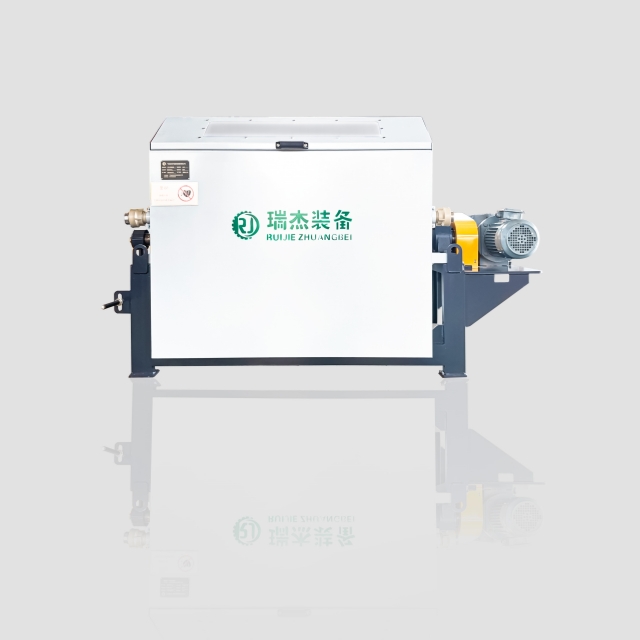

Best Up-suction Magnetic Drum Separators China Supplier

Up-suction Magnetic Drum Separators are mainly used for the separation of various ferrous materials such as scrap steel and incineration bottom ash (IBA).

Up-suction Magnetic Drum Separators Features

1.The middle and upper part of the magnetic shaft adopts ferrite magnetic block, and the magnetic field line is long, which is not easy to demagnetize and not easy to rust.

2.The welding and assembly process of the equipment is rigorous, and the main parts are made of high-quality stainless steel, which is wear-resistant and rust-proof.

3.The rare earth NdFeB magnetic block with high remanence and high coercivity is used as the bottom magnetic source, with strong suction, extremely low demagnetization rate and higher separation purity.

Why Choose RUIJIE Up-suction Magnetic Drum Separators to Solid waste sorting?

RUIJIE is your trusted manufacturer of high-quality counterflow magnetic separators. We offer a comprehensive range of recycling magnetic material sorting machines, unmatched customer support and competitive pricing.

Our commitment to excellence ensures that you receive a reliable scrap metal dismantling, sorting and recycling solution that meets your specific needs and exceeds your expectations.

FAQs

The specific requirements for water quality of up-suction magnetic separators usually include the following aspects:

1.Sediment Content: The sand and particulate matter content in the water quality should be as low as possible. Water with a high sand content can lead to increased wear and tear on the internal components of the equipment and can reduce sorting efficiency. Pre-treated water is recommended to reduce sand content.

2.PH: The pH of the water is also an important factor. The pH of the water should be within the range required by the equipment, usually neutral to slightly alkaline. Extreme acidic or alkaline water quality can cause corrosion or degraded performance of equipment.

3.Dissolved Substances: The concentration of dissolved substances (e.g., salts, chemicals, etc.) should be minimized in the water. High concentrations of dissolved substances can affect the sorting performance or cause corrosion of the equipment.

4.Impurities: Other impurities, such as grease, suspended solids, etc., should be minimized in the water, which may affect the operation and maintenance of the equipment.

In order to ensure the best performance and long life of the Up-suction Magnetic Drum Separators, it is recommended to use water that meets the above requirements, and to carry out water treatment and maintenance according to the recommendations of the equipment manufacturer.

The efficiency of a up-suction magnetic separator does vary depending on the conditions of use. Key factors include:

1.Ore Type: Different types of ore have different magnetic characteristics and physical properties, which will affect the sorting effect of the wet magnetic separator. Some ores may require equipment settings to be adjusted or different sorting methods used to achieve optimal sorting efficiency.

2.Processing Capacity: Changes in processing capacity will affect the load and sorting efficiency of the equipment. Equipment is usually most efficient when it is close to its designed capacity. The processing volume is too high or too low, which may cause the sorting effect to fluctuate

3.Ore Particle Size: The particle size of the ore has a great impact on the sorting efficiency. Ore grains that are too large can cause sorting difficulties, while those that are too small may require finer adjustments. The equipment may need to be adjusted to the actual particle size distribution to optimize the sorting results.

4.Water Quality and Water Flow: Water quality (such as sand content, hardness, etc.) and water flow have a significant impact on the operation of the equipment. Unsuitable water quality or unstable water flow can lead to reduced sorting efficiency.

5.Magnetic Field Strength: The setting of the magnetic field strength is critical to the sorting efficiency. Different ores and processing conditions may require adjustment of the magnetic field strength to achieve the best sorting results.

6.Operating Parameters: The operating parameters of the equipment, such as rotation speed, feeding speed, etc., will also affect the sorting efficiency. It needs to be optimally adapted to the actual operating conditions.

7.Equipment Status: The maintenance and upkeep of the equipment can also affect its efficiency. Regular maintenance and inspection of the equipment can ensure that it is operating at its best, thus maintaining a stable sorting efficiency.

To sum up, in order to ensure the high efficiency of the up-suction magnetic separator under different usage conditions, it is recommended to make necessary equipment adjustments and optimizations according to factors such as ore type, processing capacity, particle size, etc., and maintain good equipment maintenance.