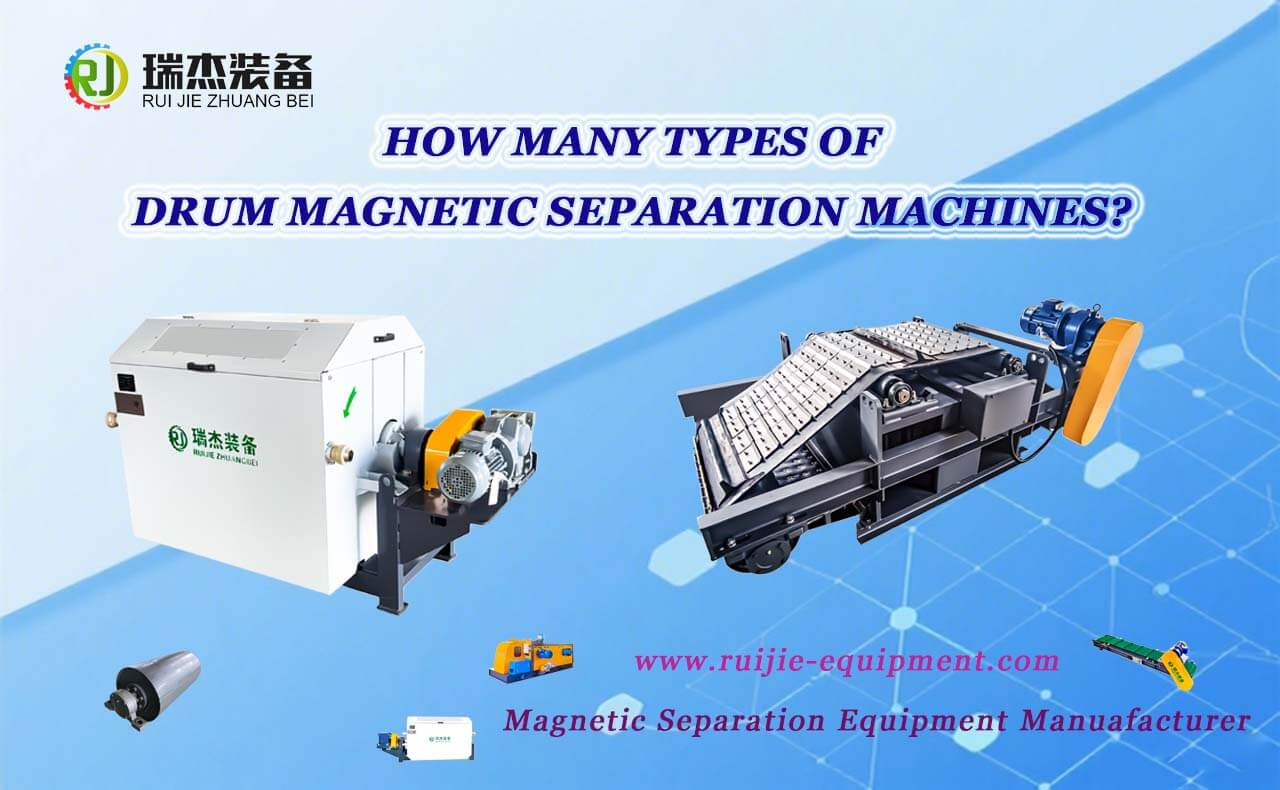

The Difference Between Dry And Wet Magnetic Separator

What Is The Difference Between Dry Magnetic Separator And Wet Magnetic Separator?The main difference between a dry magnetic separator and a wet magnetic separator is their working environment, applicable objects, process flow, and application fields.

1.Working Environment and Applicable Objects:

The Dry Magnetic Separator is used for separation in air, mainly used for separating large-grained, coarse-grained strong magnetic ore and fine-grained weak magnetic ore.

It requires the sorted minerals to be dry, and the particles can move freely and form an independent free state, which is suitable for the wet magnetic separation of magnetite, pyrrhotite, roasted ore, ilmenite and other materials with a particle size of less than 3mm, and is also used for iron removal operations of coal, non-metallic ores, building materials and other materials

The Wet Magnetic Separator must rely on water as the medium in the beneficiation process, which is suitable for the separation of fine-grained strong magnetic ore and fine-grained weak magnetic ore.

It is also used for wet magnetic separation of magnetite, pyrrhotite, roasted ore, ilmenite and other materials with a particle size of less than 3mm, as well as iron removal operations of coal, non-metallic ores, building materials and other materials.

2.Magnetic Separator Process Flow:

The dry magnetic separation plant can realize the separation of minerals without water, and the process flow is simple. It is suitable for ores with a humidity of less than 5%.

The process of a wet magnetic separator is relatively complex because it relies on water as a medium to improve the separation efficiency

3.Magnetic Drum Separators Application Field:

The Dry Magnetic Sorting Machine is very suitable for arid and water-scarce areas, saving water resources, reducing the cost of mineral processing, and opening up a new way for the mining and utilization of ultra-poor magnetiteIt is widely used for the re-selection of weak magnetic minerals and rare metal ores less than 2-3 mm.

The Wet Magnetic Sorting Machine has no such geographical restrictions and is widely used in various mineral processing processes that require the participation of aqueous media.

Conclusion

To sum up, the main difference between dry magnetic separator and wet magnetic separator lies in their different working environment, applicable objects, process flow and application fields.

The dry magnetic separator is suitable for the separation of large and coarse-grained ores in a dry environment, while the wet magnetic separator is suitable for the separation process of fine-grained ores that require the participation of water medium.