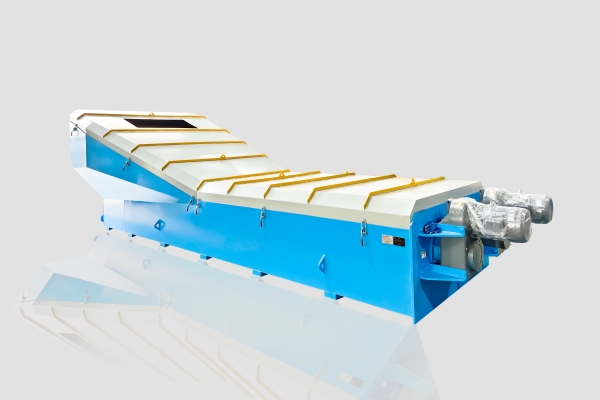

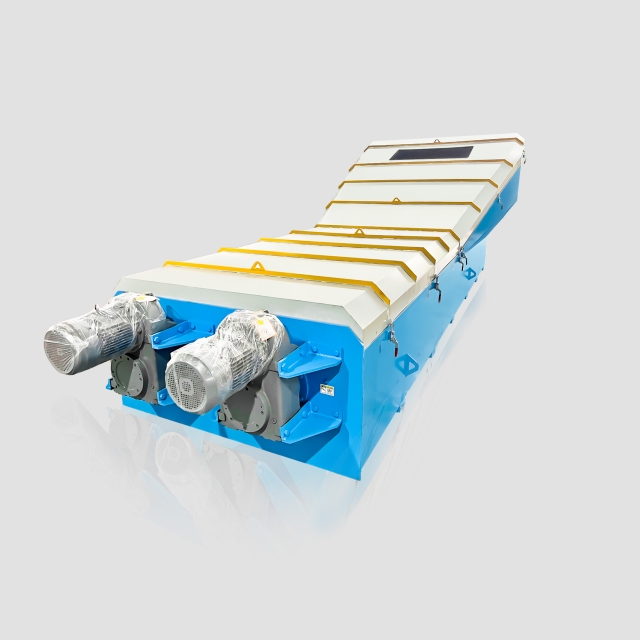

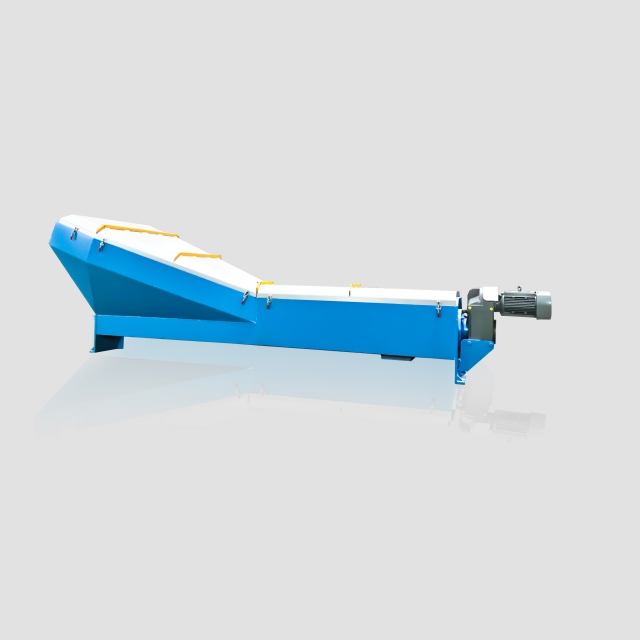

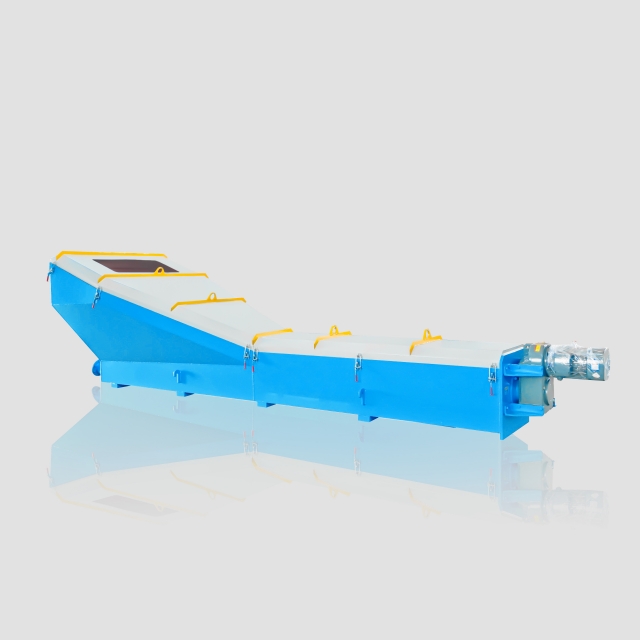

High-efficiency Industrial Conveying Machine From China Manufacturer

RUIJIE’s industrial conveying machine can improve your material handling capacity. Our machines are built for rugged, non-stop operation. High load-bearing capacity and optimized structure ensure smooth and reliable transport of heavy or abrasive materials. Whether you’re dealing with ore, crushed rock, metal waste, or recyclable components, RUIJIE’s machines help maintain production efficiency, reduce manual labor, and minimize downtime.

Features of Conveying Machines

- Low power consumption and high cleanliness. Small cross-sectional area, good sealing,

- The loss of washed materials is small, the selection and washing efficiency is high, and it can fully meet the requirements of high-grade materials.

- It has the advantages of simple structure, convenient operation, easy maintenance, and convenient closed transportation.

RUIJIE Conveyor Machine Seires

RUIJIE is a trusted manufacturer and supplier of industrial conveying machines designed for high-efficiency material handling in mining, recycling, metallurgy, and heavy manufacturing. Our conveyors are engineered for demanding environments, offering continuous, stable transport of scrap components throughout your recycling line.

We offer wide range of conveying systems, including screw conveyors, screw conveyor with washing function, and reciprocating conveyor, each available in standard and custom configurations to match your plant layout, material flow, and handling requirements.

Why Choose RUIJIE For Industrial Conveying Machines?

With its excellent performance and durability, RUIJIE industrial conveyors reduce equipment downtime and ensure the smooth operation of the production line.

With a strong track record in China and across global markets. At RUIJIE, we oversee every part of the production process, ensuring consistent quality and fast lead times. This control allows us to maintain the integrity of each unit and deliver on schedule.

Whether you need a single unit or a wholesale supply, RUIJIE is your trusted partner for high-quality, efficient conveying solutions.

Benefits of Conveying Machine

- Durable Structure: Manufactured with high-strength steel and wear-resistant components to handle tough industrial conditions.

- Stable Performance: Consistent conveying speed and torque for uninterrupted material flow.

- Customizable Design: Length, width, speed, and material configuration tailored to your operational needs.

- Easy Integration: Compatible with existing equipment and factory layouts.

- Low Maintenance: Simplified mechanical structure with minimal moving parts for reduced service time.

Application of Industrial Conveyors

RUIJIE conveying machines are widely used across construction, mining, and recycling industries for efficient and reliable material handling.

- In construction projects, they streamline the transfer of sand, gravel, and cement, ensuring steady supply to batching plants and reducing manual labor on-site.

- In mining operations, RUIJIE conveyors are built to handle heavy loads of ores, crushed rock, and tailings under harsh conditions, improving transport efficiency and operational safety.

- For recycling facilities, our systems support the movement of scrap metals, plastics, and industrial waste across sorting and separation lines, enabling continuous processing and better material flow.

With durable construction and customizable configurations, RUIJIE conveyor machines adapt easily to the demands of each application scenario.

FAQs

The daily maintenance and maintenance of the conveying equipment is the key to ensure the efficient operation of the equipment for a long time and prolong the service life. Here are some common routine maintenance and upkeep measures:

1.Clean The Equipment:

- Regular Cleaning: After each use, the inside and outside of the equipment should be cleaned, especially to remove sand residue from the spiral blades and washing tanks to prevent clogging and wear and tear of the equipment.

- Prevent Rust: Avoid long-term water accumulation during the cleaning process, especially in a humid environment, and regularly check and clean water stains on the surface of the equipment to prevent rust.

2.Inspect The Wearing Parts:

- Helical Blade: Regularly check the wear of spiral blades, and replace them in time when the wear is serious, so as to ensure the sand washing effect and equipment efficiency.

- Bearing: Check the lubrication of the bearing to ensure that the bearing runs smoothly. Add lubricating oil if necessary to avoid bearing wear or overheating due to insufficient lubrication.

- Motors andTtransmission Parts: Regularly inspect motors, belts, gears and other transmission components to ensure that they are operating properly and that the fasteners are not loose.

3.Check The Running Status Of The Device:

- Electrical System: Check the electrical wiring and control panel to ensure that all connections are tight and the control system is working properly. If an abnormal situation is found, it should be repaired in time.

- Noise And Vibration: Pay attention to observe whether there is abnormal noise or excessive vibration when the equipment is running, which may be a sign of internal failure or loosening of the equipment, which needs to be checked and repaired in time.

4.Lubrication Maintenance:

- Lubrication: Regularly check the quantity and quality of lubricating oil, replenish and replace lubricating oil in time, keep the equipment running smoothly, and reduce friction and wear.

5.Regular Maintenance And Record:

- Periodic Maintenance: It is recommended to carry out a comprehensive maintenance at regular intervals (e.g., monthly or quarterly) to check the tightening of bolts, the wear and tear of various components of the equipment, and the safety of the electrical system.

- Maintenance Records: Establish equipment maintenance records, record the time, content, problems and treatment measures of each inspection and maintenance in detail, so as to facilitate future reference and tracking of equipment status.

Through the above daily maintenance and maintenance measures, the service life of the spiral sand washing machine can be effectively extended and the long-term stable operation of the equipment can be ensured

The power consumption of the conveyor mainly depends on the model, power and usage conditions of the equipment. Here are some common scenarios about how your device consumes power:

1.Power Consumption Of The Device:

- Power Range: The motor power of the spiral sand washer is usually between 5.5 kW and 30 kW, depending on the model and processing capacity of the equipment.

- Power Consumption Calculation: Assuming that the motor power of the equipment is 15 kilowatts, the power consumption for 1 hour of continuous operation is about 15 kilowatt-hours (kWh). If the device has less power or has a shorter period of use, the power consumption will also be reduced accordingly.

For Example:

The power consumption of a small device (5.5 kW) is approximately 5.5 KWH/h.

The power consumption of a medium-sized device (15 kW) is about 15 KWH/h.

The power consumption of large equipment (30 kW) is about 30 KWH/h.

The power consumption of the spiral sand washer depends largely on the specific model and working conditions of the equipment.

In order to reduce energy consumption and operating costs, it is recommended to choose equipment with frequency conversion control or automatic shutdown function, or appropriately adjust the operating status of the equipment according to the load situation in actual operation to achieve energy saving effect

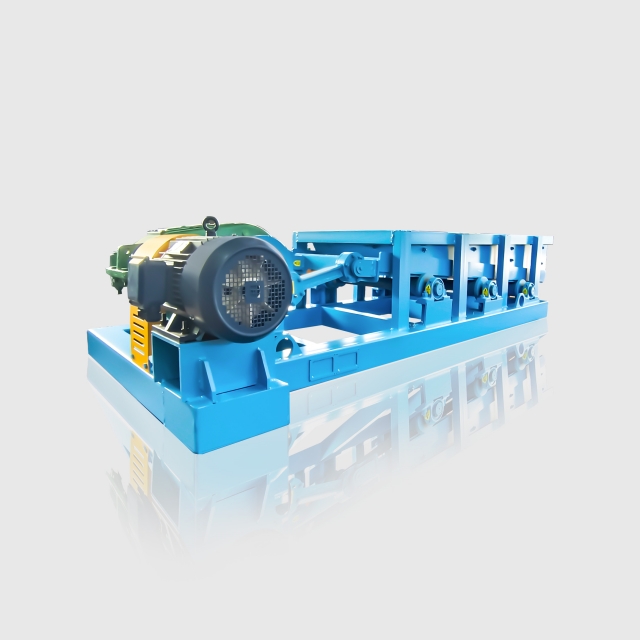

RUIJIE’s screw conveyors use a rotating shaft with helical blades to push material forward. In reciprocating conveyors, materials are moved by a tray that slides back and forth. Each design is suited to different types of materials and processing needs. The goal is always the same: stable, automated movement of materials to reduce labor, improve safety, and keep production lines running smoothly.

At RUIJIE, we providet wo main types of conveying equipment: screw conveyors and reciprocating feeders.

The screw conveyor is ideal for transporting bulk materials such as sand, cement, or powder. It use a rotating screw to push materials. RUIJIE‘s screw conveyor can be equipped with a sand washing system, turning it into a machine that not only conveys but also cleans materials in one process.

The reciprocating feeder moves materials using a back-and-forth motion. It’s well-suited for heavy-duty applications that require controlled feeding or batch discharge. This design helps maintain consistent material flow