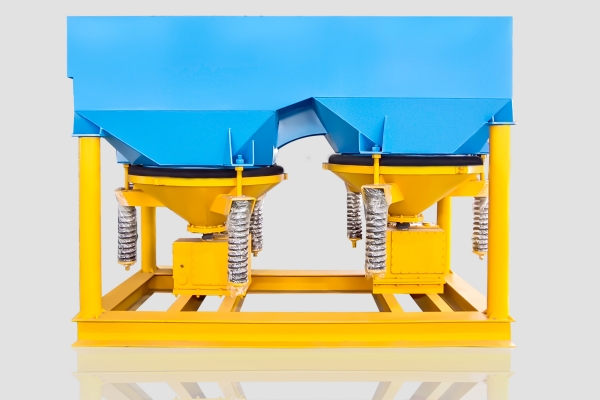

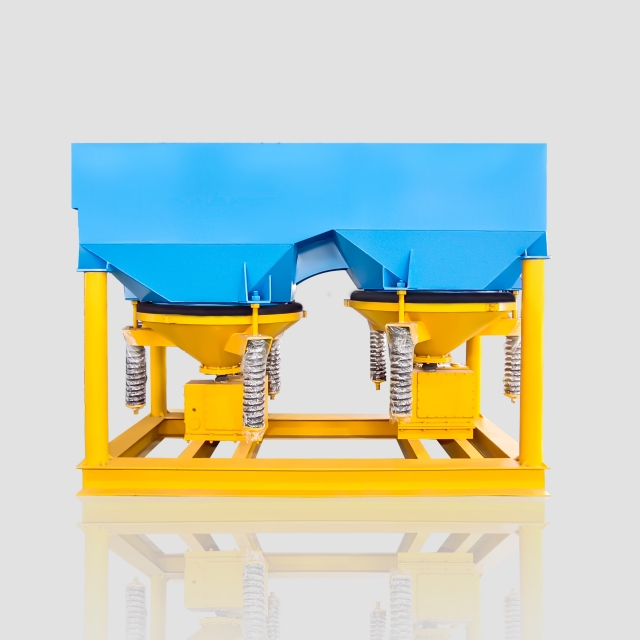

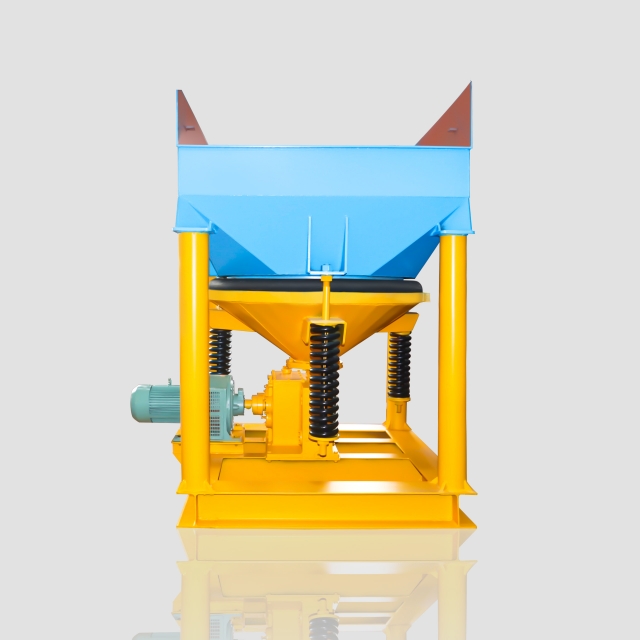

Reliable & High Quliaty Jig Concentrators From China Manufacturer

RUIJIE is your trusted manufacturer, providing high-performance jig concentrators for coarse-grain ore separation. Designed for efficient recovery of copper, silver, coltan, tin, tungsten, diamond, barite, iron, manganese, fluorite, and garnet, our machines ensure precise stratification using gravity-based technology. Built for durability and energy efficiency, RUIJIE’s solutions enhance mineral recovery without chemicals, making them ideal for mining and recycling industries.

Features of Jig Concentrators

- Jig machines are made of Q335B steel and has Wear resistance, corrosion resistance, long service life.

- The core part of the machine has good sealing, dustproof and waterproof, good reliability and long service life.

- The cam mechanism is used to drive, and the zigzag waveform ripple curve generated makes the jigging rising water flow uniform and the descending water flow is rapid, which effectively improves the recovery rate of fine-grained useful minerals.

RUIJIE Mineral Jig Separator Series

Jigging is a widely used mineral processing technique that separates materials based on density differences. It is a gravity-based method where water pulsation helps stratify particles, allowing denser materials to sink while lighter ones rise. This process is essential in mining and recycling industries, offering an efficient and cost-effective solution for ore beneficiation.

How Jigging Separation Works

Jig concentrators use a pulsating water flow to create alternating high and low-pressure zones. As the material moves through the jig bed, heavy minerals like copper, silver, coltan, tin, tungsten, and iron settle at the bottom, while lighter waste particles are washed away. This method enhances ore recovery and purity without requiring chemicals, making it an eco-friendly solution for mineral processing.

Why Choose RUIJIE Jig Concentrators For mineral industry?

Looking for a cost-effective and efficient mineral separation solution? RUIJIE’s advanced jig concentrators deliver high performance and long-term reliability.

Our expertise in gravity separation of coarse-grained ore types and our commitment to precision engineering ensure that the products we deliver meet the most stringent specifications.

We provide competitive prices, complete sets of jig machinery and process flow, free beneficiation experiments and equipment installation and commissioning throughout the project.

Applications of Jigging in Mineral Processing

Jigging separation is highly effective for coarse-grain ores, including:

- Precious and base metals – Copper, silver, and tungsten

- Rare and industrial minerals – Coltan, fluorite, and garnet

- Heavy minerals and gemstones – Diamond and barite

- Iron and manganese ore – Enhancing grade and recovery

Advantages of Mineral Jig Concentrators

- High recovery rates – Effectively concentrates valuable minerals

- Eco-friendly – No chemicals required, reducing environmental impact

- Energy-efficient – Low operational costs compared to other separation methods

- Versatile – Works on various ore types and particle sizes

FAQs

1.Tighten the knob of the electromagnetic speed control motor control device to the minimum;

2.Open the water filling valve under the sieve, and turn on the motor after the jig chamber is filled with water

3.After the motor speed is stable, slowly rotate the knob of the electromagnetic speed regulating motor control device to adjust the stroke of the jig;

4.After confirming that the equipment is running normally, the ore will be evenly fed. Adjust the stroke of the equipment appropriately to achieve the ideal beneficiation effect.

5.Before the shutdown, the ore feeding must be stopped, and after the mineral separation in the jigging room is completed, the knob of the speed control device is turned to the zero position, the power supply of the speed control device must be turned off, and the power supply of the motor must be turned off.

Jig machine beneficiation has the advantages of good separation effect, large processing capacity, wide range of sorting particle size, low investment, low production cost and simple process system, so it is widely used in the gravitational separation and beneficiation process.

Jig machine as an important equipment in the process of gravity separation, its operation is directly related to the quality of the product and the economic benefits of the concentrator, when the jig has abnormal problems may affect the normal operation of the process after that, to deal with it in time. Therefore, it is important to understand the common problems of jig machine and how to deal with them.The following is an introduction to the causes and solutions of several common problems of jig machine.

1.The Sieve Plate Of The Jig Machineis Loose or Cracked

During operation, if you find that the sieve plate beats with the pulsating water flow, it means that the screws of the sieve plate are loose or have fallen. If a certain part of the bed is found to be in a certain part of the bed during the rising period of water flow, the liquid level gushes out like a spring; During the period of water decline, the water flow falls very quickly, and at the same time, the material in the hoist body increases significantly, indicating that the sieve plate has cracked into a hole.

Solution: If the screws of the sieve plate are loose or falling, stop the machine immediately to clean the bed and tighten the screws; If the sieve plate is broken, it is necessary to stop the machine to drain the water, clean the bed, and repair the leakage of the sieve plate.

2.The Bed Of The jig machine is Emptied

The thickness of the bed is related to the properties of the material being processed (density and particle size), and in normal production, the bed must maintain a certain thickness and make it stable. However, sometimes due to the large opening of the gate or the improper adjustment of the automatic discharge device such as the electrode of the pressure test, the discharge is too much, resulting in the phenomenon of bed emptying.

Solution: When the bed emptying phenomenon occurs, it should be dealt with in time. Adjust the gate opening and electrodes to the appropriate position, and readjust the bed layer to make the bed thickness appropriate.

3.There Is A Problem With The Jig Machine Discharge System

In the discharging process, the supporting bending plate of the discharging system of the jigging machine is dislocated, so that the gap between the supporting bending plate and the lifting wheel is uneven, and the narrow part is rubbed, and the material overflows in the part with a large gap, so that the unsorted material enters the product. This is caused by the displacement of the lift wheel in the lift lane or the deformation or loosening of the support plate.

Solution: Adjust the lifting wheel support device and the guide wheel position in time during daily maintenance, and maintain the normal working position of the lifting wheel in the wheel path; Tighten the connecting bolts of the support bending plate in time and correct the deformed support bending plate.

4.Jig Machine Solenoid Valve Failure

When the solenoid valve of the jig is blocked, the sealing ring is leaking, etc., it is mostly caused by the failure of the air filter, the high-pressure air with water or impurities, and the failure to clean the solenoid valve during inspection. When the coil is broken or the wiring contact is poor, it will also cause the solenoid valve to be energized without a suctioning sound.

Solution: Clean the solenoid valve regularly, replace the sealing ring and coil, and replace the air filter.

The above is the common problems and solutions in the work process of the jig machine, special attention should be paid to the fact that there are many reasons for the failure, when the jig machine has a problem, the operator should analyze the specific problem. At the same time, it is recommended that all mine owners find equipment manufacturers with the overall qualification of the concentrator to purchase and maintain jigs to avoid the impact on the overall operation of the concentrator due to mechanical failure.

A jig machine is a device used in the jigging process to separate particles based on their density. It works by creating a pulsating motion, typically through water or air, which causes the material to stratify. In the jig machine, denser materials move downward, while lighter materials rise to the top. This makes it easier to collect and separate different types of materials. Jig machines come in different sizes and designs depending on the application, and they are widely used in industries such as mining and recycling. They provide an efficient, cost-effective way to sort materials.

The jigging process is a type of gravity separation used to separate materials based on differences in their density. The process involves a pulsating movement, usually in the form of water, which creates a vertical flow. Heavier particles sink to the bottom, while lighter particles are carried upward by the flow. This method is highly effective in sorting materials like minerals or metals, as it helps separate valuable minerals from waste materials. The jigging process is often used in industries like mining, where efficient and cost-effective separation of different materials is crucial.