Some Maintain Suggestions about Automated Copper Hammer Crusher

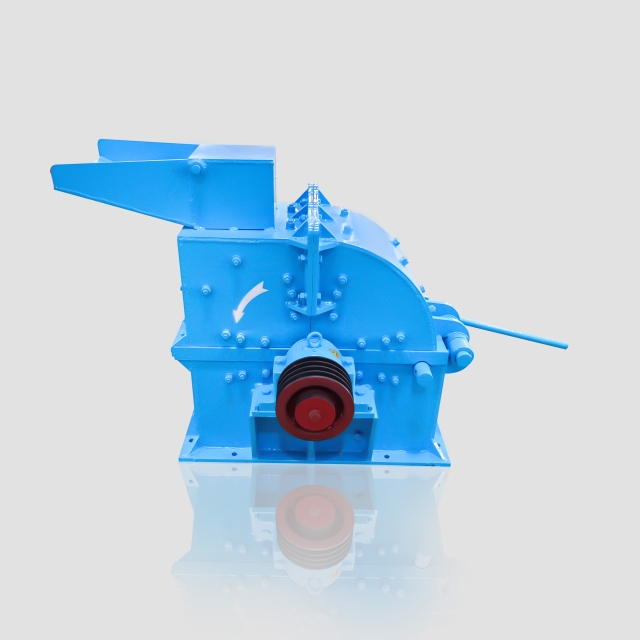

The automated copper hammer crusher is widely used to crush all kinds of hard and corrosive materials, there are some maintain suggestion for it.

1. Regularly inspect the key components of the Automated copper hammer crusher, such as the copper head, bearings, and transmission devices.

2.Regularly check the wear of the copper head and replace severely worn heads promptly to maintain crushing efficiency.

3.Monitor the equipment temperature during operation to avoid overheating and component damage.

4.Regularly inspect the transmission components, such as belts and chains to ensure proper tension and avoid slippage or breakage

5.Regularly inspect the electrical wiring and control systems to ensure secure connections and avoid downtime due to electrical failures.

6.Provide regular training for operators to ensure they are familiar with equipment operation and maintenance procedures, reducing human errors.

7.Keep a maintenance log to record each inspection, maintenance, and part replacement, making it easier to track equipment status.

To ensure the equipment operate stably, effectively, prolong its service time, the regular inspection is necessary.

If you need more detail information for maintenance or technology support, just contact us Ruijie Slag Equipment.