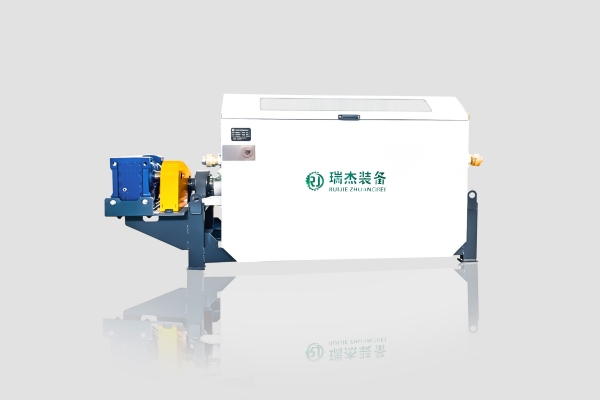

Reliable Wet Drum Magnetic Separators China Manufacturer

Reliable Wet Drum Magnetic Separators are used to screer magnetite, pyrrhotite, roasted ore, ilmenite and other materials with the size nomore than 3mm.

Wet Drum Magnetic Separators Features

1.The shell of the machine is made of high-quality 201 stainless steel, and the surface is sprayed with ceramic paint, which is corrosion-resistant, anti-oxidation, and has a longer service life.

2.The bearing seat is made of cast steel thickening material with extremely high strength and can withstand heavier loads.

3.The unique magnetic field design is adopted, with high magnetic field strength and large gradient, which is more conducive to the recovery of low-grade ore.

Why Choose RUIJIE Wet Drum Magnetic Separators for Incineration Bottom Ash, Magnetic Mineral Industry?

With more than 15 years of experience in the wet magnetic separation industry, RUIJIE is a trusted supplier of high-quality wet magnetic separators and countercurrent magnetic separators.

We offer competitive prices, fast delivery services, and customized solutions to meet your specific needs.

FAQs

Wet magnetic separator operation can have a number of negative environmental impacts, including noise, wastewater, exhaust gases, and solid waste. To minimize these effects, the following measures can be taken:

1.Noise Control:

- Sound Insulation Measures: Install sound barriers or use sound insulation materials around the equipment to reduce noise transmission.

- Equipment Maintenance: regularly check and maintain the equipment to ensure its normal operation and reduce the noise caused by failure.

2.Wastewater Management:

- Wastewater Treatment: Ensure that wastewater is properly treated and meets discharge standards to prevent contamination of water sources.

- Reuse System: The treated wastewater is returned to equipment cleaning or other processes, reducing the need for fresh water.

3.Solid Waste Management:

- Solid Waste Treatment: Regular cleaning and treatment of solid waste generated by equipment, sorting and recycling or appropriate disposal.

- Waste Reduction: Reduce solid waste generation by optimizing production processes.

4.Energy Consumption:

- Energy-saving Technology: The use of energy-saving technology and equipment to reduce energy consumption.

- Optimize Operation: Improve energy efficiency by improving operation processes.

5.Environmental Monitoring:

- Regular Inspection: Environmental monitoring is carried out to assess the impact of equipment on the surrounding environment.

- Adjust Operation: Adjust operation and maintenance based on monitoring results to ensure that the impact of equipment on the environment is minimized.

4.Comply with Environmental Protection Regulations:

- Compliance: Ensure equipment and operations comply with local environmental regulations and standards, following industry best practices.

Through these measures, the negative impact of equipment operation on the environment can be effectively minimized, and the environmental performance of the equipment can be improved.

Wet magnetic separators can generate wastewater during operation, which needs to be properly treated to meet environmental standards. The steps of wastewater treatment typically include the following:

1.Primary Sedimentation:

- Filtration: Use coarse strainers or screens to remove large particulate impurities from wastewater.

- Precipitation: Through the sedimentation tank to let the larger particles settle, reduce the solid load of wastewater.

2.Intermediate Processing:

- Flocculation and Sedimentation: Add flocculant to aggregate suspended particles to form flocculent, further sedimentation.

- Air Flotation: The use of bubbles to float suspended particles and remove them.

3.Advanced Processing:

- Biological Treatment: If the wastewater contains organic matter, it may be necessary to use biological treatment methods (such as activated sludge process) to remove organic contaminants.

- Chemical Treatment: In some cases, it may be necessary to use chemicals to remove specific contaminants, such as heavy metals.

4.Water Quality Reuse:

- Reuse System: The treated water can be recycled for equipment cleaning or other processes to reduce the need for fresh water.

5.Waste Water Discharge:

- Discharge Standards: Ensure that the treated wastewater complies with local environmental regulations and discharge standards, and is safely discharged or further treated.

Effective wastewater treatment not only reduces environmental impact, but also reduces operating costs and improves the overall sustainability of your equipment.