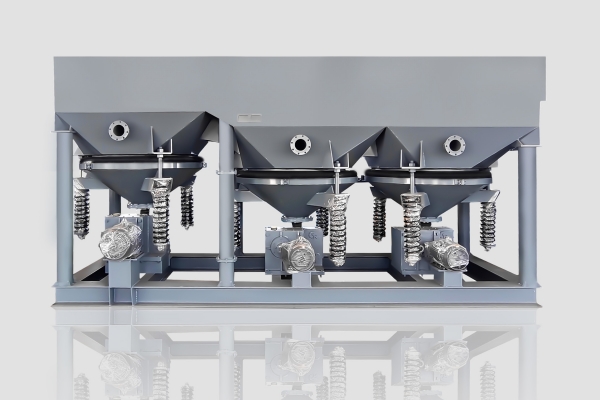

High Performance Gravity Sorting Machine From China Manufacturer

RUJIE’s Gravity Sorting Machine is a top-tier solution for various industries, including copper, silver, tungsten, incineration bottom ash (IBA), titanium, raw ore, and chrome sand separation. As a direct manufacturer, we offer customized gravity sorting machines designed for high-performance and efficiency, meeting the needs of both small-scale and large-scale operations.

Features of Our Gravity Sorter

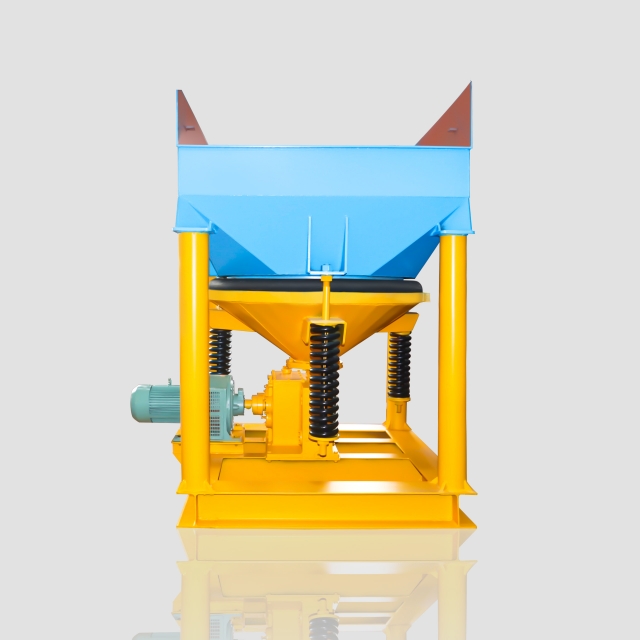

- Our jig machines are equipped with pulsating water flow, which improves separation accuracy in a variety of applications.

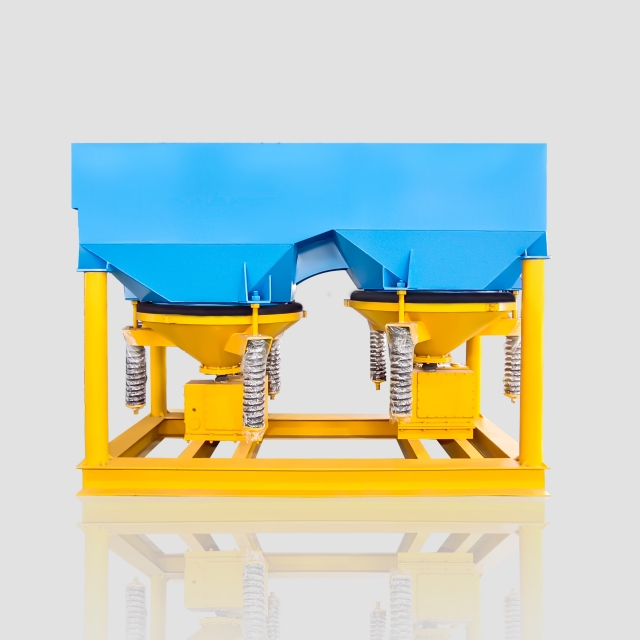

- Compact structure, small footprint and relatively stable performance, and is one of the ideal equipment for small-scale gravity beneficiation.

- Under the same conditions, it has the advantage of more water saving than other types of jig machine, and can also be used in remote water shortage areas.

- The whole machine is made of high-quality Q355B steel, which is more wear-resistant, corrosion-resistant, and has a longer service life.

RUIJIE Gravity Separation Series

RUJIE is committed to providing high-quality equipment for various industries. Our gravity sorting machines are engineered for high performance, helping you achieve effective separation while optimizing resources. Whether you are processing copper, silver, or other materials, our machines are built to deliver results.

- Customizable: Tailored solutions to meet the specific needs of your separation process.

- High Efficiency: Advanced features for better performance and resource optimization.

- Durable and Reliable: Long-lasting materials and stable design for minimal downtime.

- Cost-Effective: Reduced water consumption and low maintenance costs.

Why Choose RUIJIE For Custom Gravity Sorting Machines?

Need a reliable, high-performance gravity sorting machine? RUIJIE specialize in offering direct manufacturing and tailored solutions for your business needs. We peovide custom jigging chambers in square numbers and quantities, colors, and more to meet your specific material gravity sorting efficiency and hourly throughput requirements. RUIJIE offers jig concentrators with superior durability and the ability to resist extreme temperatures and harsh environments. Get in touch with us now for more information and a free consultation!

Benefits of Using Gravity Sorting Machines

-

Pulsating Water Flow for Enhanced Separation

Our jig machines are equipped with a pulsating water flow system that significantly improves separation accuracy. This feature ensures optimal performance across a wide range of materials, including heavy metals and ores. -

Compact and Stable Design

With a compact structure and small footprint, the RUJIE Gravity Sorting Machine is ideal for environments where space is limited. Despite its small size, it delivers stable and reliable performance, making it an excellent choice for small-scale gravity beneficiation operations. -

Water Efficiency

Our machine excels in water efficiency, consuming less water compared to other jig machines under the same conditions. This makes it an excellent choice for areas with limited access to water, reducing operational costs and environmental impact. -

Durable Construction for Long-Lasting Use

Constructed with high-quality Q355B steel, our Gravity Sorting Machine is built to withstand wear and corrosion. This ensures a longer service life, even under demanding operating conditions, providing customers with reliable, long-term performance.

FAQs

1.Check whether the size gear is displaced, and fix it after adjustment.

2.Check the grease in the bearing to ensure that the equipment can run smoothly.

3.Check whether the installation of parts is stable and whether the jigging function is normal.

4.After the adjustment is secure, the jig can be tested for two hours to check whether all parts are loose and worn.

5.The motor of the equipment uses 380V three-phase AC power supply, and the electromagnetic speed control device uses 220V AC power supply (the line connection between the control device and the motor refers to the instructions for the use of the speed control device).

6.Before starting the equipment, check whether the steering of the motor is correct, whether the fasteners are loose, whether the lubricating oil filling meets the requirements, and whether the water and pressure under the sieve meet the requirements.

The quality of Gravity Sorting Machine maintenance not only affects the life of the equipment, but also has a great impact on the selection effect. Due to the different types of jig machines, it also has a different maintenance focus. Only the maintenance of diaphragm jig is introduced here, and its key maintenance items are as follows:

1. Strengthen The Maintenance of The Screen

The quality of the screen directly affects the sorting effect of the jig concentrator. The installation of the screen should be smooth and tight. The screen should be cleaned frequently to prevent clogging. When the screen is worn, it should be repaired or replaced in time.

2. Strengthen the Maintenance of The Diaphragm

The diaphragm of the jig Concentrator is a rubber product, which should be flat and tight when installed, and should not leak when agitated, and protect the diaphragm from damage. If the diaphragm is found to be damaged, it should be repaired or replaced in time.

Gravity separation is a method used in mineral processing to separate valuable minerals from waste material using the force of gravity. The process relies on differences in the density of minerals. When a mixture of minerals is placed in water or a fluid, the heavier particles tend to sink, while the lighter ones float. This simple yet effective technique is often used for materials like gold, tin, and coal. Gravity separation doesn’t require chemicals or high-tech equipment, making it an environmentally friendly and cost-effective choice for mining operations.

Gravity separation works best with materials that have a significant difference in their density. It is commonly used for separating ores like gold, copper, iron, and coal. Heavy minerals, like gold, tend to separate easily from lighter materials such as sand or clay. Other materials that can be separated using gravity include minerals like tin, wolframite, and some gemstones. The key to successful gravity separation is choosing materials where the difference in density is large enough to make them easy to sort by gravity.