What Should We Pay Attention To In The Inspection And Operation Of Wet Drum Magnetic Separator During Operation?

1.In the normal operation of the wet magnetic separator, in case of sudden shutdown, the equipment cannot be forcibly started before the cause is identified.

2.After the cause is identified, the materials in the wet magnetic separator must be cleared out before the machine can be started in order.

3.Pay attention to whether the sound of the wet magnetic separator is normal during operation, and deal with it in time when there is abnormal sound such as scraper and friction, and it is strictly forbidden to check the equipment during operation.

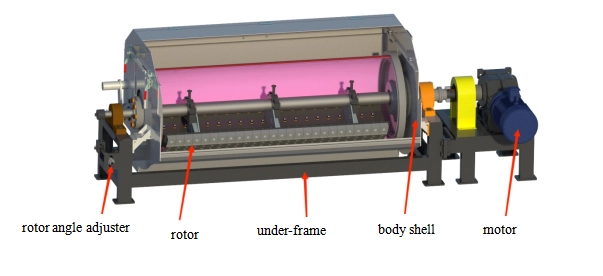

4.After the wet magnetic separator is shut down, the wear of the outer cylinder skin should also be checked. Only after the inspection of each of the above parts is normal, the start-up signal can be given, and then the device is started sequentially.

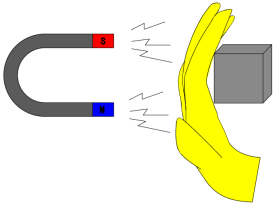

5.The wet magnetic separator is a high-magnetic application equipment, and it is not allowed to carry metal objects within 50cm of the magnetic roller regardless of stopping or starting.

How to Learn to Troubleshoot The Wet Magnetic Separator?

The occurrence of mechanical failure will lead to equipment downtime for maintenance, thereby reducing production efficiency and increasing production costs. Through the fault diagnosis of mechanical equipment, the fault can be found in time, quickly repaired, and the equipment can be avoided for a long time, thus improving production efficiency and reducing production costs.

| Serial Number | Common Fault | Fault Analysis | Troubleshooting Method |

| 1 | Magnetic Roller Abnormal Sound | The inner part of the magnetic roller falls off and scratches the steel cylinder | Inspection and maintenance of magnetic roller disassembled by professional personnel |

| 2 | Production Reduction | 1、The drum speed is not up to standard | Check the lubrication of the reducer |

| 2、There is a change in the water flow pressure of the material | Adjust the angle of the magnetic roller | ||

| 3 | The Bearing Temperature is Too High | 1、Insufficient lubricating oil | Add the appropriate amount of lubricating oil |

| 2、The lubricating oil is dirty and dirty | Replace the bearing with a new lubricating oil after cleaning | ||

| 3、Bearing damage | Replace the bearings |

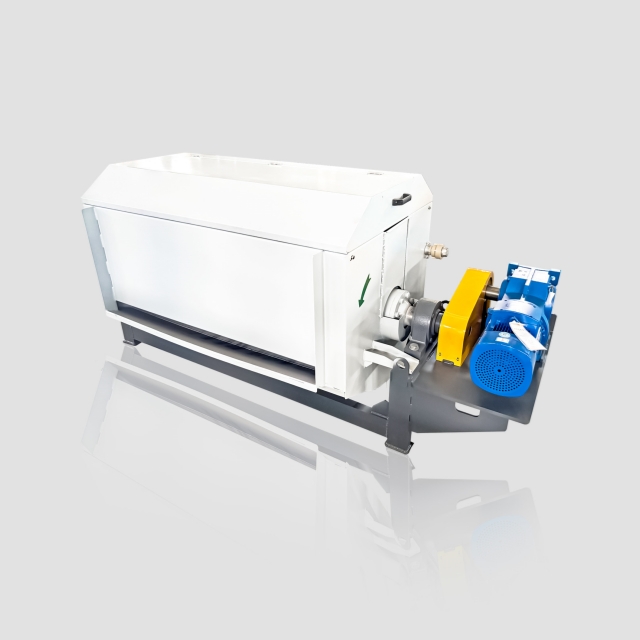

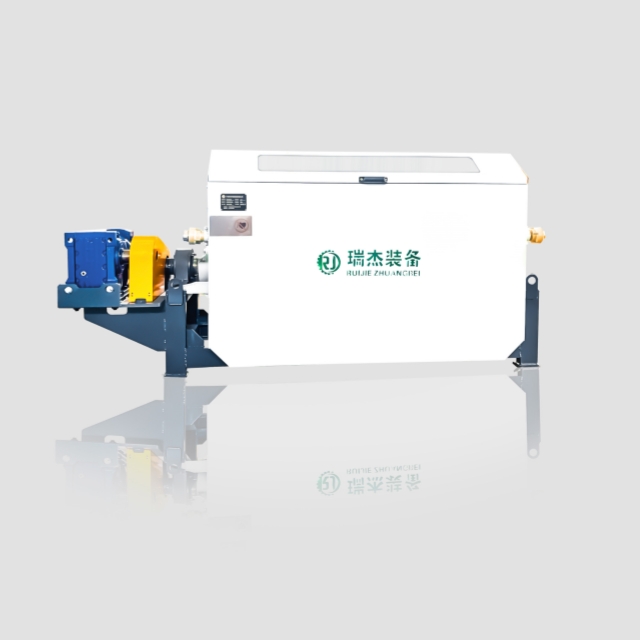

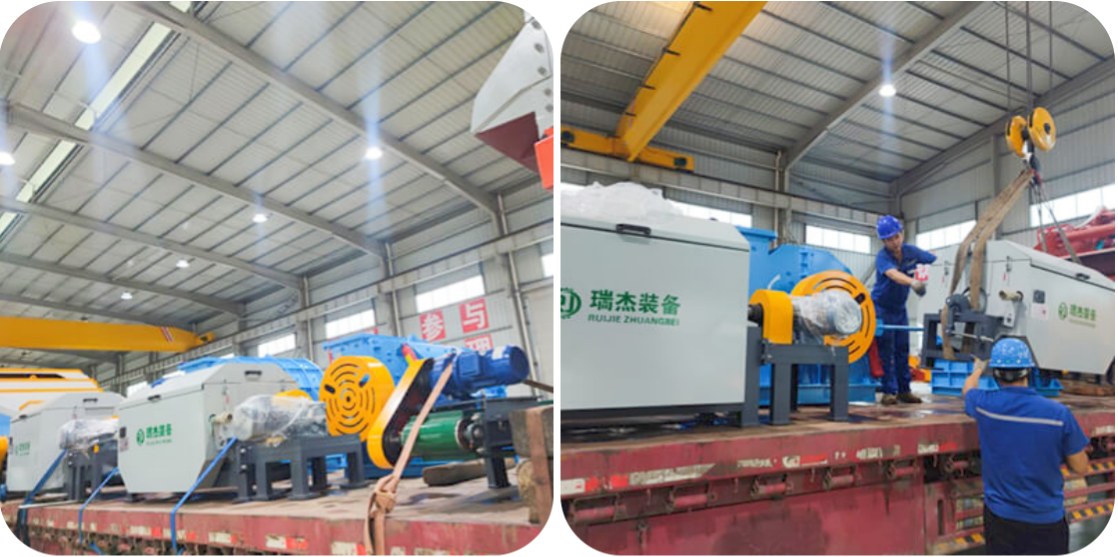

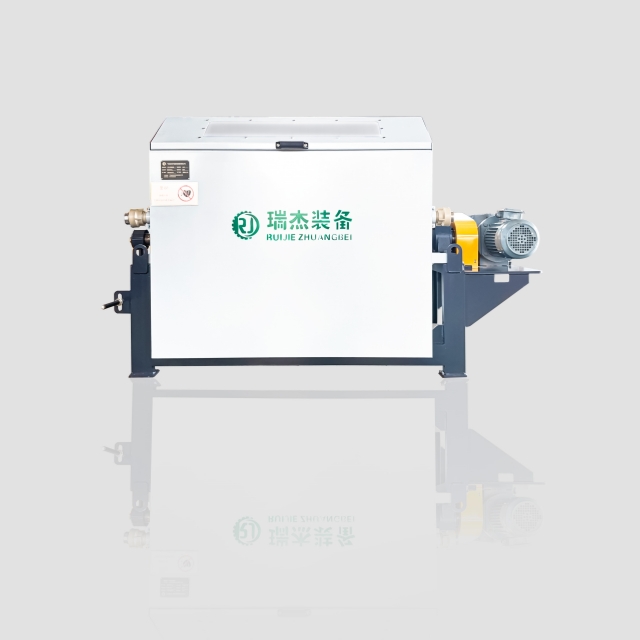

RUIJIE Wet Drum Magnetic Separator Delivery Site

Whether you are in mineral processing or magnetic metal resource recovery, we can provide you with tailor-made solutions to ensure that your production process is more efficient and accurate.