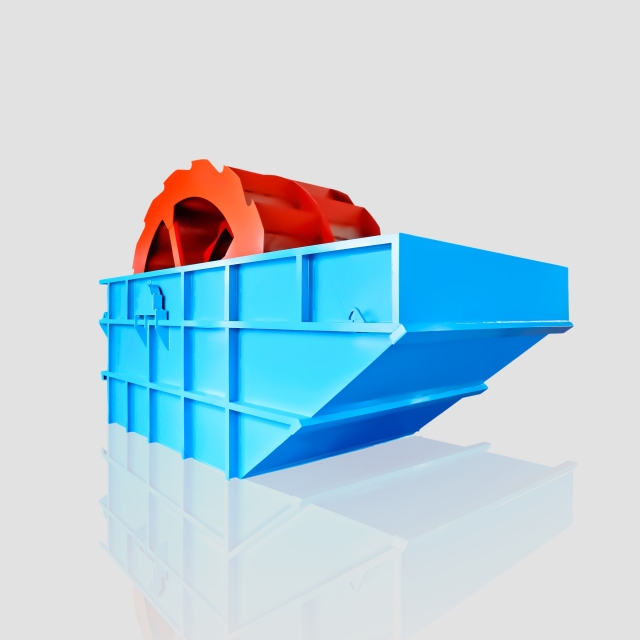

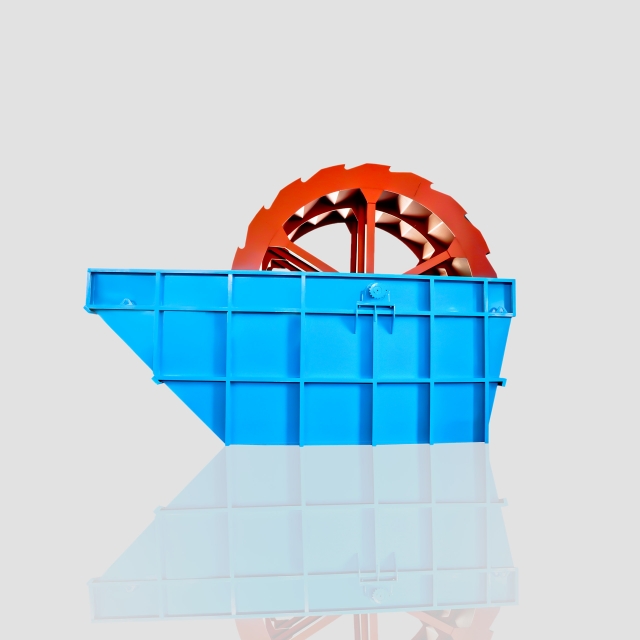

Wheel Bucket Sand Washing Machine China Manufaturer

Here shows the video about Bucket Wheel Sand Washer, in this video, we clean the sand inside the incineration ash (IBA), which also becomes environmentally friendly sand. RUIJIE ZHUANGBEI also can reasonably configure a full set of sand washing equipment for customers, including rock crushing and sand washing equipment. The sand washing plant has less fine sand loss and high sand quality, which can supply sand and gravel for high-rise buildings; At the same time, a sedimentation tank can be built to realize the recycling of water energy, save resources and green production.

The amount of investment required for a sand washing production line is also determined based on the actual production situation. It generally consists of two parts of capital, one part is the upfront investment, and the other part is the equipment investment cost.

RUIJIE ZHUANGBEI has more than ten years of experience in sand plant construction to meet the production needs of different users.

RUIJIE ZHUANGBEI technical manager for you to design the production plan, for you to configure a full set of equipment, the price is preferential.

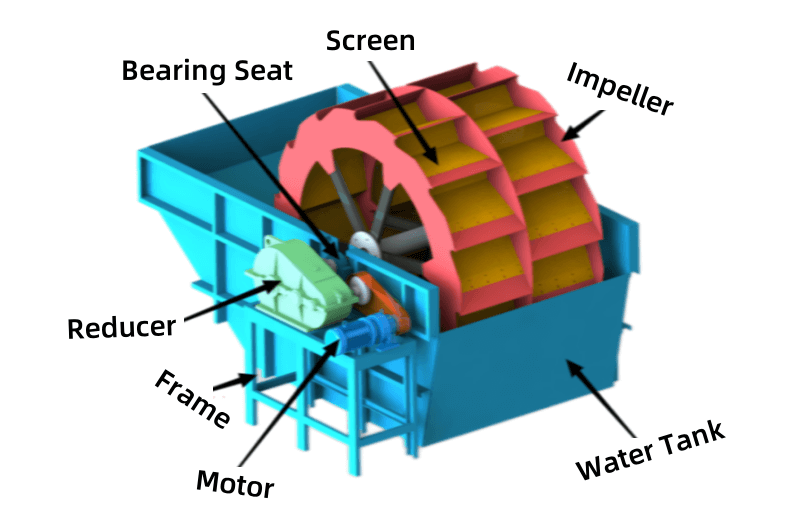

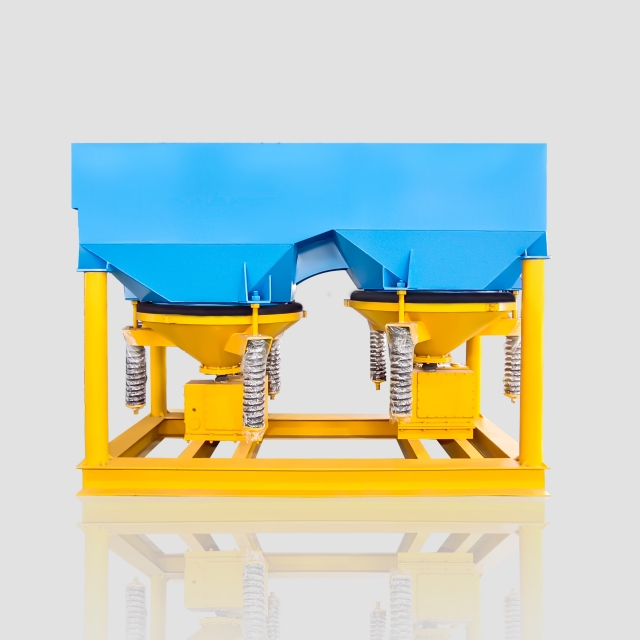

There are three kinds of common sand washing equipment: spiral sand washing machine, impeller sand washing machine and vibrating dewatering screen, which are widely used in sand and gravel production lines, mining,Incineration Bottom Ash (IBA), building materials and other fields to wash, classify and dehydrate raw materials.

1000T /D Sand Making process For Building Materials

How To Learn To Troubleshoot The Bucket Wheel Sand Washer ?

|

Common Fault |

Causes |

Elimination Methods |

| Reduced Sand Washing or Sand Leakage | The sand net is damaged | Check and repair or replace the sand mesh |

| The sand net fixing bolt falls off | fastening bolt | |

| Frame Vibration | The coupling frame bolts are loose | fastening bolt |

| Loose housing bolts | Check and tighten the bolts | |

| The Transmission Part is Noisy | Insufficient lubrication of gears | Add enough grease and adjust the reducer |

| Gear spacing varies | Anchor bolts and tighten | |

| Gear Wearing Parts | Not maintained in time | Refuel at the specified time |

| The shaft of the sand washer and the low-speed shaft of the reducer did not reach the specified parallelism | Adjust it to meet the requirements | |

| Bearing Wearing Parts | Oil cut-off or damaged seals | Refill or replace seals on time |

| Chronic lack of repair and cleaning | Wash regularly |