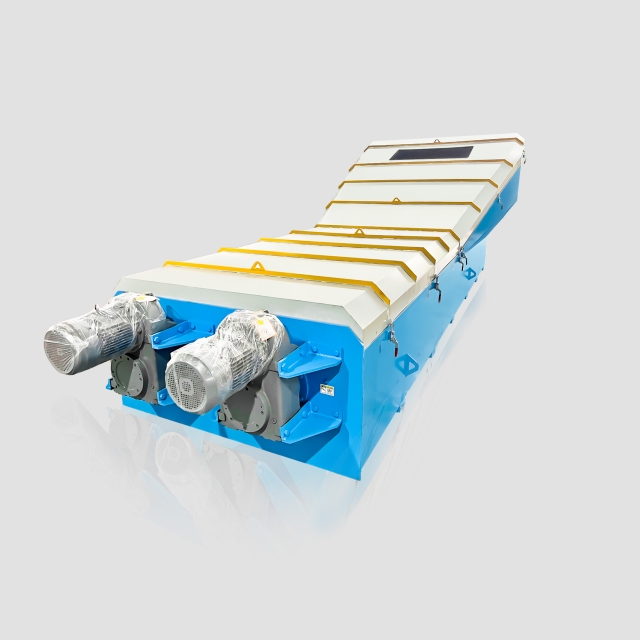

Rugged and Durable Screw Sand Washing Machine China Factory

Screw Sand Washing Machine utilizes a spiral screw to stir and remove impurities from the sand, ensuring effective cleaning and dewatering.

Screw Sand Washing Machine Features

1. Sealing drive bearing device, avoid the damage caused by water, sand, and pollutants.

2. High-yield cleaning, making finished stone more cleaner.

3. Large one-time processing capacity, adapt to large-scale and high-capacity operation.

4. Q355B steel plate main body, higher strength, stronger wear-resistance, corrosion resistance.

5. Polyurethane rubber plate spiral blades, more wear-resistant, longer service life.

Why Choose RUIJIE Screw Sand Washing Machine for Sand and stone field, mining and other industries?

Through the RUIJIE spiral sand washing machine, the precise cleaning of sand and gravel is realized, ensuring that every batch of products produced meets the highest standards. Get a free quote now and enjoy our professional equipment support!

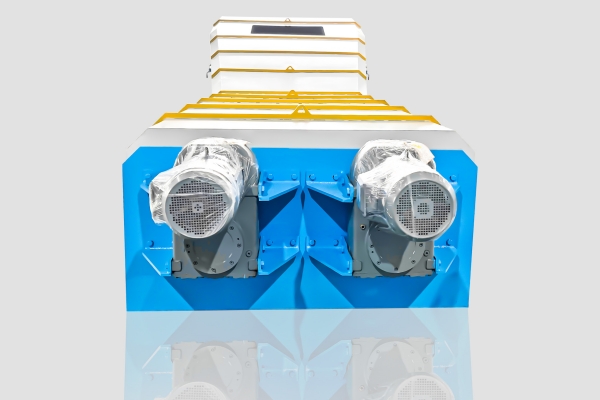

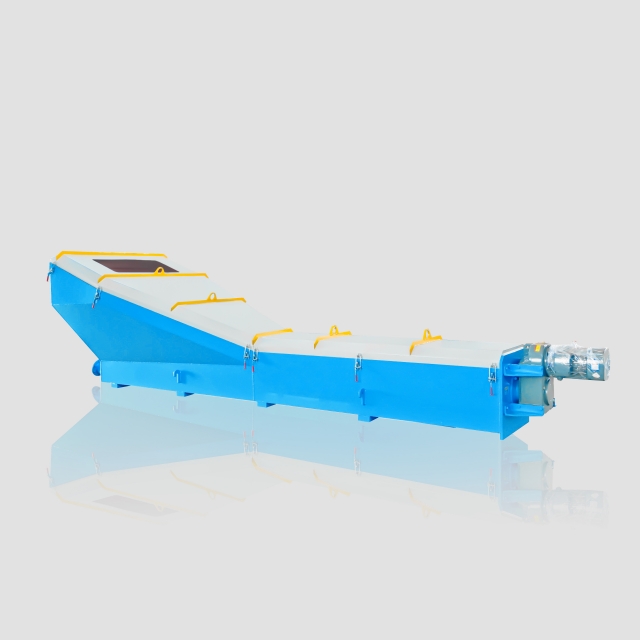

Components of Spiral Sand Washer

The components of spiral sand washing machine include reducer, bearing seat, polyurethane rubber plate, scraping board.

The benefit of using polyurethane rubber plate

- High Wear Resistance.

- High Strength and Elasticity.

- Corrosion Resistance and Chemical Stability.

- Aging and Weather Resistance.

- Good Sealing and Noise Reduction.

- Improving Screening Efficiency.

- Reduces Energy Consumption and Maintenance Costs.

FAQs

There are some common faults or problems that the spiral sand washer may encounter during use.

Understanding these issues and addressing them in a timely manner can effectively reduce downtime and extend the life of your equipment.

Here are some common failures along with their possible causes and solutions:

1.Abnormal Vibration Of The Equipment:

- Causes: The foundation of the equipment is not stable, the spiral shaft or blades are seriously worn, the bearing is damaged, the transmission system is loose, etc.

- Solution: Check whether the foundation of the equipment is stable and tighten all bolts; Check the wear of the spiral shaft and blades and replace them if necessary; Check the bearing for damage or lubrication.

2.The Sand Washing Effect Is Not Good

- Causes: Excessive or uneven feeding, worn spiral blades, inappropriate spiral speed, insufficient water flow or water quality problems.

- Solution: Adjust the feeding speed to ensure uniform feeding; inspect and replace worn spiral blades; Adjust the spiral speed and water flow rate to ensure that the water quality in the sand washing process meets the requirements.

3.Device Blockage:

- Causes: The processed material contains too many large particles or debris, the gap between the spiral blades and the tank is too small, and the feeding speed is too fast.

- Solution: Clear the blockage, check and clean the inlet; Properly adjust the gap between the blade and the trough; Adjust the feed speed to avoid feeding too fast.

4.Bearing Overheating:

- Causes: Lack of lubrication of bearings, poor or insufficient lubricating oil, damaged bearings, excessive equipment load.

- Solution: Regularly check and add the appropriate amount of high-quality lubricating oil; Check the bearings for wear or damage and replace them if necessary; Avoid overloading the equipment for long periods of time.

5.Motor Failure Or Overload:

- Causes: insufficient motor power, unstable power supply voltage, overloaded equipment, and excessive resistance of the transmission system.

- Solution: Check the power and power supply of the motor to ensure stable power supply; Avoid the equipment to run under overload conditions for a long time; Check the drivetrain to make sure it’s running smoothly.

6.Excessive Noise:

- Causes: Improper installation of the equipment, severe wear of the helical shaft or blades, damaged or lack of lubrication of the bearings, loose transmission system.

- Solution: Check whether the device is installed firmly, adjust or reinstall; Check the wear of the spiral shaft and blades, and replace them if necessary; Check the lubrication status of the bearing, add lubricating oil or replace the bearing; Tighten the components of the drivetrain.

7.Slippage or Breakage of Transmission Belt:

- Causes: loose or aging transmission belt, excessive equipment load, poor alignment between transmission belt and pulley.

- Solution: Adjust the tightness of the transmission belt to ensure that the transmission belt and the pulley are well aligned; Regularly check the wear and tear of the transmission belt, and replace the new transmission belt if necessary; Avoid overloading the equipment.

8.Insufficient or Unstable Water Flow:

- Causes: Faulty water supply system, pump problems, unstable water source, or clogged pipes.

- Solution: Check the working condition of the water supply system and pumps, and clean the blockages in the pipes; Ensure that the water source is sufficient and stable, and replace the pump or adjust the water supply pipe if necessary.

9.The Water Content Of The Finished Sand Is Too High:

- Causes: insufficient dewatering link, high mud content of the material, and inappropriate angle of spiral blades.

- Solution: Check the working condition of the dehydration equipment, adjust or replace it if necessary; Ensure that the material is fully pretreated to reduce the sludge content; Adjust the angle of the spiral blades to optimize dewatering.

The spiral sand washing machine may encounter a variety of faults during use, including equipment vibration, poor sand washing effect, overheating of bearings, motor failure, excessive noise, etc.

Regular maintenance and inspection of the equipment and timely handling of the problems found can effectively reduce the frequency of failures and ensure the long-term stable operation of the equipment.

If you encounter complex or difficult-to-solve faults, it is recommended to seek help from RUIJIE professional technicians.

The wearing parts of the spiral sand washing machine mainly include the following categories, and their replacement frequency and cost vary depending on the use, material nature and equipment model. Here are some common consumables and their related information:

1.Helical Blade:

Spiral blades are parts that are in direct contact with sand and soil, and will be subject to wear and tear after long-term use.

- Replacement Frequency: It depends on the hardness of the material and the frequency of equipment use. In general, it may need to be replaced every six months to a year. If the material being processed is harder or has a higher sludge content, wear will accelerate and may need to be inspected and replaced more frequently.

- Replacement Cost: The replacement cost of spiral blades depends on the equipment model and material, and usually ranges from a few hundred to several thousand yuan.

2.Bearing:

The bearing is the key component that supports the rotation of the helical shaft, and long-term high-load operation can easily lead to wear or failure.

- Replacement Frequency: Usually inspected annually, may need to be replaced every 1-2 years depending on usage. If it is not lubricated properly or is overloaded, its service life may be shortened.

- Replacement Cost: The price of bearings varies according to the model and quality, generally between a few hundred and thousands of yuan.

3.Sealing Element:

Seals are used to prevent mud, moisture, etc. from entering the inside of the equipment, and will deteriorate or wear out after long-term use.

- Replacement Frequency: It usually needs to be inspected and replaced once a year, depending on the environment and frequency of the equipment.

- Replacement Cost: The price of seals is low, generally between tens and hundreds of yuan.

4.Transmission Belts and Gears:

Transmission belts and gears are important components that connect the motor and the screw shaft, which are responsible for power transmission and will loosen, wear or break after long-term use.

- Replacement Frequency: Usually check every 1-2 years, and decide whether to replace or not according to the wear and tear. Equipment under heavy use or under heavy load may need to be replaced more frequently.

- Replacement Cost: The price of transmission belts and gears is generally between a few hundred and thousands of yuan.

5.Motor:

The motor is the power source of the spiral sand washer, and although it is not a typical wearing part, it can also fail in the case of high-load work and improper maintenance.

- Replacement Frequency: The life of the motor is generally longer, usually 5-10 years, but it needs to be checked and maintained regularly to prolong the service life.

- Replacement Cost: The replacement cost of the motor is high, usually ranging from several thousand to tens of thousands of yuan.

6.Other Wearing Parts:

- Bolts, liners, scrapers, etc.: These parts can also wear out or become loose due to long-term use or environmental factors, and need to be inspected and replaced regularly.

The wearing parts of the spiral sand washing machine need to be replaced according to the specific use conditions and frequency.

In order to ensure the efficient operation of the equipment, it is recommended to carry out regular maintenance inspections and replace worn parts in time.

The overall replacement cost may be high, so it is recommended that users choose high-quality original parts when purchasing to extend the service life and reduce the cost of long-term use.