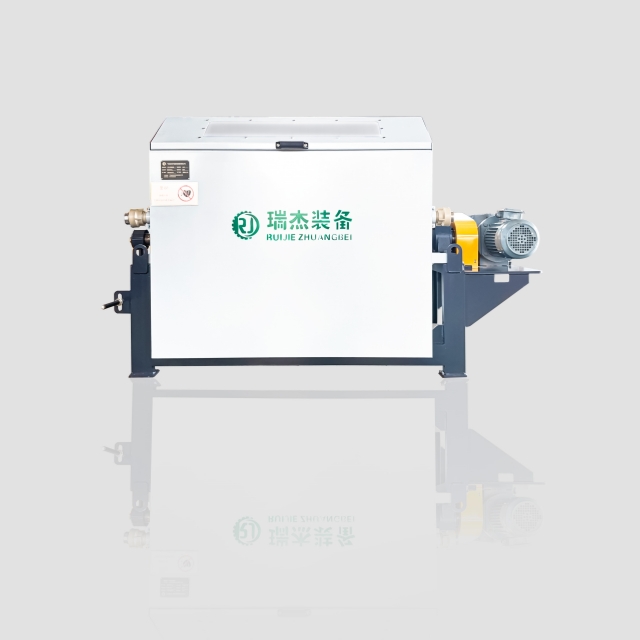

Reliable Magnetic Separation Equipment China Manufacturer

Looking for reliable manufacturers or suppliers of magnetic separation equipment? RUIJIE is your trusted partner based in China, specializing in high-quality magnetic separators for metal sorting. Our range of products are designed for various industries, including metal recycling, mining, building materials, slag treatment and environmental protection.

Features of Our Magnetic Separation Equipment

- Organic ceramic paint wraps the fuselage with better adhesion and higher corrosion resistance.

- The centralized junction box centralizes the management of all wiring harnesses of the machine, and the safety performance is higher.

- The magnetic roller uses aviation material wrapping technology to isolate the air and completely eliminate oxidation and corrosion.

- The magnet material was produced by the best supplier in China , to ensure that the demagnetization rate would not be more than 3% in 15 years.

RUIJIE Magnetic Separation Equipment Series

We offer a comprehensive range of magnetic separator machine tailored to diverse needs. Our product lineup includes:

- Eddy Current Separator: Ideal for separating non-ferrous metals from other materials.

- Wet Drum Magnetic Separators: Effective in separating magnetic particles in slurry form.

- Up-suction Magnetic Drum Separators: Designed for efficient separation of larger ferromagnetic materials.

- Electromagnetic Overband Suspended Separator: Suitable for overhead separation in conveyor systems.

- Permanent Magnetic Suspended Separator: A reliable and cost-effective solution for many applications.

Why Choose RUIJIE?

- Fast Global Shipping – We ensure quick and reliable delivery to any location.

- Affordable Pricing – As a direct manufacturer, we offer competitive prices that save you money.

- Excellent Service – Our team is always ready to assist you with quick responses and friendly service.

- Flexible MOQ – With just 1 unit minimum order, we cater to businesses of any size.

- Custom OEM Solutions – We provide tailored products to meet your specific requirements.

Request a Quote for Reliable Magnetic Separation Solutions from RUIJIE!

RUIJIE is your trusted manufacturer & supplier of custom magnetic separation equipment and other sorting solutions. We offer a wide range of magnetic separators for various applications.

We are committed to providing reliable scrap metal recycling solutions for industries such as mining, incineration bottom ash, solid waste separation, and more, ensuring that we meet your specific requirements.

Common Applications of Magnetic Separation Device

Benefits of Magnetic Separation Equipment

-

Efficient Separation

Magnetic separation effectively isolates magnetic materials from non-magnetic ones, ensuring high efficiency in processes like mining and recycling. -

Energy and Cost Savings

Permanent magnetic separators require no electricity to operate, making them more energy-efficient and reducing operational costs compared to electromagnetic systems. -

Versatility

Magnetic separators are adaptable for both dry and wet processing, offering flexibility for a wide range of applications across different industries. -

Low Maintenance Requirements

These separators require minimal maintenance, reducing downtime and repair costs while ensuring continuous operation. -

Environmental Sustainability

Magnetic separation reduces the need for chemical reagents used in other methods, aligning with eco-friendly practices and supporting sustainability goals.

Applications of Magnetic Separator Machines

Our magnetic separation equipment is a key solution for industries focused on renewable resources and material recycling. Designed to effectively separate magnetic materials from non-magnetic materials, it enables businesses to recover valuable metals like steel, copper, aluminum, and other ferrous and non-ferrous materials. This process helps increase material purity and optimizes recycling operations.

Magnetic separation is widely used in various industries for separating valuable metals from waste and recyclable materials. Here are some key applications:

- Electronic Waste Recycling

Magnetic separation is highly effective in recovering precious metals like copper and aluminum from e-waste, helping to reduce environmental pollution and improve resource efficiency. - Construction and Demolition Waste Recycling

During the recycling of construction debris, magnetic separators help extract metals like steel and iron from mixed materials, ensuring that only clean, reusable metals are returned to the supply chain. - Automobile Recycling

In vehicle dismantling processes, our magnetic separation systems can remove iron and aluminum components from old car parts, improving the efficiency of automotive recycling and minimizing waste. - Mining and Mineral Processing

Magnetic separators are essential in the mining industry to remove unwanted magnetic materials from mineral ores, improving the quality of the processed materials and supporting sustainable mining practices.

Frequently Asked Questions about Magnetic Separation Equipment

1. Which material can be used for magnetic separation?

Magnetic separation is most commonly used to separate ferromagnetic materials, such as iron, nickel, and cobalt, from non-magnetic materials like plastics, wood, and ceramics.

It’s ideal for processing materials in recycling and mining industries, helping to remove magnetic impurities from ores, or separating metals from other waste. Magnetic materials have magnetic properties, making them easy to attract and remove using magnetic fields.

2. What device is used to separate magnetic material from junk?

A magnetic separator is the device typically used to separate magnetic materials from non-magnetic waste. This device works by generating a magnetic field that attracts magnetic metals, like iron, from a mixture of materials.

Magnetic separator machines come in different forms, such as wet drum separators, eddy current separator, suspended separators, permanent magnetic separators, or electromagnetic separators. They are essential in industries like recycling, mining, and manufacturing, ensuring that magnetic materials are efficiently removed from unwanted waste.

3. Can you use magnetic separation for all metals?

No, magnetic separation cannot be used for all metals. It is only effective for ferromagnetic metals such as iron, nickel, and cobalt. These metals are strongly attracted to magnets.

However, non-ferromagnetic metals like aluminum, copper, and brass are not attracted to magnets and cannot be separated using this method. For non-magnetic metals, other separation techniques such as air classification or flotation may be used.

4. Which metal cannot be separated by magnetic separation?

Aluminum is one of the metals that cannot be separated by magnetic separation. Unlike ferromagnetic metals, aluminum is non-magnetic, meaning it does not respond to magnetic fields.

Other metals like copper, brass, gold, and silver also fall under the non-magnetic category and require different techniques for separation.

FAQs

The lifespan of a permanent magnetic separator typically ranges from 10 to 15 years or more, depending on the equipment’s quality, the operating environment, and the maintenance practices. Regular maintenance and timely inspections are essential to extend its service life.

Choosing a reputable supplier like RUIJIE, known for producing durable and high-quality machines can ensure a longer lifespan.

Our magnetic materials will not demagnetization more than 3% in 15 years.

Key materials include high-quality magnetic materials (such as rare earth magnets or ferrite magnets), durable metals for the frame and structure (often steel or stainless steel), and wear-resistant materials for components that come into direct contact with the processed materials.

RUIJIE only use quality materials to ensure long-term reliability and durability.

The core principle involves using a magnetic force to attract and separate ferromagnetic materials from non-magnetic ones.

The materials are typically passed over or through a magnetic field generated by a magnetic drum or belt. Ferrous materials are drawn to the magnet, while non-ferrous materials continue their course.

RUIJIE provides a variety of magnetic separation techniques to ensure optimal separation.