High Intesity Suspended Permanent Magnetic Separator China Manufacturer

RUIJIE is your trusted manufacturer and supplier of suspended permanent magnetic separators. These machines use a permanent magnet, which generates a strong magnetic field to attract and trap ferrous contaminants from various materials. There is no need for motors, eliminating dependence on the power supply. This reduces maintenance requirements and ensures reliable, cost-effective operation.

Features of Our Permanent Mangetic Separator

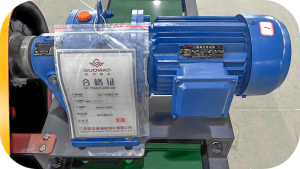

- The copper core motor is adopted, the energy consumption is low, the speed and torque can be maintained high, and the working state can be maintained relatively stable during use.

- Using high-performance permanent magnet material, the magnetic circuit is balanced, and the adsorption force is strong.

- The main components of the equipment are made of stainless material, and the welding and assembly process is rigorous.

- The magnetic group is waterproof and the core section is rust resistant and durable.

RUIJIE Suspended Permanent Magnetic Separator Series

RUIJIE provides reliable suspended permanent magnetic wet separation solutions designed to match your specific requirements. Each unit is carefully engineered to fit your operational needs, ensuring maximum efficiency and reliability.

Additionally, as OEM manufacturer, we also offer logo printing, allowing you to showcase your brand directly on the equipment. This not only enhances brand recognition but also reinforces your professional image in the industry.

Benefits of RUIJIE’s Permanent Magnetic Separators

- The permanent magnet mineral separator uses a copper core motor. This reduces energy consumption while maintaining high speed and torque. It ensures stable performance during long hours of use, which helps minimize downtime and improve efficiency.

- The separator uses high-performance permanent magnet materials. The magnetic circuit is balanced. This creates a strong and reliable adsorption force, improving separation results.

- The main components are made from high-quality stainless steel. This makes the machine strong and durable. It is resistant to corrosion and can handle tough working conditions. The welding and assembly are precise, showing RUIJIE’s commitment to quality. Every part fits perfectly, ensuring the best performance.

- The magnet is waterproof and rust-resistant. These features make the separator long-lasting, even in harsh environments. They reduce the need for frequent maintenance and increase reliability.

Why Choose RUIJIE For High Intensity Permanent Magnetic Iron Separators?

Looking for reliable permanent magnetic separator manufacturer? RUIJIE supplies high-quality and high intensity magnetic separation solutions . We offer a comprehensive range of sorting machines for recycling magnetic materials. Our customer support is exceptional, and our pricing is competitive from direct manufacturer. We are committed to excellence, ensuring that you receive a reliable scrap metal sorting and recycling solution that meets your specific needs and exceeds your expectations.

Suspended Permanent Magnetic Separator In Detail

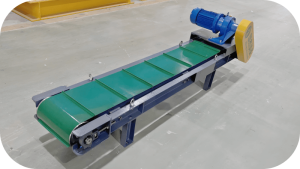

The key components of the RUIJIE‘s permanent magnetic separator are designed for durability, ensuring the efficiency and reliability of our machines:

-

Chain Wheel: The transmission system uses a 16A sprocket structure, ensuring stable operation with minimal need for maintenance.

-

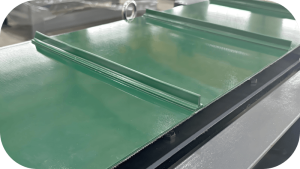

Belt: Made from PU material, the belt is durable, resistant to deformation, and offers excellent wear resistance.

-

Magnetic Box: The magnets are covered with a 2mm thick 201 stainless steel plate, offering anti-corrosion and rust protection. Sealants are applied to all joints for waterproofing.

-

Motor: The motor is from a well-known domestic brand, with a power rating of 1.5KW, ensuring stable and long-lasting performance.

-

Rollers: Both the main and driven rollers are made from 5mm thick 304 stainless steel. The rollers have high resistance to magnetism, corrosion, and rust, ensuring they don’t attract iron materials.

-

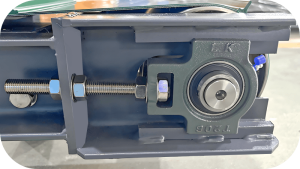

Bearings: Bearings are easy to replace and provide simple belt tension adjustment. The main and driven bearings are from international brands, ensuring stable operation and a long service life.

-

Frame: Constructed from 201 stainless steel, the frame is resistant to deformation, rust, and magnetism, which helps reduce the adsorption of iron materials.

Permanet Magnetic Separation Applications

Permanent magnetic separators are essential in metal recycling and resource recovery. They efficiently extract valuable ferrous and non-ferrous metals from mixed materials, ensuring that reusable metals are reclaimed for remanufacturing. These separators are widely used in scrap metal recycling, e-waste processing, and automotive recycling to recover steel, iron, and other magnetic metals.

They also play a crucial role in mining operations, separating valuable ores from unwanted materials. Permanent magnetic separators optimize resource utilization, reduce waste, and support sustainable production.

FAQs

1.Can The Equipment Effectively Remove Ferrous Impurities From The Material?

2.For Different Types Of Materials, Is The Iron Removal Effect Stable And Reliable?

1. The Core Factor Of Iron Removal Effect

Magnetic Field Strength: The permanent magnetic separator the ferrous impurities in the material through the action of the magnetic field. The strength of the magnetic field is a key factor in determining the effectiveness of iron removal. The high-intensity magnetic field can effectively capture small or weak ferrous impurities to ensure the effect of iron removal.

- Equipment Design: The design of the permanent magnetic iron separator, including the tilt angle of the shaker, the vibration frequency, the magnetic field coverage, etc., will affect the iron removal effect. The optimally designed equipment ensures that the material is adequately processed as it passes through the magnetic field, maximizing the removal of ferrous impurities.

2. Iron Removal Effect Of Different Materials

- Ore Materials: For iron ore, copper ore and other minerals, the Suspended Permanent Magnetic Separator can effectively remove iron impurities and ensure the purity of the ore. The iron removal effect is usually very stable, especially when dealing with ore with uniform particle size.

- Sand and Gravel Materials: In sand and gravel processing, the Permanent Suspended Magnetic Separator can remove the iron impurities in the sand and gravel, and avoid the wear and tear of these impurities on the subsequent processing equipment (such as crushers and mills). For dry or moderately humid sand and gravel materials, the iron removal effect is also stable.

- Coal Materials: In coal processing, the permanent magnetic overband separator can effectively remove ferrous impurities from coal, protect subsequent equipment and improve combustion efficiency. Even for wet coal or smaller coal material sizes, the equipment provides reliable iron removal.

- Powdered and Fine-grained Materials: For powdery or fine-grained materials with smaller particle sizes, the permanent magnetic separator can achieve effective iron removal by appropriately adjusting the vibration frequency and magnetic field strength. The equipment can handle materials from coarse to fine grains and is highly adaptable.

3. Stability Of Permanent Magnetic Separator Effect

- Adaptable To A Wide Range Of Materials: The iron removal effect of thepermanent magnetic separator is usually stable when handling different types of materials. Whether it’s ore, sand, coal or other fine-grained materials, the equipment provides efficient and reliable iron removal.

- Environmental Factors: The effectiveness of the equipment in removing iron may be affected by environmental factors such as humidity, temperature, and material flowability. However, most permanent magnetic separators are designed with these factors in mind, and the stability of the iron removal effect is guaranteed by adjusting the equipment parameters such as the strength of the magnetic field.

4. Iron Removal Efficiency

- Efficient iron removal: permanent magnetic separators are usually able to remove iron from large quantities of material in a short period of time. The processing efficiency of the equipment depends on the flow rate of the material, the strength of the magnetic field and the degree to which the design of the equipment is optimized. For the continuous processing of large quantities of material, the RUIJIR permanent magnetic separatoroffers an efficient solution for iron removal.

- Iron Impurity Recovery: The design of the equipment ensures the recovery rate of high-iron impurities, that is, the equipment is able to separate most of the ferrous impurities from the material, thereby improving the purity of the material. The recovery rate of impurities in high-speed rail means that the equipment is effective in removing iron and can meet the production needs of high quality requirements

5. The influence of operation and maintenance on the effect of iron removal

- Regular Maintenance: Regular maintenance of the permanent magnetic separator, to maintain the cleanliness of the equipment and the strength of the magnetic field, is an important factor to ensure the effect of iron removal. The accumulated iron impurities should be cleaned up in time to prevent affecting the magnetic field strength and vibration effect of the equipment.

- Operator Experience: Skilled operators are able to adjust equipment parameters according to the characteristics of the material and optimize the effect of iron removal. Therefore, the training and experience of the operator also have a certain impact on the iron removal effect of the equipment.

Permanent magnetic separators typically provide stable and reliable iron removal when handling different types of materials. Its efficient magnetic field design, optimized equipment structure and diverse adaptability enable it to efficiently remove ferrous impurities, especially in ore, sand, coal and powder material handling. With proper operation and regular maintenance, users can be sure that the equipment will maintain excellent iron removal results over the long term.

1.Is The Installation Of A Permanent magnetic Separator Complicated?

2.Does The Operation Require Specialized Skills?

3.Does The Supplier Provide Detailed Operating Instructions Ar Training Services?

Here Are The Details About The Installation And Operation Of The Equipment:

1. Ease of Installation

- Equipment Layout and Installation Requirements: The installation process of the permanent magnetic separator is usually not complicated, and the equipment is designed to take into account the actual needs of the industrial site. The standard equipment is equipped with easy-to-install fixing brackets and attachment parts, and the user only needs to follow the steps in the installation manual.

- Foundation Preparation: Before installation, users need to ensure that the foundation preparation of the site is in place, including the stability of the foundation, the configuration of the power supply, the planning of the material transportation path, etc. These preparations generally do not require complex construction.

- Installation Time: For standard models of permanent magnetic separator, the installation time is usually shorter, generally completed within 1-3 days. Larger or customized equipment may take more time, but the vendor will often provide detailed installation guidance and support.

2. Ease Of Operation

- Intuitive Operator Interface: Modern permanent magnetic separator are often equipped with an intuitive operator interface that allows the user to easily adjust the operating parameters of the device, such as vibration frequency, magnetic field strength, etc., via a push-button control panel or touch screen. The operator interface is designed to reduce the complexity of operation and enable users to get started quickly.

- 3. Whether Specialized Skills Are Required

Basic Operating Skills: For day-to-day operations, permanent magnetic separator do not require highly specialized skills on the part of the operator. With simple training, most operators are able to master the basic operating procedures of the equipment. - Maintenance & Troubleshooting: Although basic operations are not complex, some maintenance tasks and troubleshooting may require some expertise. Vendors often cover these in training to ensure that operators are able to handle common issues.

- Vendor Support: For more complex operations or troubleshooting, vendors often provide remote support or on-site service to help users resolve issues.

4. Operating Instructions And Training Services Provided By The Supplier

- Operation Instruction Manual: RUIJIE supplier will provide detailed operation instruction manuals with the equipment, covering installation steps, operation procedures, maintenance guidelines, and troubleshooting methods. These manuals often contain illustrated instructions to help users intuitively understand each step.

- On-site Installation Guidance: After the equipment is delivered, we will send technicians to the user’s site to provide installation guidance to ensure that the equipment is properly installed and put into operation.

- Operation Training: The supplier provides operation training services, including basic operation, parameter setting, daily maintenance and troubleshooting of equipment. Training can be conducted on-site at the user site or completed through an online platform.

- Remote Support: After the training, the RUIJIE supplier will also provide continuous remote support services. Users can contact suppliers by phone, email, or online platforms for operational advice or technical assistance.

The installation and operation of the permanent magnetic separator is designed to be simple and easy. The installation process is usually uncomplicated, the operator interface is intuitive, and the operator can master the basic operation with simple training.

While some maintenance tasks may require some specialized skills, we provide comprehensive operating instructions and training services to ensure that users are able to use and maintain the equipment effectively.

Our support services also provide users with an extra layer of reassurance that any issues with the operation of the equipment are resolved in a timely manner.

A permanent magnet is a magnet that keeps its magnetic properties without needing electricity. It is made from special materials like neodymium, ferrite, or samarium cobalt, which naturally produce a strong magnetic field. Unlike electromagnets, which require a power source to generate magnetism, permanent magnets work all the time.

They are used in many products, such as motors, speakers, and magnetic separators. Since they do not need electricity, they are reliable and energy-efficient. However, they can lose strength over time due to heat, physical damage, or exposure to strong magnetic fields.

Electromagnets are usually stronger than permanent magnets because their strength depends on the amount of electric current flowing through them. By increasing the current or using more wire coils, an electromagnet can produce a much stronger magnetic field than a permanent magnet.

This is why electromagnets are used in powerful applications like industrial lifting, maglev trains, and large generators. However, permanent magnets are still strong and efficient for many uses, such as in electric motors, magnetic separators, and sensors. The choice between them depends on the application’s need for power, control, and energy efficiency.