Why We Use Magnetic Drum Separator for Magnetic Material Sorting?

Magnetic separators play a crucial role in the separation of valuable resources .

It is usually used for screen materials with the size no more than 3mm. Especially applied for incineration bottom ash sorting project. They are primarily used to recover magnetic metals (such as iron and nickel) by efficiently separating magnetic materials from non-magnetic ones through magnetic fields.

This process enhances resource recovery rates, reduces landfill waste, and minimizes environmental pollution. So, It is a good choice to choose a wet drum separator for screening fine iron materials.

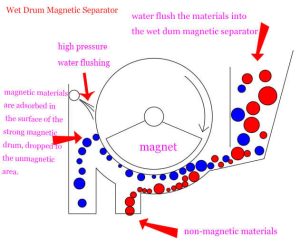

How does a Magnetic Drum Separator Work?

The rotary drum magnetic separator consists of a rotating drum with embedded magnetic poles. As materials flow over the drum, magnetic particles are attracted to its surface, while non-magnetic materials continue to move along the conveyor or discharge point. The strength of the magnetic field is adjusted based on the material being processed, ensuring efficient separation.

If you’re looking to increase product purity and streamline your operation, investing in a magnetic drum separator is a smart choice to improve efficiency and reduce waste.