How do you think of development trends of gravity sorting machine-jig concentrator?

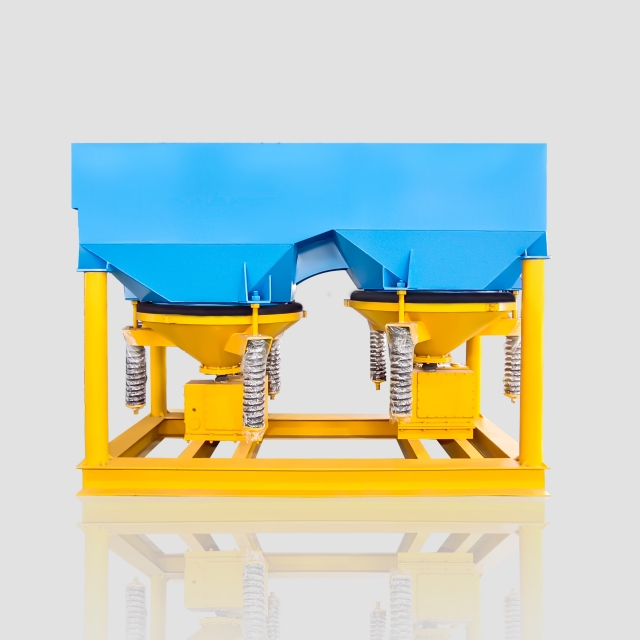

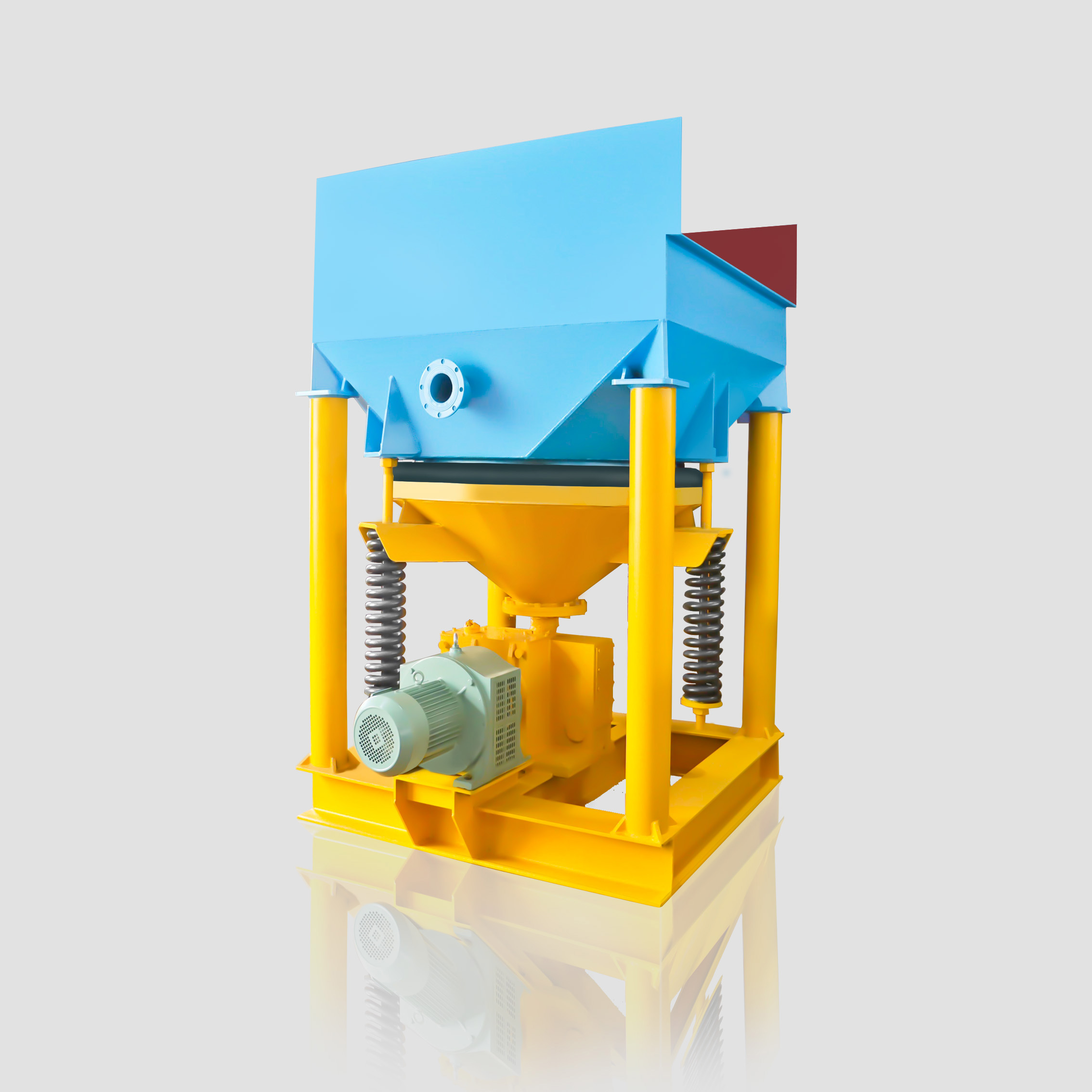

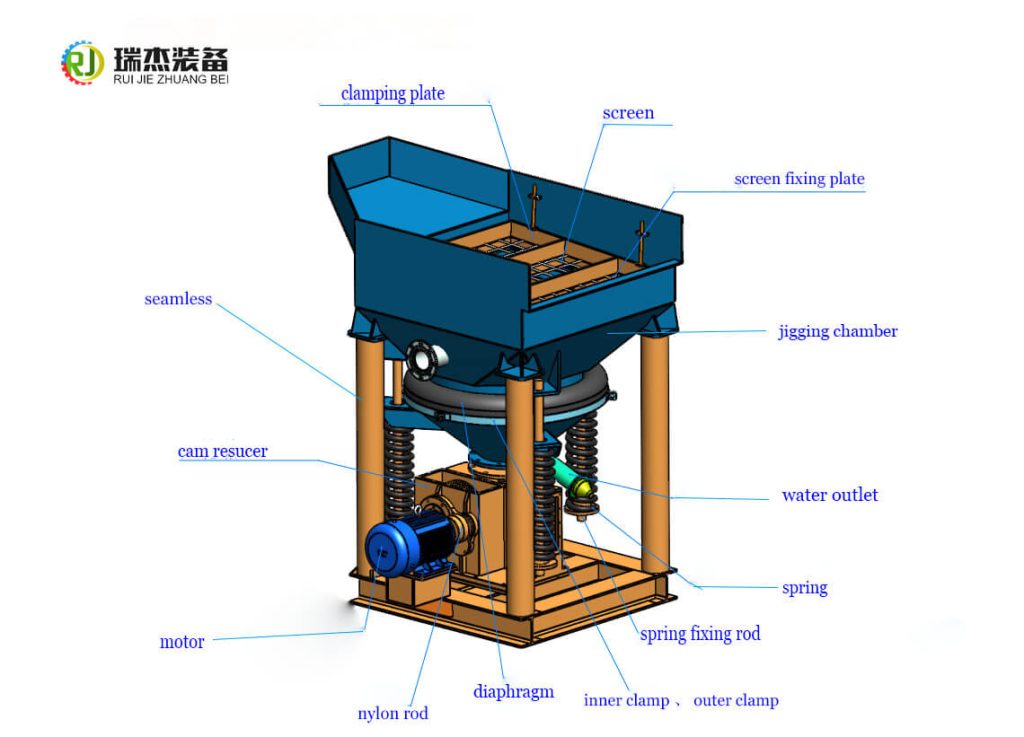

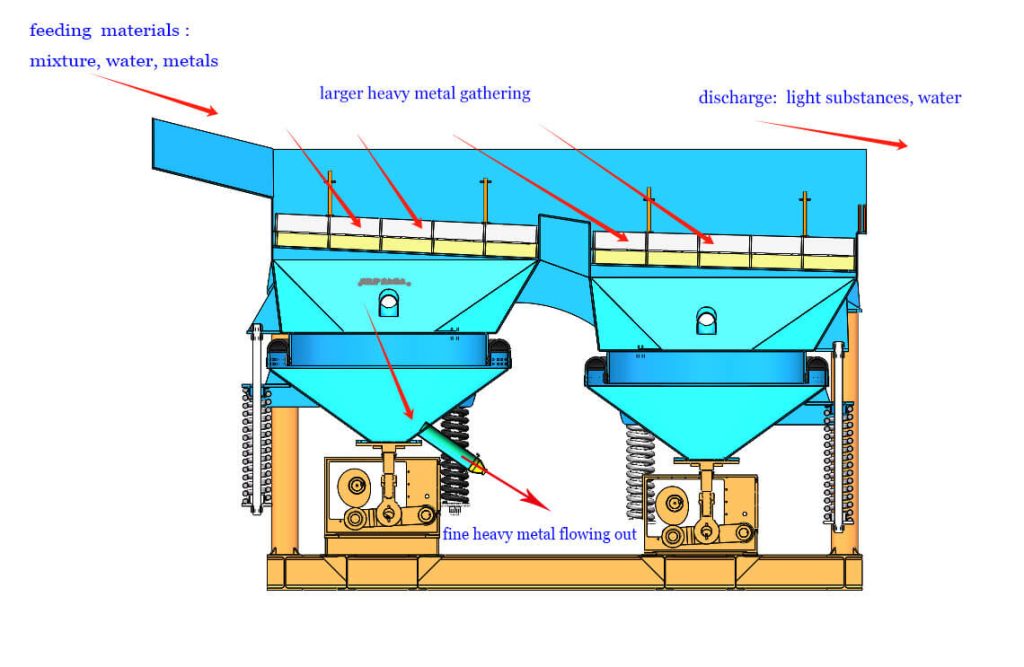

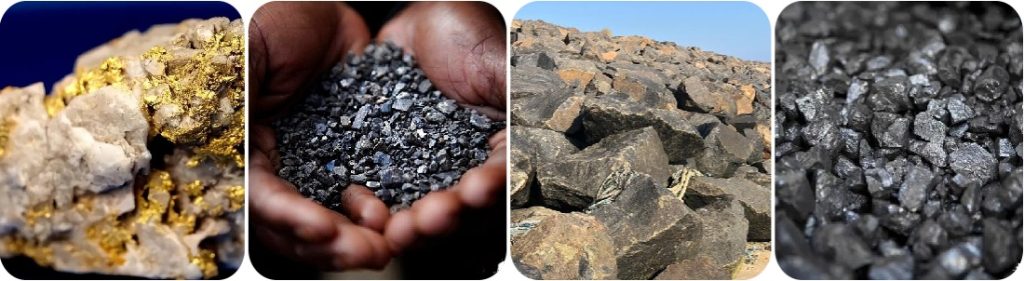

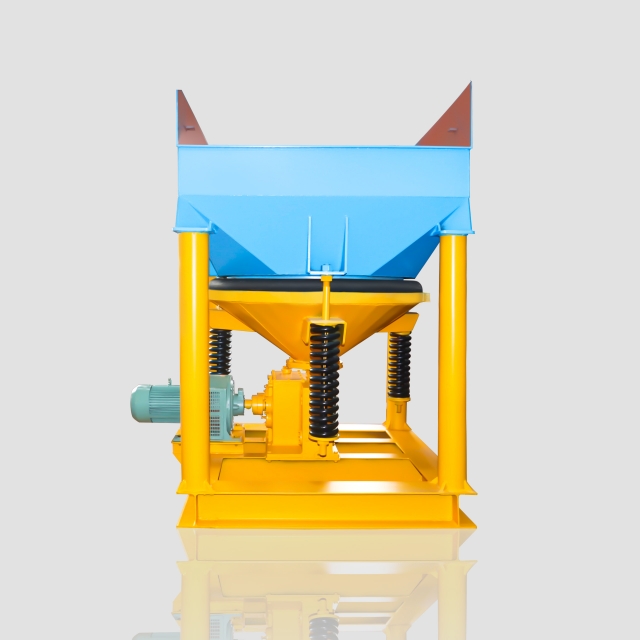

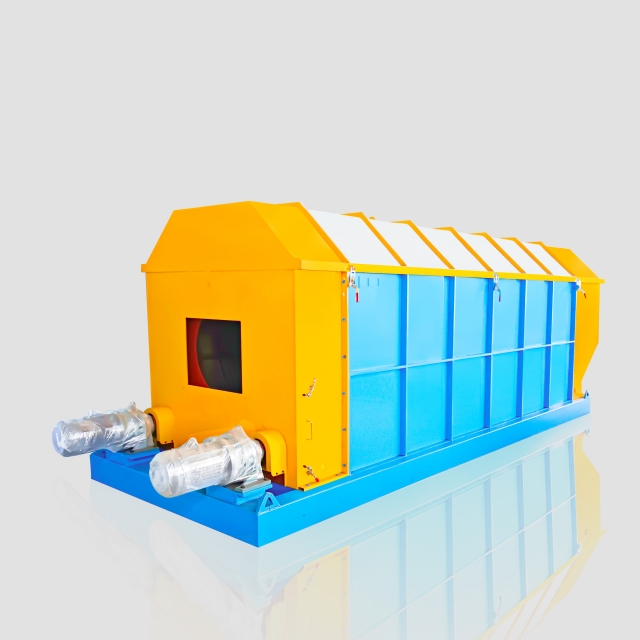

Slag jigging machines are essential equipment in the metallurgical and mining industries, designed to separate valuable metals from incineration bottom ash or mineral raw materials efficiently. With advancements in technology, these screen machines have evolved to offer higher performance, better energy efficiency, and improved environmental sustainability.

What we will do for the jig concentrator in the future?

- Increased Automation: Future jig separator machine will incorporate advanced automation technologies, such as AI and IoT, to enable real-time monitoring, predictive maintenance, and optimized performance.

- Integration with Smart Systems: The integration of smart systems will allow jigging machines to communicate with other equipment in the production line, enabling seamless coordination and improved productivity.

- Customization for Specific Applications: To meet the unique needs of different industries, jig separator machine will offer more customization options, such as adjustable separation parameters and modular designs.

- Adoption of Advanced Separation Technologies: Innovations in separation technologies, such as multi-stage jigging and hybrid systems, will further enhance the efficiency and precision of slag jigging machines.

As technology continues to advance, these machines will become even more efficient, automated, and sustainable, driving the industry toward a greener and more profitable future and we will continuously contribute to technology innovation and improvement.