High Performance Screening Machine From China Manufacturer & Supplier

At RUIJIE, we specialize in providing high-performance screening machines designed for industrial material sorting and separation processes. Our screening machines are essential in a variety of industries, from mining and construction to recycling industry. Whether you’re looking to separate fine particles or dewater materials, our machines deliver precise, reliable, and efficient performance.

Features of Our Screening Machines

- The eccentric block integrated vibrating motor is adopted, which further improves the screening efficiency and ensures the quality of the product.

- Equipped with a highly wear-resistant and anti-clogging polyurethane screen, this screen has a high degree of modularity and is easy to replace.

- The stressed wearing parts of the trommel screen are thickened and specially treated to make them more stable and durable.

- The machine adopts customized Q355B high-strength sheet, which has higher strength and stability, and longer service life.

Types of Screening Machines Offered by RUIJIE

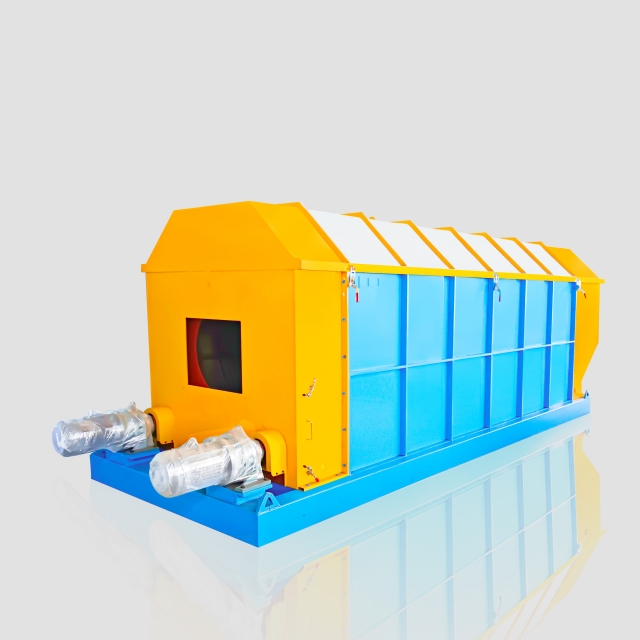

1. Trommel Screen: A Versatile Solution for Fine Material Separation

Our Trommel Screen is widely recognized for its reliability and high throughput. Ideal for separating materials by size, it utilizes a rotating drum with screen apertures to filter and sort materials efficiently. The trommel screen is perfect for processing sand, ores and other bulk materials. With varying screen mesh sizes, it ensures accurate separation of fine and coarse particles, optimizing production and minimizing waste.

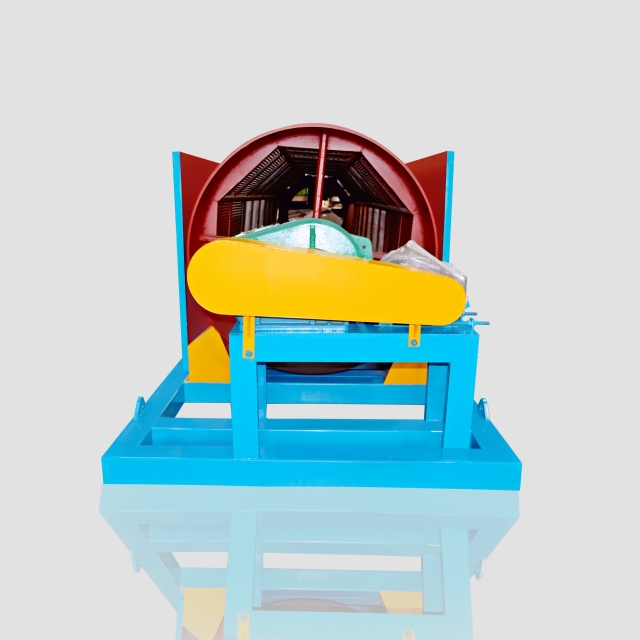

2. Vibrating Dewatering Screen: Efficient Moisture Removal for Wet Materials

The Vibrating Dewatering Screen by RUIJIE is specifically designed for efficient dewatering and separation of wet materials. This high-frequency vibrating screen ensures that liquids are separated from solids, leaving you with a dry, easily manageable product. Ideal for applications in industries such as mineral processing, this dewatering screen helps remove impurities and ensure the quality of the target product by reducing moisture content in the material.

Why Choose RUIJIE's Screening Machines For Mining and Recycling Industry?

Choose RUIJIE screening machine to perfectly meet the separation needs of incineration bottom ash, sand and gravel aggregate and other fields.

Our equipment is known for its efficiency and durability to help you increase your productivity. Inquire now and get a free quote to provide the best solution for your project!

Key Benefits of RUIJIE Industrial Screening Machines

- High Capacity

our industrial screening machines are designed to handle large volumes of material efficiently. Whether processing ores, sand, or construction materials, our machines maintain high throughput. This capability rspeeds up production. - Durability

Our screening machines are made with robust materials that perform well in harsh industrial conditions. They can endure heavy vibrations and extreme environments. This durability ensures longer lifespans and lowers maintenance costs. - Customizable

We offer customizable screening machines to meet specific needs. Choose from various sizes and screen configurations. Whether you need a trommel screen or a dewatering screen, we provide solutions tailored to your operations. - Efficient Material Separation

Our machines ensure precise, uniform sorting of materials. Whether separating by size, weight, or other properties, our machines improve productivity. This efficiency helps reduce material waste and optimize your production process. - Energy-Efficient

RUIJIE’s screening machines are designed to reduce energy consumption while maintaining excellent performance. Their energy-efficient operation lowers costs and supports sustainable practices.

Applications of Screening Machines

RUIJIE‘s industrial screening machines are essential in the mining and recycling industries. Our machines excel at the efficient screening and separation of materials, particularly those that are recyclable or reusable, ensuring that valuable resources are recovered and waste is minimized.

- In mining, RUIJIE screening machines play a vital role in sorting minerals and ores. These machines help separate valuable materials.

- For the recycling industry, our machines help separate recyclable materials, like metals, plastics, and glass, from waste.

RUIJIE machines are key in the separation of reusable materials across various industries. Whether recovering materials from construction debris or from e-waste, our screening machines ensure that only valuable resources move forward in the process.

FAQs

The remote monitoring and control function of RUIJIE dewatering screen can help users monitor the status of equipment in real time, improve production efficiency, and find and solve potential problems in time.

The following are the key contents about the remote monitoring and control of RUIJIE dewatering screens:

1.The Feasibility Of RUIJIE Remote Monitoring

- Real-time Data Monitoring: Modern dewatering screens can often integrate sensors, data acquisition devices, and remote communication modules, allowing users to remotely monitor the operating status of equipment through industrial control systems (e.g., SCADA, DCS systems).

Through these systems, users can monitor key parameters such as vibration frequency, operating temperature, processing capacity, and so on.

- Data Recording And Analysis: The remote monitoring system can record equipment operation data and store it for a long time, which is convenient for users to analyze data and troubleshoot. For example, users can analyze the operating trends of equipment by analyzing historical data to determine whether maintenance or replacement parts are needed.

2.RUIJIE Remote Control Function

- Equipment Start And Stop: Through the remote control system, the user can start or stop the dewatering screen equipment remotely. This is especially important in remote or unmanned plants, where users can operate the equipment remotely from a central control room or mobile device, increasing operational flexibility.

- Vibration Frequency and Amplitude Adjustment: Some high-end dewatering screens support remote adjustment of vibration frequency and amplitude to adapt to the processing needs of different materials. Users can remotely adjust the equipment parameters according to the actual production situation to ensure the best dewatering effect.

- Alarm System and Automatic Response: Remote monitoring systems usually integrate alarm functions, and the system will automatically send out an alarm if the operating parameters of the equipment are outside the preset range (such as excessive vibration, excessive temperature, etc.). Some systems support an automatic response mechanism that can automatically stop the equipment or adjust the operating status when a problem is detected to avoid further damage to the equipment.

3.Integration Into Existing Industrial Control Systems

1.Most modern dewatering screens can be integrated with existing industrial control systems (e.g. SCADA, PLC, DCS) via standard communication protocols (e.g. Modbus, Profibus, Ethernet/IP, etc.). This compatibility allows the dewatering screen to be seamlessly integrated into the user’s existing production automation network.

2.Through the integration with the existing control system, users can monitor and control multiple dewatering screens and other related equipment at the same time in the central control room, enabling centralized management of the entire production process. This increases productivity and reduces manual intervention.

4.RUIJIE Remote Maintenance And Fault Diagnosis

1.Through the remote monitoring system, technical support personnel can remotely view the running status and historical data of the equipment to help users troubleshoot. This capability reduces on-site repair time and can sometimes even resolve issues directly from a remote system without the need to send a technician to the site.

2.Users can view and operate the equipment remotely through a dedicated software platform, such as a SCADA system or customized monitoring software. Our system also supports apps on mobile devices such as phones or tablets, allowing users to monitor devices anytime, anywhere.

5.Advantages Of Remote Monitoring And Control

1.Through real-time monitoring, users can manage equipment more flexibly and maximize the operational efficiency and productivity of equipment.

2.Remote monitoring and control reduces the need for operators to manage equipment on-site, reduces labor costs, and enables rapid action in the event of equipment failure.

3.Predictive maintenance and remote fault diagnosis capabilities can help users identify equipment problems before they occur, perform preventive maintenance, and reduce downtime due to failures.

6. Security and Data Protection

1.In order to protect the security of production data and equipment operation, remote monitoring systems usually use encryption protocols (such as TLS, VPN, etc.) to ensure the security of data transmission and prevent unauthorized access.

2.The system can set different user permissions to ensure that only authorized personnel can operate the device remotely.

These RUIJIE Remote Monitoring and Control Functions can not only improve production efficiency, but also significantly reduce the cost of manual operation and improve the level of intelligence and automation of equipment operation.

Choosing the right dewatering screen model requires a comprehensive consideration of multiple factors such as production needs, material characteristics and production scale.

Here are some RUIJIE specific steps and precautions to help you choose the best model and configuration according to your actual situation:

1.Determine The Type Of Material To Be Processed

- Particle Size: The particle size of different materials will affect the selection of screens. Fine-grained materials (e.g., sand, fine sand) require finer screens, while larger particulate materials (e.g. ores) require screens with larger pore sizes.

- Density Of Materials: High-density materials (such as ores, metal powders) have high requirements for the strength of the screen, and it may be necessary to choose a thicker, more wear-resistant screen material.

- Water Content Of Material: The moisture content of the material directly affects the dehydration effect. Materials with high moisture content may require equipment with high vibration frequencies and long screening times to ensure adequate dewatering.

2.Determine Production Needs And Processing Capacity

- Daily Processing Capacity: Select the size and processing capacity of the equipment according to the total amount of materials needed to be processed each day. Usually, the processing capacity of the dewatering screen ranges from tens of tons/hour to several hundred tons/hour, and the specific choice should be based on the overall demand of the production line.

- Continuous Running Time: If the device needs to run continuously for a long time, it is recommended to select the model with strong durability and low maintenance requirements to ensure the stability and durability of the device.

3.Select The Mesh Material And Type

- Polyurethane Screen: suitable for materials requiring high wear resistance, especially suitable for handling fine sand, ore and other abrasion-resistant materials, and long service life.

- Stainless Steel Screen: suitable for corrosive materials, especially in the chemical and food industries, stainless steel has good corrosion resistance.

- Rubber Screen: suitable for large particle materials and occasions requiring high damping effect.

4.Consider Dehydration Efficiency And Accuracy

- Screen Opening Size: the aperture of the screen determines the accuracy of dehydration, the smaller the aperture, the higher the accuracy of dehydration and screening. For applications requiring high accuracy, select a smaller screen aperture.

- Vibration Frequency And Amplitude: High-frequency vibration can improve the dewatering efficiency of the material. According to the characteristics of the material, select the appropriate vibration frequency and amplitude to ensure the uniform distribution and dehydration effect of the material on the screen.

- Screen Surface Inclination Angle: The inclination angle of the screen surface will affect the fluidity and dewatering efficiency of the material, and the appropriate inclination angle design can improve the drainage speed of the material.

5.Consider The Work Environment

- Humidity and Corrosion: If the working environment has high humidity or corrosive substances, it is recommended to choose a waterproof or anti-corrosion device to ensure the durability of the device during long-term work.

- Temperature Conditions: High temperature or low temperature environment will affect the operation stability of the equipment, the selection of high temperature or low temperature resistant materials and components is necessary.

6.Equipment Size And Site Requirements

- Installation Space Limitation: Consider the installation location of the equipment and the available site area, select the appropriate size of the equipment. In the case of a compact production line layout, you can consider customizing the equipment model to suit the space.

- Mobile Or Fixed Installation: Depending on the flexibility of the production line, choose a fixed or mobile dewatering screen. Mobile equipment is suitable for situations that require frequent changes of work locations.

7.Ease Of Maintenance

- Wear Parts Replacement: Choose equipment that is easy to maintain and easy to replace wear parts, especially in the case of high frequency use, rapid replacement of parts such as screens and vibrating motors can reduce downtime and improve production efficiency.

8.After-sales Service

Pay attention to whether the supplier provides equipment commissioning, operation training and maintenance services to ensure that the equipment can be supported in a timely manner during installation and operation.

9.Value For Money and Return On Investment

- Equipment Costs And Operating Costs: Based on the budget, consider the initial cost of the equipment, operating costs (such as energy consumption, maintenance), and production efficiency. High-quality equipment, although the price is slightly higher, has a long service life and low failure rate, which can bring a better return on investment.

- Yield and Revenue: Evaluate whether the processing capacity of the equipment is in line with production goals to ensure that the selected model will provide you with sustained yield growth and economic benefits.

Through these factors, you can choose the type and configuration of the dewatering screen that suits your needs to achieve efficient and stable material handling and dewatering results.

A screening machine is a device used to separate materials into different sizes or grades. It is commonly used in industries such as mining, recycling, and construction to classify and sort materials like sand, gravel, ores, and waste. The main purpose of a screening machine is to ensure that materials are divided based on their size so that only suitable materials move forward in the production or recycling process.

Screening machines come in various forms, such as trommel screens and vibrating dewatering screens. Each type uses a different method to separate materials, but all are designed to improve efficiency, reduce waste, and ensure the right materials are processed.

A screening machine works by using a screen or mesh to separate materials based on their size. Materials are fed into the machine, and the screen filters out smaller particles while larger ones remain. The screening process involves a mechanical movement, either vibrating, rotating, or shaking, that helps materials pass through the screen’s mesh.

In a vibrating screen, the machine uses vibrations to move materials across the screen. Smaller particles fall through the mesh openings, while larger ones stay on top. In a trommel screen, materials are placed into a rotating cylindrical drum. The drum’s movement causes smaller particles to fall through the holes, while larger particles are kept inside the drum.

These machines can be adjusted to suit different materials and processes, ensuring that only the required size of material continues down the production line.