Double-deck Eddy Current Metal Separator Working Principle Video:

The material is fed into the vibrating feeder by the conveyor belt, and the vibrating feeder filters the moisture of the material through high-frequency vibration, and generates a forward thrust to evenly push the material into the double layer eddy current metal separator.

When the double-layer eddy current metal sorter works, with the rapid rotation of the magnetic drum, a strong magnetic field of high-frequency alternation is generated on the surface of the sorting drum, and when the non-ferrous metal passes through the magnetic field, it will generate eddy current inside, and the eddy current itself will produce a magnetic field opposite to the direction of the original magnetic field, and non-ferrous metals (such as copper, aluminum, etc.) will jump forward along its transportation direction due to the repulsive force of the magnetic field, so as to achieve the separation from other non-metallic substances and achieve the purpose of sorting.

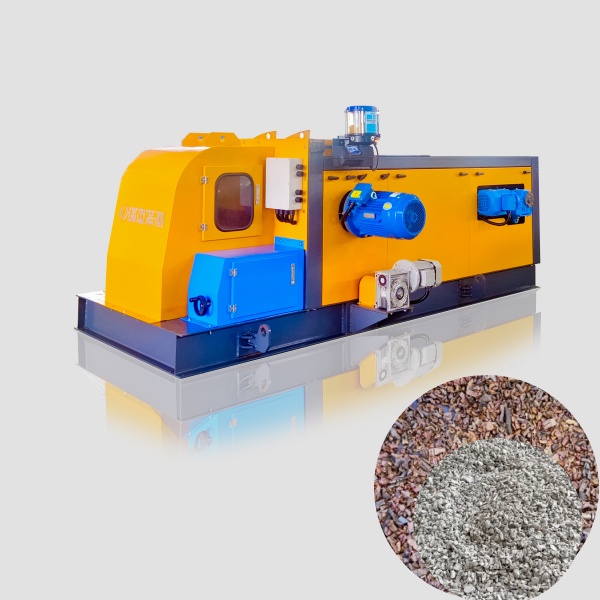

Double-deck Eddy Current Metal Separator Installation Site

The rated voltage of this equipment is 380V, the total power of single-layer equipment is 10.7kw, and the total power of double-layer equipment is 20kw. We need to configure the power cord according to the equipment, and grounding protection to prevent the wire from small load and overheating causing fire.

In order to achieve better sorting effect, we can adjust the distance and Angle between the parting plate and the magnetic roller according to the actual situation. The roller is used to adjust the distance, and the screw is used to adjust the Angle.