High Sorting Efficiency Double-Layer Eddy Current Sorter

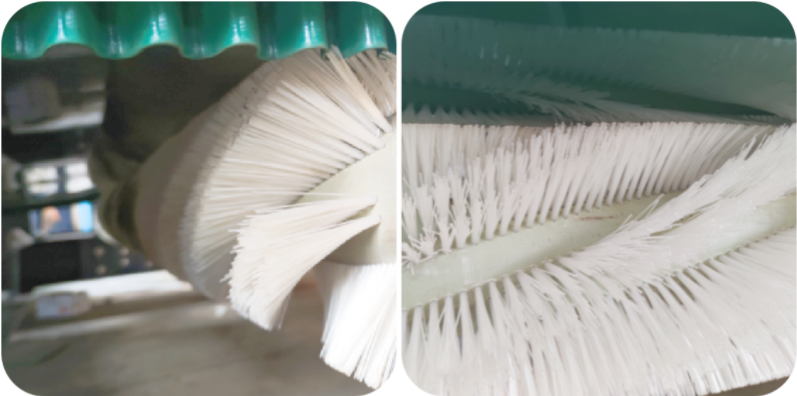

High sorting efficiency double layer eddy current sorter has important application value in the field of incineration bottom ash (IBA) wet separation and recovery. To improve sorting efficiency, we installed a sturdy, dense, acid-alkali-resistant, and highly durable nylon brushroll under the conveyor belt of each non-ferrous metals separator to enhance the sorting efficiency. These are specifically designed to effectively remove wet materials that are stuck to the surface of the belt.

Double-Layer Eddy Current Separator Saves Space

Double-Layer Eddy Current Separator Save space with only 6-7 square meters and enjoy the functions of two devices in the same space location.The double-layer non-ferrous metals sorting machine will carry out the sorting of materials twice, and the sorting purity and work efficiency are higher than that of the single-layer machine.

Double-layer Eddy Current Separator Solid Waste Weparation Project Application Site

With its compact, highly standardized modular system, you only need 6 to 7 square meters of floor space to achieve a high degree of automated material sorting. The system simplifies maintenance as the material is designed to be shipped from the same outlet, making the entire operation seamless.