Applications of the Slag Processing Equipment –Trommel Screens in Waste Management

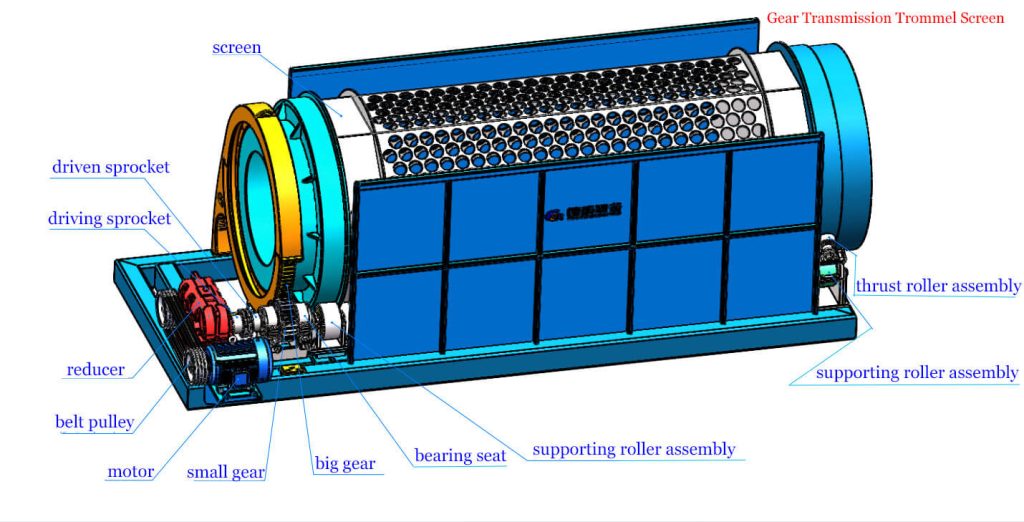

Trommel screens, also known as rotary screens or drum screens, are versatile and efficient machines widely used in electric power, mines, metallurgy, building materials, chemical industry and other production industry. They can be used for classify the particle size of materials, that makes them indispensable in modern waste processing facilities. Let us learn some key applications of trommel screens machine in waste management and their benefits.

1. Building materials and Demolition (C&D) Waste Recycling

Building and demolition waste often contains concrete, wood, metals, and plastics. Trommel screens would be used to:

- Sort debris by size, separating smaller particles from large materials like concrete blocks.

- Recover valuable materials such as metals for reuse.

- Improve recycling rates by ensuring clean and well-sorted material streams.

2. Electronic Waste (E-Waste) Recycling

Electric Power industries always produce electronic waste, E-waste contains valuable metals and hazardous materials. Trommel screens are used to:

- Separate small components (e.g., circuit boards, wires) from larger items like casings.

- Prepare materials for further processing, such as metal recovery or shredding.

- Improve safety by reducing manual handling of hazardous materials.

3. Slag Processing and Mining Waste

Trommel screens are also used in slag processing and mining waste management to:

- Separate valuable minerals from waste rock and slag.

- Classify materials for further processing or disposal.

- Reduce environmental impact by efficiently managing mining waste.

The trommel screen also can be applied for Municipal Solid Waste (MSW) Sorting, Composting and Organic Waste Processing, Biomass and Wood Waste Processing.

Why we use the slag processing equipment-trommel screen in waste Management?

- High Efficiency: with large processing capacity, able to process large volumes of waste quickly.

- Versatility: Suitable for a wide range of materials and applications.

- Durability: Designed to withstand harsh operating conditions.

- Low Maintenance: Simple design with minimal moving parts reduces downtime.

- Environmental Benefits: Promotes recycling and reduces landfill use.

Trommel screens are essential tools in modern waste management, offering efficient and versatile solutions for sorting and processing various types of waste in life and production industry.