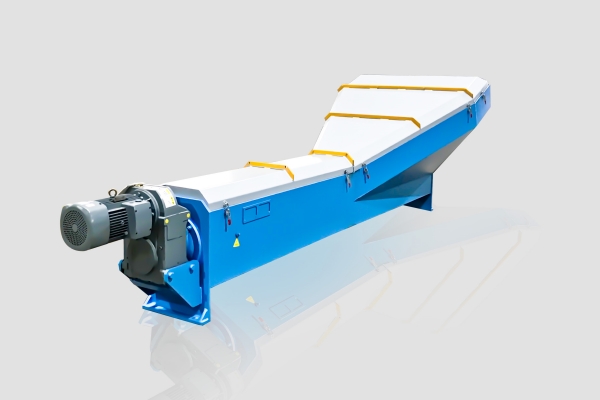

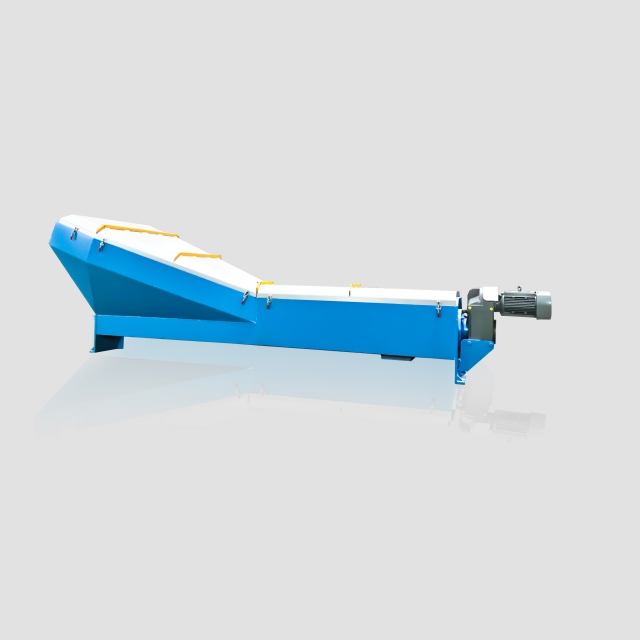

High-capacity Screw Conveyor China Manufacturer & Supplier

RUIJIE is a reliable manufacturer of high-capacity screw conveyors. Designed for heavy-duty use, our conveying machines efficiently handle tough materials and maintain consistent performance in demanding environments. We offer custom solutions tailored to meet the unique needs of each project, making them a trusted choice in mineral, feed, cement plants, Incineration Bottom Ash (IBA) plant,and construction industries.

Features of RUIJIE Screw Conveyor Machine

- The tail axle adopts excavator rollers, which is sturdy and durable, and has good sealing performance.

- The spiral blades are installed with polyurethane rubber sheets in large diameters, which are more wear-resistant, reduce the frequency of replacement of wearing parts, and have a longer service life of the equipment.

- The trough is lined with ultra-high molecular weight polyethylene, which is replaceable, wear-resistant and anti-corrosion, which greatly reduces the wear and corrosion caused by the conveyed materials in the trough and has a long life.

Customized Screw Conveyor Series by RUIJIE

Looking for an efficient and reliable solution for transporting bulk materials? A screw conveyor is designed to move bulk materials using a rotating helical screw, also known as an auger, inside a tube or trough. RUIJIE’s screw conveyor (anger conveyor) is engineered to handle a wide range of materials, offering smooth, continuous flow without disruption. It transports materials at an incline with minimal interruption. Our machines are bulit with durable components. Whether you’re moving powders, granules, or other materials, Our screw conveyors ensure minimal maintenance and long-lasting performance.

Why Choose RUIJIE For Screw Conveyors?

RUIJIE screw conveyors are designed to meet a wide range of material handling needs, offering flexibility and efficiency across various applications. Our team consists of experienced professionals with strong technical backgrounds, ensuring reliable manufacturing processes. We prioritize quality through thorough testing and quality checks at each production stage. With efficient workflows, we are able to offer short delivery times to help keep your projects on schedule. Contact us for a free quote and discover how RUIJIE conveyors can enhance your production efficiency.

What is a Screw Conveyor?

A screw conveyor is a type of mechanical equipment used to move materials from one place to another. It consists of a rotating screw or auger inside a tube or trough. This screw turns and pushes materials along the conveyor. It is commonly used to transport bulk solids, powders, grains, and other similar materials in industries like agriculture, mining, and manufacturing.

Screw conveyors are often preferred for their reliability, efficiency, and versatility. They can handle a wide variety of materials and can be used in both horizontal and inclined settings. The design of a screw conveyor can be customized based on the specific needs of the material being transported.

How Does a Screw Conveyor Work?

A screw conveyor works by using a rotating screw to move materials. The screw is usually powered by a motor, and as it turns, it pushes the material along the conveyor’s length. The shape of the screw allows it to carry materials effectively, even in inclined positions.

Here’s how it works in simple steps:

-

Material Loading: The material is loaded into the conveyor’s trough or tube.

-

Rotation: The screw inside the conveyor turns, driven by a motor or other power source.

-

Material Movement: As the screw rotates, it lifts and pushes the material forward, moving it to the desired location.

-

Discharge: The material exits at the end of the conveyor or at a discharge point.

Screw conveyors are efficient for transporting materials in a continuous, controlled manner. They can be designed for various lengths and angles depending on the application.

What bulk materials can be handled in a Screw Conveyor?

A screw conveyor is designed to transport a wide range of bulk materials across different industries. These include coal, sand, gravel, ores, limestone, gypsum, cement powder, grains, animal feed, ash, and aggregates. Whether in mining, agriculture, cement manufacturing, waste management, or the construction industry, screw conveyors provide an efficient, reliable method for moving these materials.

What are the Advantages of Screw Conveyors?

Screw Conveyors can handle a wide range of materials, from slow-moving semi-solids to free-flowing powders. They are ideal for locations with limited space, as screw conveyors are compact and don’t require a return path like belt or drag conveyors. Our machine are fully enclosed design helps prevent spillage and material contamination during transport.

FAQs

1.After each start, it should be run without load for a certain period of time, and the equipment can be fed only after the normal operation, and the feeding should be kept uniform, and a large number of sudden increases or overload operation should not be allowed.

2.If there are no special circumstances, the load shall not be stopped. Generally, the machine should be stopped after the feeding is stopped, and then when the materials in the standby tank are basically unloaded. If the start occurs after an emergency shutdown for full load transportation, it must be jogged several times or an appropriate amount of material in the casing must be removed.

3.If several conveyor units are combined into an assembly line, the last one should be started first, and then one by one, and the shutdown sequence is reversed. This can also be controlled by electrical interlocks.

1. The Solution to the Insufficient Conveying Capacity

In view of the problem of insufficient conveying capacity of screw conveyor, the following measures can be taken to solve it:

(1) Check whether the position of the feed port is positive, and adjust if it is not regular.

(2) Clean up the blockage at the feed port to ensure smooth feeding.

(3) Check the wear of the spiral blade, and replace it if the wear is serious.

2. The Solution to Excessive Noise

In view of the problem of excessive noise of the screw conveyor, the following measures can be taken to solve it:

(1) Check whether the bearing is damaged, and replace it if it is damaged.

(2) Check whether the position of the feed port is positive, and adjust if it is not regular.

Screw conveyors are essential equipment for moving materials efficiently in various industries. Two popular types of screw conveyors are shafted and shaftless. Each has its unique features, benefits, and uses. Let’s break down the differences so you can choose the right one for your needs.

Screw Conveyor Shafted

A shafted screw conveyor has a central shaft running through the middle of the screw. This shaft supports the rotating screw and helps move materials along the conveyor.

Key Benefits:

-

Durability: The shaft provides additional strength, making shafted screw conveyors more durable for heavy or dense materials.

-

Efficiency: The shaft allows for a more consistent flow of materials, especially in situations with a high material load.

-

Versatility: Shafted conveyors are well-suited for a wide range of industries, from agriculture to manufacturing.

Screw Conveyor Shaftless

Shaftless screw conveyors, as the name suggests, don’t use a central shaft. Instead, the screw is supported by the conveyor casing, allowing for more flexibility and smoother operation.

Key Benefits:

-

Reduced Wear: Without a central shaft, there is less friction, meaning less wear and tear on the system.

-

Maintenance-Free: Shaftless conveyors require less maintenance compared to shafted models, as there are fewer moving parts.

-

Better for Wet or Slippery Materials: Shaftless conveyors excel at handling sticky, wet, or stringy materials like sludge or food waste.

Which One Should You Choose?

-

Go with Shafted if you need to move heavier, more solid materials with a consistent flow.

-

Go with Shaftless if your materials are wet, sticky, or prone to clumping, and you need a system that requires less maintenance.

Ruijie’s screw conveyors are maufactured using high-quality stainless steel for the body, providing excellent durability, corrosion resistance, and easy cleaning. Stainless steel makes these conveyors ideal for handling heavy-duty materials and ensures long-term efficiency.

Additionally, ceramic coatings are applied for enhanced wear resistance. This ceramic layer helps to reduce friction, extend the conveyor’s lifespan, and protect against abrasions and corrosive materials. Our screw conveyors offer a reliable, long-lasting solution for industries requiring efficient and smooth material handling, making them perfect for various industrial applications.