce the exhaust gas generated by mining by 80%. Recycling one ton of waste glass can save 720 kilograms of quartz sand, 10 tons of coal, and 400 degrees of electricity.

Most of the recyclable glass comes from waste glass bottles, waste flat glass, etc. Different types of glass products differ in composition and production processes, so they need to be accurately sorted during the recycling process. Proper sorting not only helps to increase recycling efficiency, but also reduces costs and energy consumption in the subsequent treatment process.

What Are The Types Of Recyclable Glass?

01.Bottle Glass

Bottle glass is the most common type of recyclable glass. It is usually used to package various beverages, spices, food, etc., such as bottled water, beer bottles, beverage bottles, spice bottles, etc.

These kind of glass products have the characteristics of hardness, heat resistance, corrosion resistance, and easy cleaning. After washing, the glass can be used again.

02.Flat Glass

Flat glass refers to clear or colored glass sheets that are flat-mounted or bent. It can be used in construction, furniture, flower stands, vehicles, and other fields.This kind of glass products has the characteristics of high transparency, ultraviolet resistance, heat resistance, fire resistance, etc. After recycling, flat glass can be remade into a variety of glass products.

When it comes to recycling glass products, cleaning is an important step in ensuring the quality of the recycled glass. Removing residues and stains prevents contamination of the entire recycling process and ensures that the recycled glass can be reused to make new glass products.

RUIJIE Automatic Sorting Equipment

The use of RUIJIE automatic sorting equipment can realize the automatic sorting of iron, aluminum and plastics, and improve the pass rate of finished products; At the same time, it can reduce the number of production personnel and reduce wage costs.

For the automatic sorting and separation technology of waste glass impurities, it is necessary to use the highly intelligent automatic production equipment produced by our company.

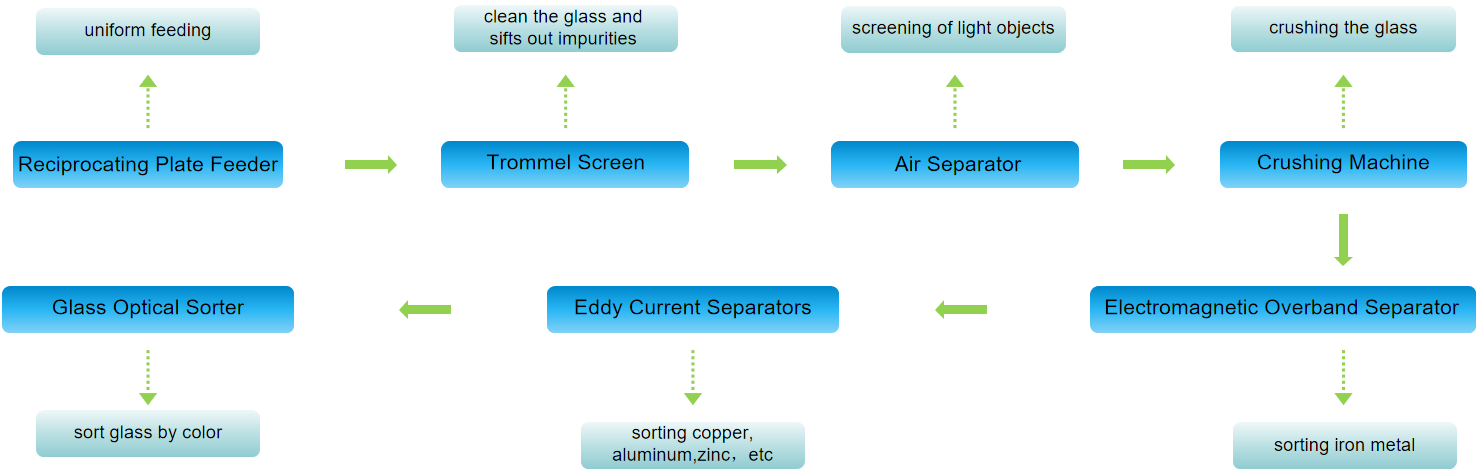

Waste Glass Recycling and Impurity Removal Process

1.The chain feeder provides uniform feeding for the entire process sorting line.

2.The trommel screen cleans the glass and sifts out impurities.

3.The winnowing machine removes light impurities such as lint, particles, and debris from the glass mixture.

4.The crushing machine will crush the material through the crusher to facilitate the work below.

5.Iron removal is carried out by Electromagnetic Overband Separator

6.The eddy current separator equipment is then used to separate the valuable non-ferrous metals.

7.Finally, through the color sorter, the single-color glass is purified to improve the recycling quality and price of waste glass.

Waste Glass Sorting Process Flow Chart

Whether it’s eddy current separators, magnetic separators or Glass Sorting Machine, we are able to design and manufacture them precisely and in a tailor-made way to the needs of glass bottle recycling companies.

RUIJIE eddy current separator can remove loose non-ferrous metal particles (for example:aluminum caps and aluminum rings in used beverage bottles).

Magnetic separators can separate the residue of iron, such as metal rings and hoops (from the neck of the neck). Our Stainless Steel Sorting Machine can even be used to extract stainless steel springs (which can also be extracted from the neck of the bottle)

If you need technical assistance, expert advice, mechanical equipment, as well as more information about the waste glass processing and recycling system, Please feel free to contact us.