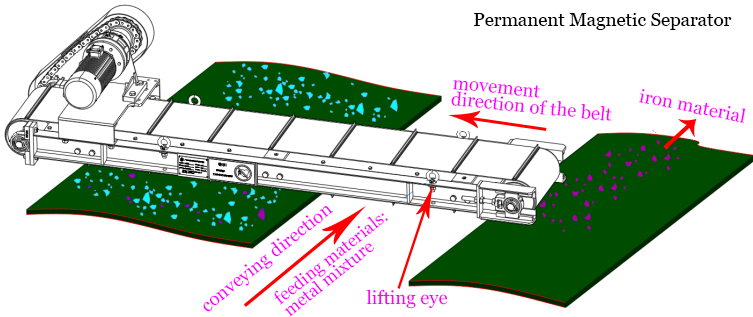

Precautions For The Use Of Suspended Permanent Magnets

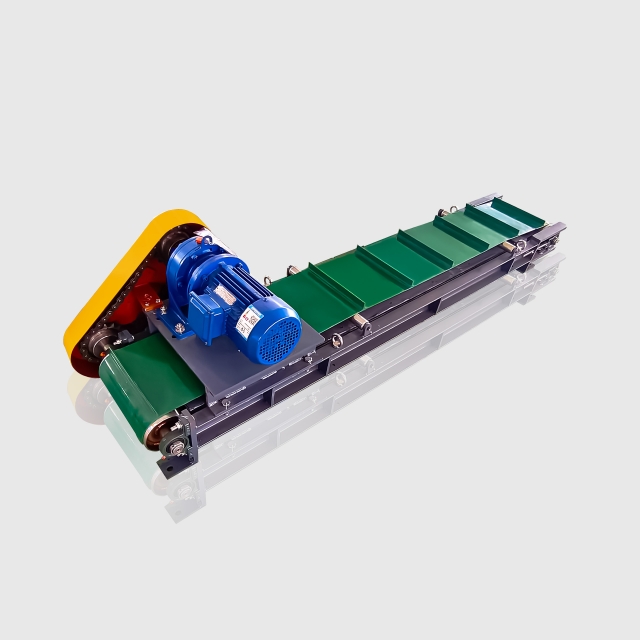

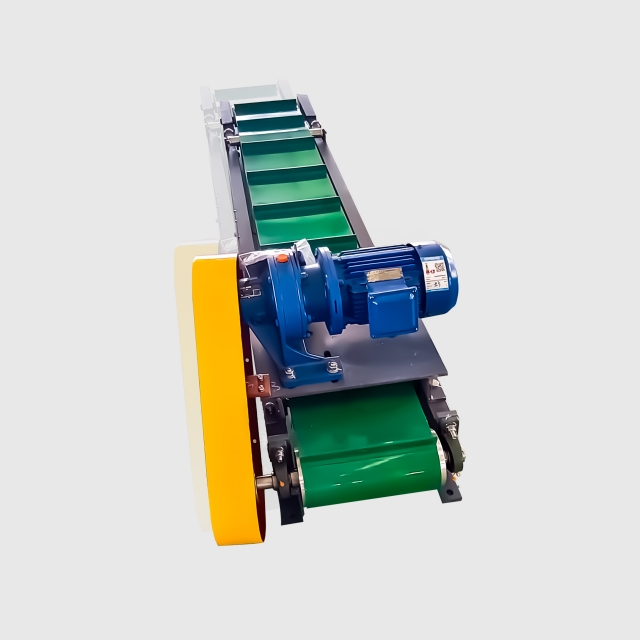

- The roller rotates at about 84 revolutions per minute. Therefore, before testing, carefully check for any foreign objects stuck between the roller and the belt. When starting the machine, closely monitor for abnormal noises.

- Under normal operating conditions, the temperature rise of the bearing should not exceed 40 °C, and the surface temperature should not exceed 80 °C. For safety purposes, the bearing temperature should not exceed 75 °C.

- As this is a strong magnetic equipment, iron objects are strickly prohibited within 50cm of the magnetic roller, whether the equiment is stopped or in operation.

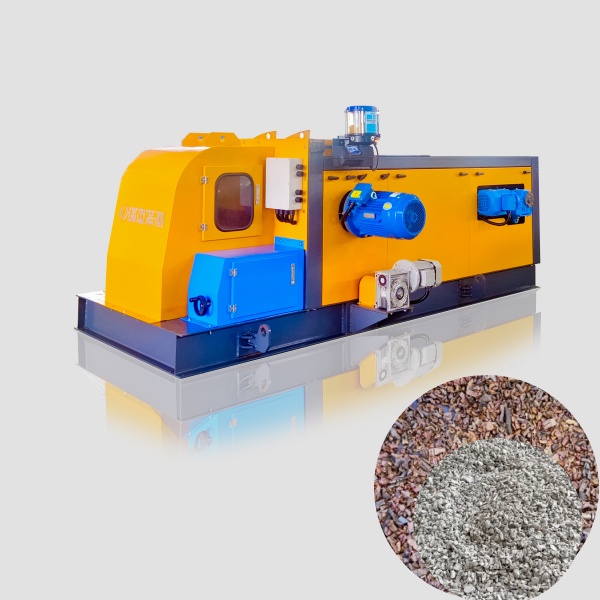

- The operation of suspended permanent magnet is controlled and monitored by the electrical cabinet. Please operate according to the markings on the electrical cabinet. In case of any equipment abnormality , please immediately press the red emergency stop button on the outer door of the electrical cabinet to prevent unnecessary losses.

When using the permanent magnetic equipment, please strictly observe the above precautions, or contact professional personnel for guidance.