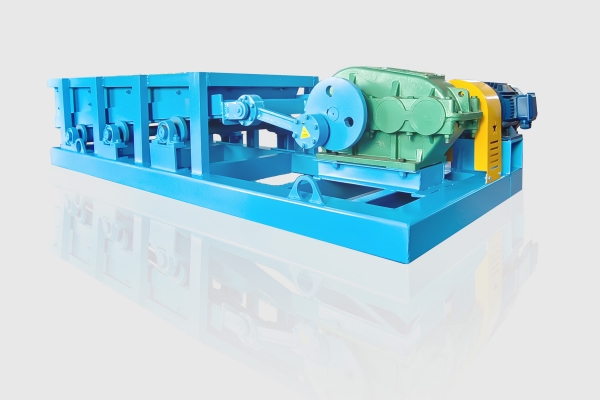

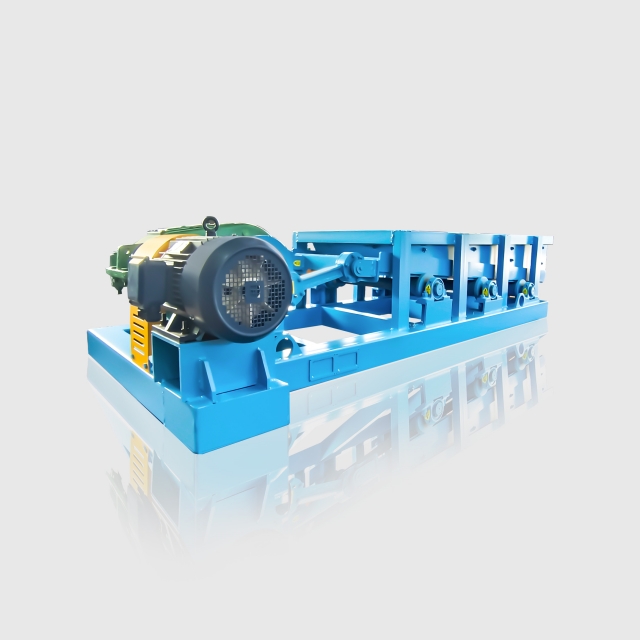

Efficient Automated Reciprocating Plate Feeder-Manufacturer

Reciprocating Plate Feeder is used for feeding coal or other loose granular materials with small abrasiveness and small viscosity.

This machine continuously and uniformly unloads the materials in the storage silo or material pit into the transportation equipment or other screening equipment.

Reciprocating Plate Feeder Features

1. Four sides: wear-resistant Q355B steel plates; double-layer steel bottom plate; replaceable steel lining plate; long lifespan, low maintenance costs.

2. Symmetrical double push rod drive; balanced force distribution, stable transmission, prevents torsion phenomenon.

Why Choose RUIJIE Reciprocating Plate Feeder for conveying all kinds of powder materials?

Our factory specializes in the production of reciprocating feeders, complete models, wear resistance, high quality and low price.

Advantages of Reciprocating Feeder

Compared with vibrating feeder, belt conveyor and screw feeder, reciprocating feeder is more competitive as:

- Higher Impact Resistance

- Better Control for Sticky Materials

- Lower Maintenance for Heavy-Duty Scenarios

- Compact Design for Limited Spaces

- Lower Energy Consumption for Low-Speed Operation

FAQs

1.Operators need to wear safety helmets, suitable work clothes and work shoes to ensure their own safety.

2.Inspect the equipment, including whether all parts of the equipment are in good condition, whether the electrical connections are normal, and whether there are obstacles around the equipment that affect the operation of the equipment.

3.Pay attention to the movement of the feeding trough, and stop the machine for inspection in time if any abnormality is found.

4.While the machine is running, it is not allowed to touch, adjust and force the parts that are running to stop with your hands.

5.Do not jump into the feed chute or into the funnel, and do not face the feeding direction.

6.After the feeder is stopped, the power should be turned off and a safety check should be carried out to ensure that the equipment is safely shut down.

1. Material blocking problem

During the use of the reciprocating feeder, there may be material blockage, resulting in the equipment not working normally. The main reasons are as follows:

1. The Feed is Too Large or Irregular: for different materials, the feed amount of the feeder is different, if the feed amount is too large, it will cause the feeder to be blocked. In addition, if the feed material is irregular, it is also easy to cause clogging.

2. Incomplete Cleaning of the Equipment: The equipment is not cleaned in time during use, resulting in the material remaining in the feeder and forming a blockage.

3. Wear and Tear of Parts: After being used for a long time, the parts inside the equipment may be worn out, resulting in blockage.

Solution: If there is a problem of blockage, you can stop the machine for inspection first to find the blockage location. Then, depending on the situation, different solutions can be chosen, such as cleaning the equipment, reducing the amount of feed, replacing worn parts, and so on.