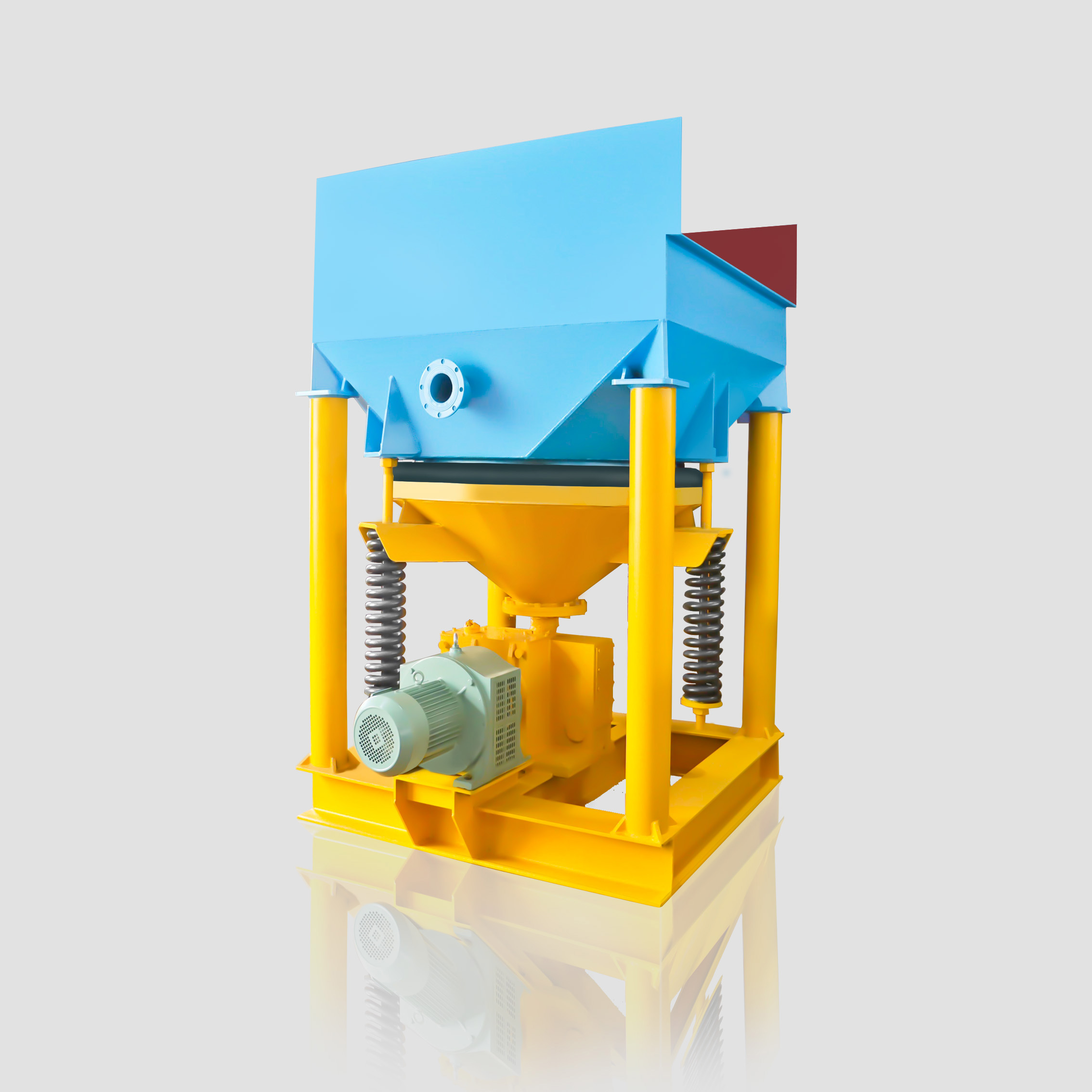

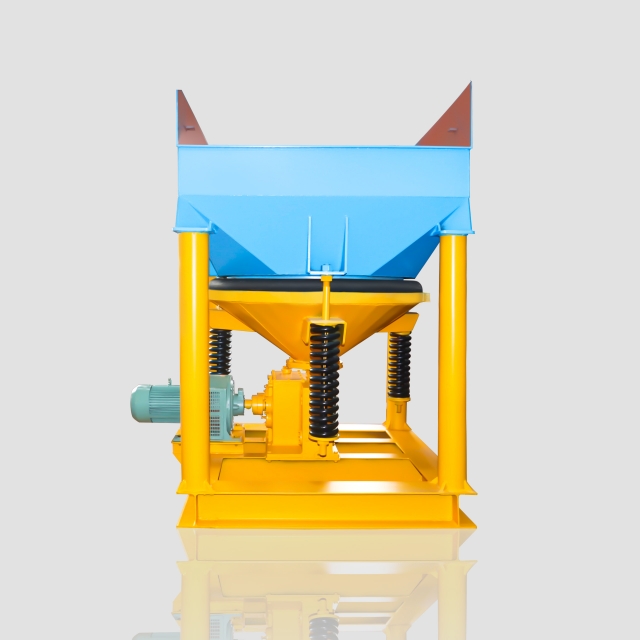

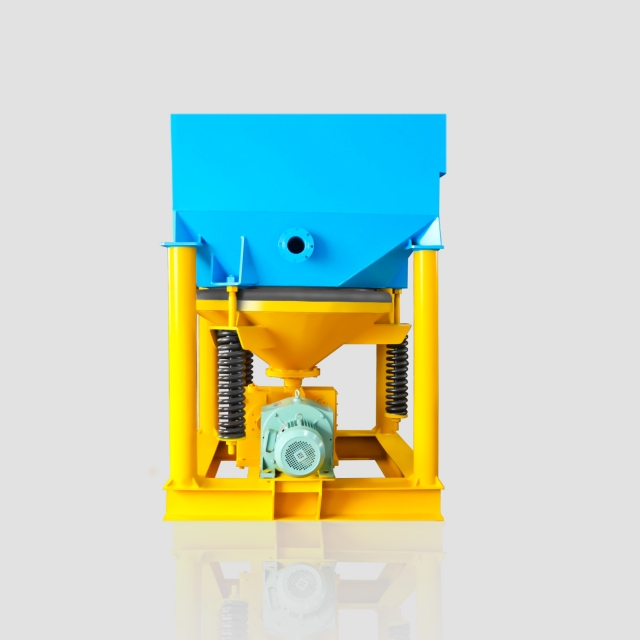

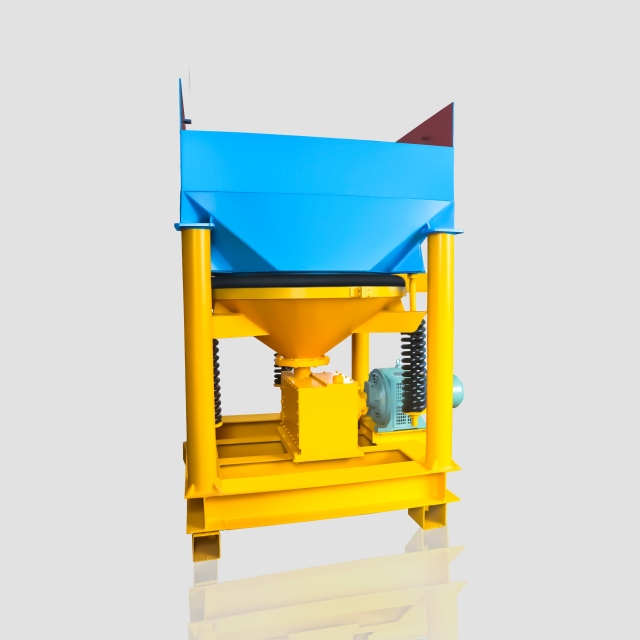

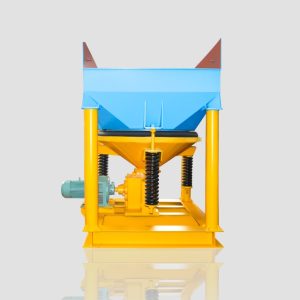

Why we choose the single chamber jig concentator?

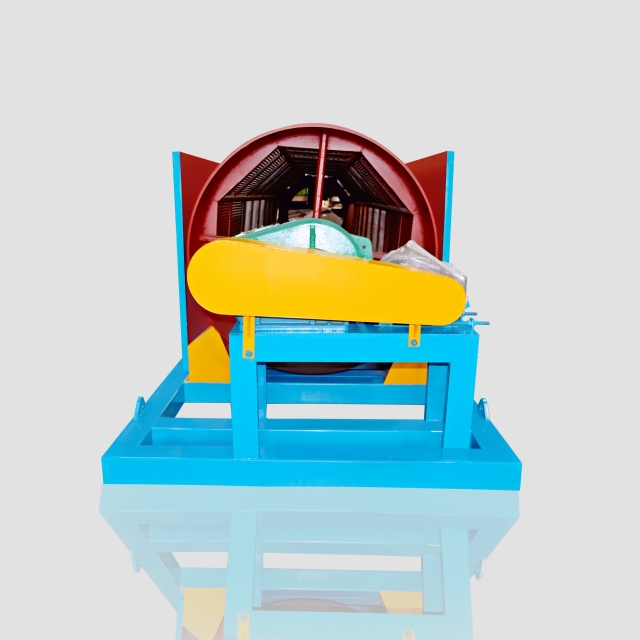

The single chamber jig machine is a gravity separation device based on the principle of specific gravity difference. It is suitable for small-scale separation of ores, metals, or other materials. Compared to double and triple chamber jig machines, the single chamber jig machine occupies less space and has lower costs, making it an ideal choice for small and medium-sized factories or industries with limited processing capacity.

Advantages of the single chamber jig concentrator machine

Compared with double chamber jig concentrator, three-chamber jig concentrator, the single chamber jig concentrator design is

- Space-saving, making it suitable for factories or sites with limited space

- Ideal for small-scale production or experimental separation.

- Lower manufacturing and maintenance costs.

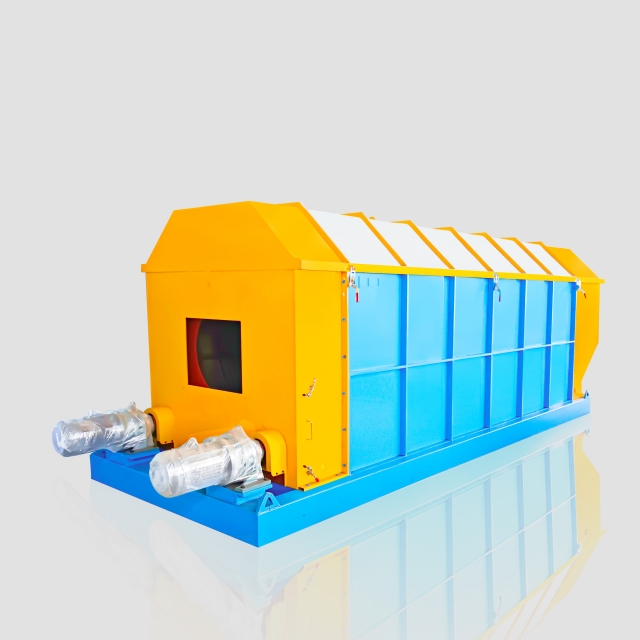

Where to use the single chamber jig machine

It can be used for separating metal ores, coal, gold sand, and other materials, suitable for small-scale ore separation, such as gold ore, tin ore, etc, scrap metal recycling

The cost-effective gravity sorting machine achieves efficient separation at a lower cost, making it ideal for small and medium-sized enterprises, suitable for various materials and scenarios, meeting the needs of different users.

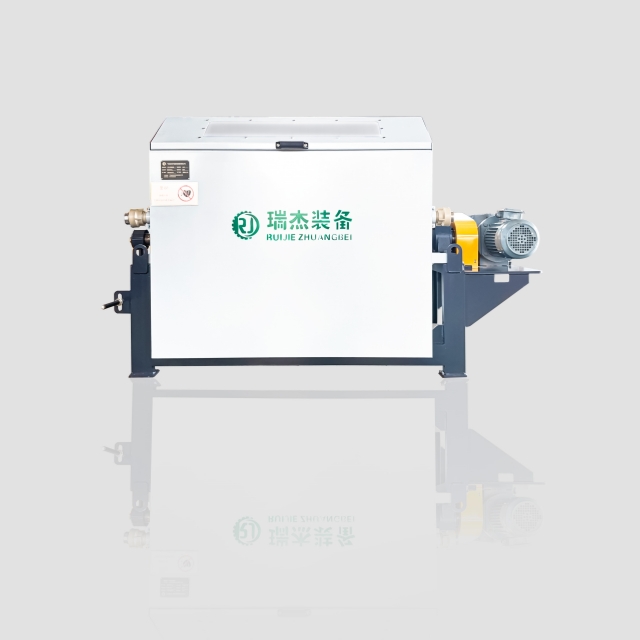

Ruijie Zhuangbei as a professional Manufacturer for slag sorting machine, the self-developed gravity sorting machine has been a great successful in recycling industry. Choose Ruijie to get a customized solution for your project!