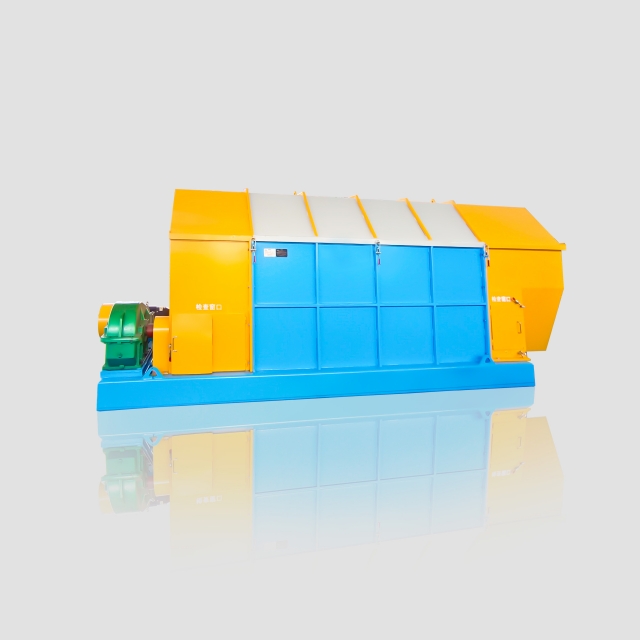

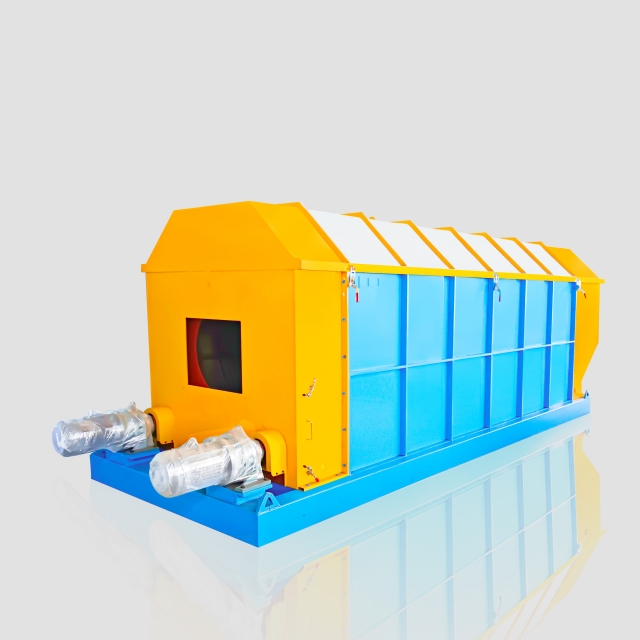

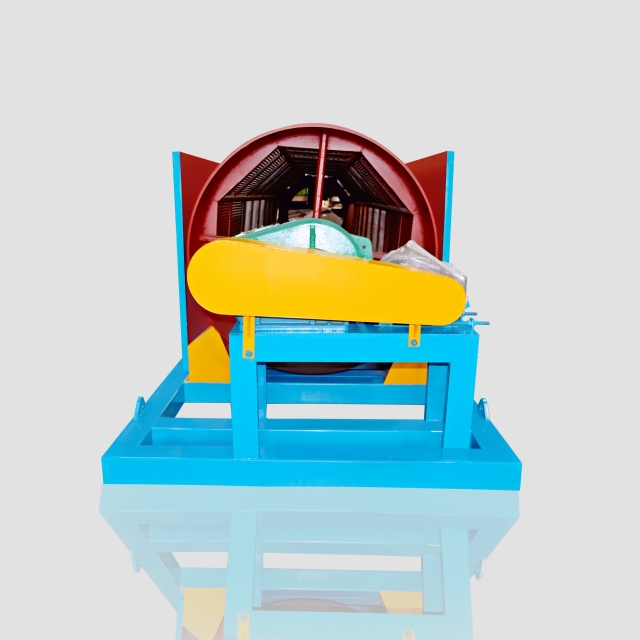

Series of Ruijie Drum Screening Machine

Here we show three series of Ruijie drum screening machine, including WGT series(drive wheel transmission), GT series(central shaft transmission) and GTC series( central shaft transmission).

They can be used to classify the particle size of material, and is widely used in electric power, mines, building materials and other production industries. you can contact us for more information and choose the right one for you project need.