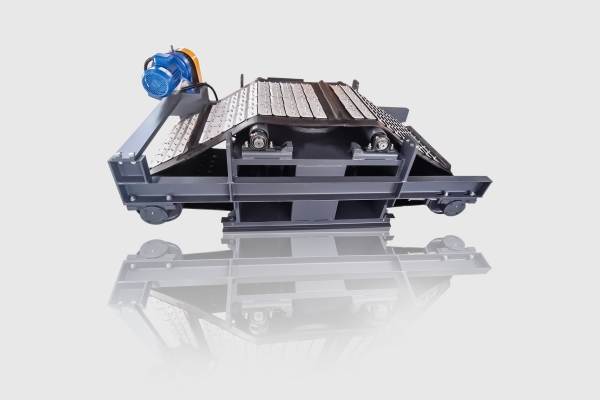

Your Best Electromagnetic Overband Separator Manufacturer From China

Electromagnetic Overband Separator is specially used in scrap metal recycling and sorting, incineration bottom ash (IBA) sorting and other metal recycling fields

Electromagnetic Overband Separator Features

1.The solenoid coil has high remanence and high coercivity, and the magnetic force can be adjusted through the electric control cabinet.

2.The main parts of the equipment are made of stainless steel, and the welding and assembly processes are rigorous.

3.The unique design of the armored belt can effectively prevent the damage of sharp ferromagnetic debris to the belt, and the operation is more stable and durable.

4.The magnetic group is waterproof, the core is rust-proof and durable, and the service life becomes longer.

Why Choose RUIJIE Electromagnetic Overband Separator to Iron removal?

RUIJIE is a trustworthy supplier of strict quality Electromagnetic Overband Separator products. We offer competitive prices, fast lead times, and customized magnetic separation solutions to meet your specific needs.

Our expertise in drum magnetic separators, suspended electromagnetic separators, and non-ferrous metal sorting machines ensures optimal performance and reliability for your recycling line.

FAQs

The Maintenance And Upkeep Requirements For The Equipment are As Follows:

1.Regular Inspection:

- Magnetic Field Strength: Measure the magnetic field strength of the equipment regularly to ensure that it is within the design range. If a drop in magnetic field strength is found, it may need to be adjusted or repaired.

- Electrical System: Check electrical wiring and control systems to ensure there is no loose, damaged or short circuit.

2.Equipment Cleaning:

- Magnet Surface: Regularly clean the surface of the magnet to remove the attached iron impurities to maintain the strength of the magnetic field and the effectiveness of the equipment. Especially after high-load work, it is necessary to focus on cleaning.

- Environment Around The Device: Keep the area around the device clean to prevent dust and impurities from accumulating and affecting the device running.

3.Lubrication:

- Moving Parts: Regularly check and lubricate moving parts of the equipment, such as bearings and transmissions. Use appropriate lubricating oil or grease to ensure smooth running of components and reduce wear and tear.

4.Check The Fasteners:

- Bolts And Nuts: Check whether the bolts and nuts of the device are loose and ensure that all fasteners are secure. Loose fasteners may cause unstable operation or abnormal noise.

5.Check Insulation And Cables:

- Cable Insulation: Periodically check the insulation status of the cable to ensure that the insulation layer is not aging or damaged, to avoid electrical short circuit or security risks.

- Cable Connection: Ensure that all cables are securely connected to avoid electrical failure or equipment shutdown due to loosening.

6.Equipment Operation Record:

- Record Logs: Maintain device running logs, recording the maintenance, overhaul, and fault information. These logs help analyze device usage and predict maintenance requirements.

7.Regular Professional Maintenance:

- Comprehensive Inspection: According to the use of the equipment and operating environment, arrange professional personnel to carry out a comprehensive overhaul of the equipment regularly, especially after a long period of operation or failure, to ensure the stability and safety of the equipment.

8.Machine Fault Handling:

- Fault Diagnosis: When the equipment fails, the fault diagnosis is carried out immediately to identify the root cause of the problem and deal with it in time to reduce the downtime of the equipment.

- Technical Support: If you need more complex maintenance or troubleshooting, contact the equipment supplier or technical support personnel for help.

9.Operator Training:

- Training and Education: Provide operators with equipment operation and maintenance training to ensure that they understand the proper use of equipment and basic maintenance steps to reduce failures caused by improper operation.

By performing these maintenance and maintenance measures, you can ensure the efficient and stable operation of the magnet separator and extend the service life of the equipment

The applicability of the Electromagnetic Overband Separator will indeed vary depending on the characteristics of the material. Here are some of the key factors that determine if a device is suitable for a particular material:

1. Type Of Material

- Metal Content: The magnetic field strength of the device needs to be high enough to effectively separate materials containing iron impurities. For materials with a higher metal content, a stronger magnetic field is usually required.

- Non-magnetic Materials: If the material itself does not contain iron or other magnetic metals, the magnet separator may not be suitable.

2. Particle Size Of Materials

- Fine Grained Materials: For smaller grained materials, such as powder or fine sand, higher magnetic field strength and a more sophisticated design may be required to ensure that tiny iron impurities are captured.

- Coarse-grained Materials: Large-grained materials are generally easier to handle with electromagnetic hangers, but it is necessary to ensure that the equipment is designed to handle the size and shape of the material.

3.The Humidity Of The Material

- Dry Materials: Most of the electromagnetic hanging iron separator in the treatment of dry materials when the best effect, the magnetic field can directly act on the iron impurities, the separation effect is better.

- Wet or Viscous Materials: For materials with high humidity or strong viscosity, iron impurities may adhere to the material, reducing the separation effect. In this case, you need to select the equipment suitable for wet material processing, or take pretreatment measures.

4.Fluidity Of Materials

- Free-flowing Materials: If the material has good mobility, the magnetic separation effect is usually better, because the material can evenly pass through the magnetic field area.

- Poor Flow Materials: For poor flow materials, specially designed equipment or material pretreatment measures may be required to ensure that the material can smoothly pass through the magnetic field area to achieve the desired separation effect.

5.Conductivity And Magnetism Of The Material

- Highly Conductive Materials: Materials with high conductivity may produce eddy currents in the magnetic field, affecting the effect of iron removal. You need to consider whether you need to adjust the magnetic field design or frequency.

- Weak Magnetic Material: If the material itself is weak magnetic, a higher magnetic field strength is required to effectively separate the iron impurities in it.

6.Material Flow

- High-volume Material Handling: If high-volume material needs to be processed, ensure that the equipment is designed to maintain iron removal at high flow rates.

In summary, the suitability of an electromagnetic separator depends on the characteristics of the material, including particle size, humidity, fluidity, conductivity, magnetism, and industry application. By combining these factors, it is possible to determine whether the equipment is suitable for a specific material and ensure the best possible iron removal.