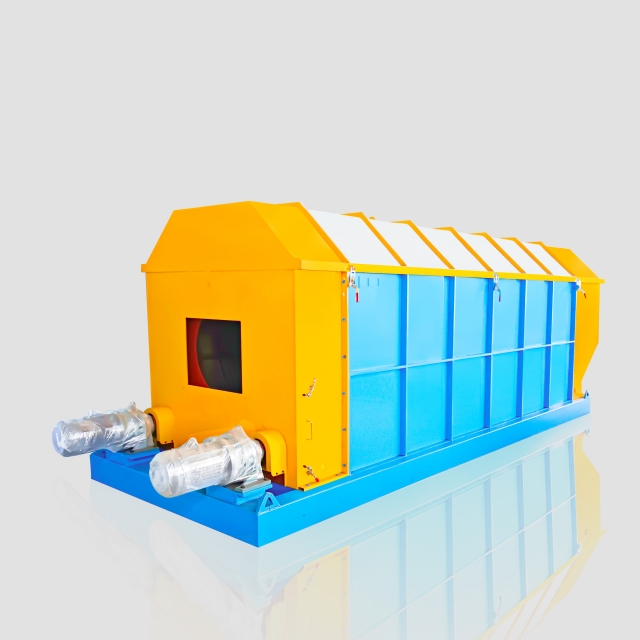

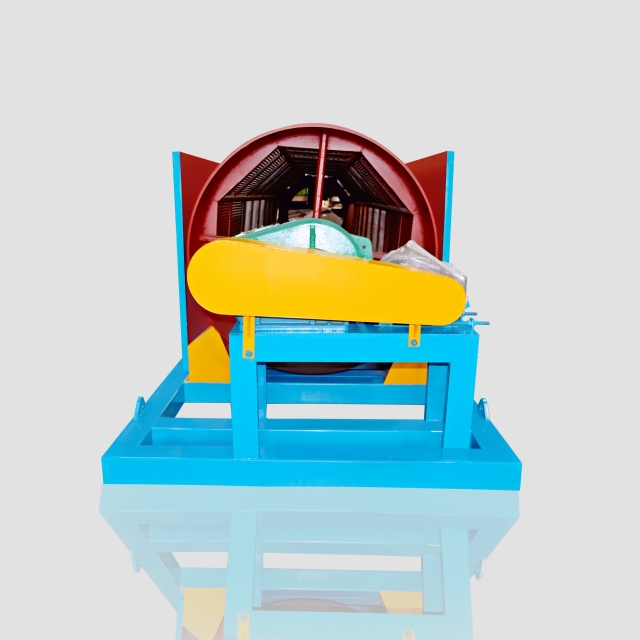

Best Customized Trommel Screen Machine China Manufacturer

Trommel Machine is mainly suitable for the particle size grading treatment of various solid wastes, with simple process, and is suitable for domestic garbage, construction waste, scrap metal, as well as mining, building materials, Incineration bottom ash (IBA) sorting and other industries.

Trommel Screen Machine Features

1.The position of the large ring at both ends of the machine is machined, and the supporting roller is made of thickened material, which has better stability.

2.Gear Ring Trommel Screen: The gear ring drive makes the equipment more stable, the heavy load will not slip, and the sorting efficiency is high.

3.The screen of the trommel screen is made of 201 stainless steel, which has good corrosion resistance and longer service life.

Why Choose RUIJIE Trommel Screen Separator for Stone, Sand, Solid Waste Separation And More?

FAQs

You may be asking if the equipment can be customized to specific needs, such as screen pore size, screen material, screen length, or overall size of the equipment (large or small trommel screen), whether it can be adapted to specific material characteristics or work scenarios.

Our answer is yes, we usually support custom designs to meet the specific needs of users. Here are a few aspects of custom design:

1.Screen Aperture and Material:

The mesh pore size of the trommel screen can be customized according to the type of material being processed and the particle size.

For example, for small granular materials that need to be finely screened, a smaller pore size can be selected; For handling large particles or coarse materials, a larger pore size can be selected.

The material of the screen can also be customized according to the abrasive nature of the material, common materials include steel, stainless steel and wear-resistant materials.

2.Equipment Size and Capacity:

The overall size, screen length and diameter of the trommel screen can be adjusted according to the user’s throughput needs.

Larger projects may require larger equipment to handle more material, while smaller projects can opt for compact equipment to save space.

3.Power System:

According to the needs of users, the trommel screen can be equipped with motors or transmission systems of different power to adapt to different working intensity and material characteristics. For example, users can choose higher power motors to handle heavy loads.

4.Anti-clogging Design:

For users who handle wet or sticky materials, trommel screens can be equipped with a self-cleaning design to prevent material from clogging the screen. The special screen design can increase the screening efficiency and reduce the frequency of maintenance.

5.Environmental Protection and Safety Features:

The trommel screen can be equipped with dust removal device, sealing isolation cover and safety protection system according to different working environments to ensure that the equipment meets local environmental protection and safety standards.

6.Mobile Design:

If users need to move equipment between different workplaces, it can be customized to be a mobile trommel screen, equipped with wheels or bases, making it more flexible and convenient to use in different sites.

In short, the customized design of RUIJIE Trommel Screen can be adjusted according to the user’s material characteristics, working conditions and capacity requirements to ensure that the equipment can meet specific application scenarios.

Users can communicate with RUIJIE Manufacturer according to their needs to get suitable solutions.

Trommel Screening Machine belongs to the screening equipment in the relatively large processing equipment, although there is no magnetic separator, sorter and other complex structure, but the use of the process of processing is larger, therefore, in the process of long-term use will inevitably appear some mechanical failures, today Xiaobian summarized the following more important is also prone to failure, and gave the corresponding solutions, I hope to help you.

- The Bolts of The Equipment are Loose

When the bolts of the trommel screen are loose, it is easy to cause the equipment to work with noise, so it is enough to re-tighten the bolts or other fasteners.

- The Rotation Direction of The Trommel Screen is Wrong

The wrong connection of the motor power cable will cause the trommel screen to rotate in the wrong direction, just replace the power cable in the junction box.

- The Motor Starts Slowly

The conveying capacity exceeds the allowable value, the motor is overloaded, and the torque is not enough when the motor is started, etc., which will lead to the slow start of the trommel screen motor. In this case, it is necessary to readjust the conveying volume.

- The Gearbox is Heated

This can happen when there is insufficient ventilation or lubricant in the enclosure and the vents should be checked and adjusted for heat dissipation and lubricant should be added.

- The Motor is Heated

The cooling time of the motor is too short, the working environment of the motor is greater than 40 degrees, the motor is overloaded, the motor connection line is loose and the star triangle wiring of the motor is wrong.

- The Sieve Hole is Blocked

The garbage blocked by the sieve hole should be cleaned up in time to reduce the blockage.

- Heating At the Bearing

Check the bearing in time, whether the lubricant is distributed in place, add lubricant, and replace it in time if the bearing is seriously worn.