How To Learn To Troubleshoot RUIJIE Durable Screw Conveyor?

Here we list a few troubleshoot samples of the screw conveyor, including fault conditions, fault causes, and machine exclusion measures for reference.

|

Fault Conditions |

Fault Cause |

Machine Exclusion Measure |

|

The Machine Is Not Running Smoothly |

Too much material |

Remove excess material |

|

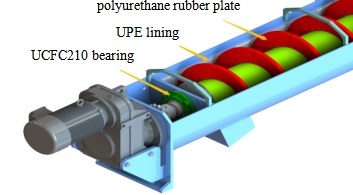

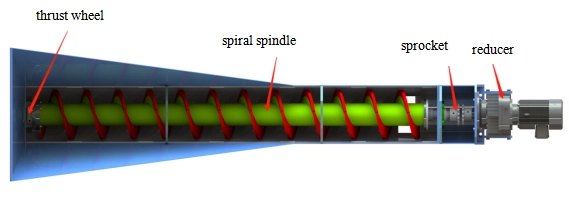

Damage to the propeller shaft bearing or tail shaft roller |

Add lubricating oil and replace if damaged |

|

|

The spiral spindle is bent |

The spiral spindle is straightened or replaced |

|

|

The polyurethane rubber sheet is broken or detached |

Replace the polyurethane rubber sheet |

|

|

The Machine Outlet Does Not Discharge Material |

Blockage |

Eliminate |

If you need any professional technology support or after-sales service, just feel free to contact us Guangxi Ruijie Slag Equipment Manufacturing Co., Ltd..