What Problems Should Be Paid Attention To When Using Single-layer Eddy Current Separator?

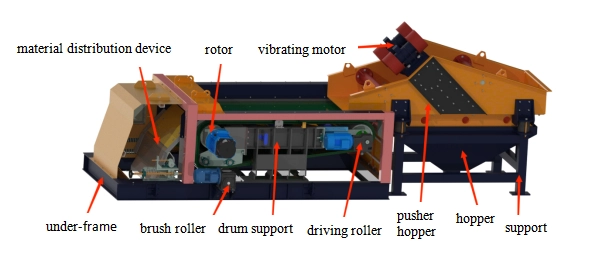

1.The eddy current separator and the vibrating feeder can be fed only after the normal operation.

2.Regularly check the condition of the belt, and remove it immediately if there is any waste that cannot be swept off.

3.Under normal circumstances, the temperature rise of the bearing shall not exceed 40°C, and the surface temperature shall not be higher than 80°C.

By measuring the temperature rise during the operation of the spindle bearing, we can know whether the spindle bearing is normal. If the temperature of the bearing is found to exceed 70-80°C during the monitoring, it should be stopped immediately for inspection.

4.Before stopping, the feeding operation should be stopped, and the motor can be turned off only after the materials in the eddy current separator and the vibrating feeder are completely separated.

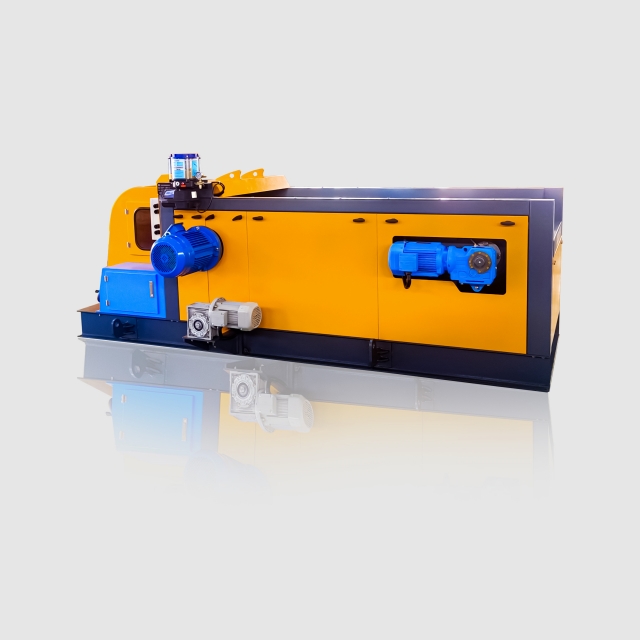

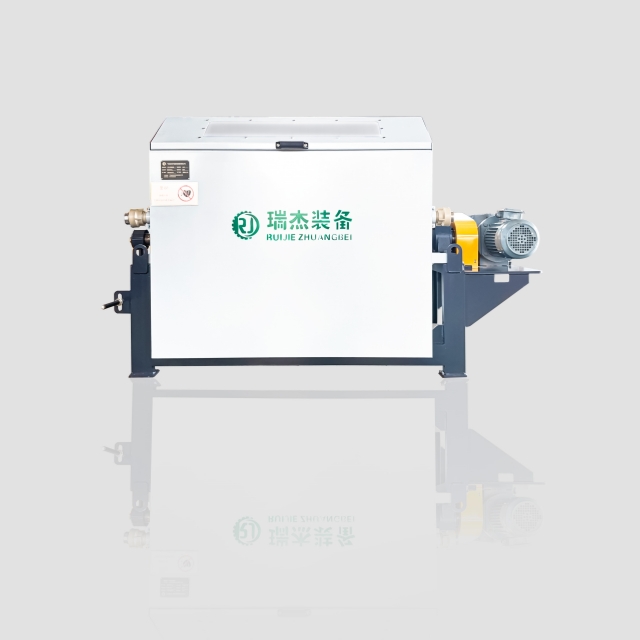

RUIJIE Single-layer Eddy Current Separator Sorts The Aluminum

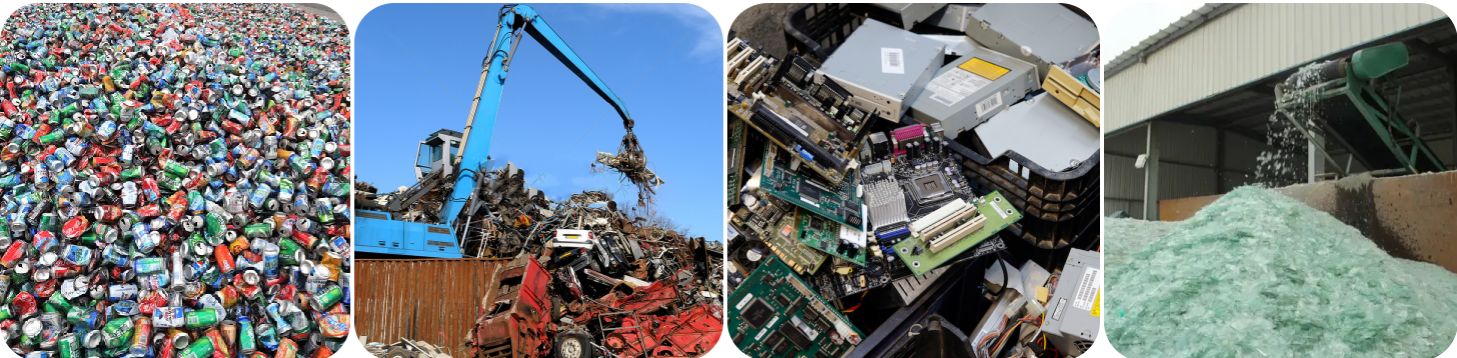

Single-layer Eddy Current Separator Solid Waste Sorting Project Application Site

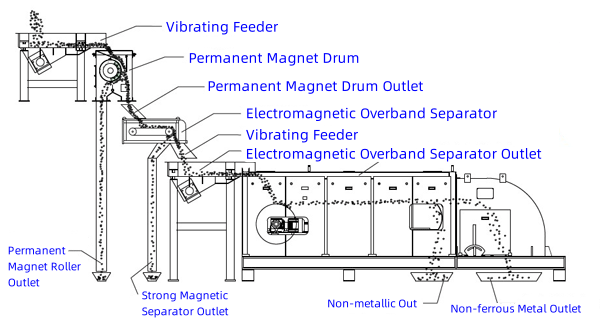

Eddy current sorting machine to achieve non-metal and non-ferrous metal separation for the purpose of solid waste materials copper, aluminum, zinc, plastic and other materials in the separation design of more than 2mm, instead of manual sorting problems, improve production efficiency, the sorting system can automatically separate non-metal and non-ferrous materials in the material.