Among all sustainability approaches, scrap metal recycling leads as an environmentally friendly practice that preserves energy resources while preventing damage to mining operations. The process of identifying which materials to recycle correctly starts with knowing how to detect different types of scrap metal. This article presents major techniques to identify scrap metal that enables better recycling practices.

What Is Scrap Metal?

Scrap metal represents all metal materials that humans discard from use for new purposes. Scrap metal originates from old appliances together with cars and construction materials, and industrial waste items. The main reason to recycle scrap metal involves recovering useful substances from the discarded material to eliminate further dependence on mining fresh metal.

Ferrous metals constitute one category while non-ferrous metals form the other category within the scrap metal classification system. Any metallic substance that includes iron makes up ferrous metals, but non-ferrous metals lack iron completely. Checking the specific metal category remains essential before starting sorting or recycling processes.

How Can You Identify Scrap Metals?

New practitioners might face difficulties when sorting out scrap metal, yet various identification techniques will assist in separating different metal types. You should search for these primary indicators when distinguishing different types.

Identify Metal by Color

Metal identification often begins with examining its color, for which metals have distinctively different tones. You can distinguish various metals because they exhibit different color tones. For example:

- Copper shows itself as reddish-brown while its oxidized form produces a greenish patina.

- Aluminum shows itself in silver-gray hues and appears dull with a matte finish.

- Brass exhibits a yellowish gold color that shines brightly.

- The usual gray or silver appearance of steel may develop a reddish-brown rust after encountering moisture exposure.

- Lead material displays a softly gripping gray color.

Color examination of the metal reveals the likely type, although it requires additional testing for precise identification.

Identify Metal by Hardness

Metal identification can also be achieved by testing how hard the material is. The level of tenderness of a metal material determines its resistance to deformation and scratching. The hardness of metals such as iron and steel exceeds the level of metals such as aluminum, which demonstrates lower hardness. A scratch test lets you determine stiffness through attempts to hurt the metal with a pointed instrument.

- Visibly detectable scratches emerge on aluminum and lead because these metals are soft.

- When exposed to scratches, stainless steel, together with iron will show either low scratch visibility or completely resist scratching.

Hardness can also give clues about the alloy composition, which is especially useful for metals used in industrial applications.

Identify Metal by Luster

Metallic sheen provides valuable information to identify the substance. The reflective and shiny attributes distinguish stainless steel and aluminum from brass, which demonstrates a gold-like appearance. Metals that include iron display a smooth matte effect, which transforms into a reddish reflective appearance during cleaning.

Identify Metal by Oxidation

The combination of metal with oxygen through oxidation leads it to degenerate gradual. Visible marks resulting from oxidation enable us to identify different metals. For example:

- When copper oxidizes, it develops a green appearance, which can be observed on both old coins and roofs.

- Fresh exposure to water causes iron and steel to rust into a reddish-brown appearance.

- Aluminum stays non-rusted yet produces whitened, crusty oxides during air exposure.

Oxidation analysis provides an efficient approach to determine metal types, particularly in old and weathered objects.

Identify Metal by Weight

Upon touch metal weight provides an indicator for metal identification purposes. A weight comparison shows that different metals have various densities. For example:

- Lead exists as a very heavy component among other metals because of its extremely dense texture.

- Metallic aluminum maintains sturdy properties, although it remains extremely light in weight.

- Metal weight varies widely because different steel alloys possess different densities, from light to heavy.

- Copper has a greater density than aluminum, together with substantial weight relative to other kinds.

By holding the metal in your hands, you will gain some insight into its weight characteristics, yet you should do extra assessments to verify its actual nature.

Identify Metal by Original Usage

The source of metals together with their original functions assists in their identification. For example:

- Copper serves multiple functions as an electrical wiring material, and plumbing pipe material and a roof-related material.

- You can usually find aluminum in wind frame assemblies and beverage containers, and aircraft fuselages.

- Heavy equipment, appliances, and automobiles alongside bridges contain steel as their main material component.

- Items under the categories of decorative objects and locks, as well as musical instruments, frequently contain brass.

Your understanding of what purpose or typical application specific metals serve will enhance their identification. Identifying the original use of an old appliance component enables you to find the material through functional assessment.

Why Manual Identification Isn’t Enough

While traditional identification methods—like checking color, weight, or hardness—can work in small-scale settings, they are inefficient and unreliable for industrial operations. Manual sorting becomes slow, inconsistent, and prone to misclassification when faced with high volumes of mixed or contaminated scrap. Human error can lead to lower recovery rates and increased contamination between metal types, directly affecting the quality and resale value of recycled materials.

Industrial recycling demands speed and precision. This is where specialized sorting equipment becomes essential. By automating the separation of ferrous and non-ferrous metals, these machines reduce dependency on manual labor and improve overall processing accuracy. They also help facilities comply with safety and environmental standards by minimizing incorrect disposal of hazardous metals such as lead or mercury-bearing components.

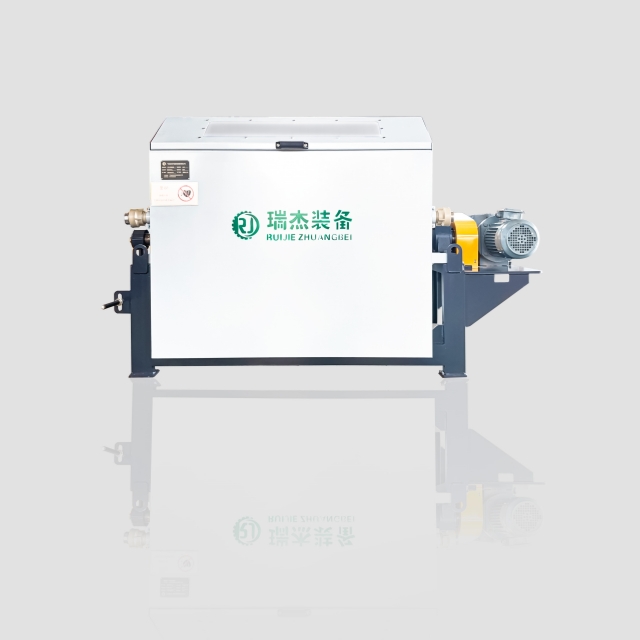

RUIJIE’s Magnetic and Eddy Current Separators

For industries involved in large-scale metal recycling, RUIJIE offers cutting-edge magnetic separators and eddy current separators that provide efficient solutions for recovering valuable metals from complex waste streams. These high-performance systems are specifically designed to handle materials that are challenging to sort manually, such as:

-

Auto shredder residue: Waste from dismantled vehicles, including mixed metals and plastic that require precise separation.

-

Incinerator bottom ash: Ash from waste incineration processes that often contain valuable metals mixed with other non-metallic materials.

-

Mineral slags: Byproducts from metal refining that may still contain recoverable metallic elements.

-

Electronic and household appliance waste: Discarded electronics and appliances that contain a wide range of ferrous and non-ferrous metals.

Magnetic separators efficiently remove ferrous metals from waste streams, ensuring that iron and steel are extracted for further processing. Eddy current separators, on the other hand, are specifically designed for high-speed sorting of non-ferrous metals such as aluminum, copper, and zinc, ensuring that even small particles of these valuable metals are recovered.

By integrating these advanced systems into your recycling process, industries can dramatically improve sorting precision, increase the recovery rate of high-value metals, and reduce labor costs. Additionally, these systems help protect downstream processing equipment from contamination, ensuring smoother and more cost-effective operations.

Conclusion

Accurate identification of metal to be recycled plays a vital role in maximizing recycling efficiency. While basic methods like color, hardness, and oxidation offer a starting point, industrial settings benefit most from automated systems.

RUIJIE’s equipment supports efficient recovery of both ferrous and non-ferrous metals, promoting sustainable operations. Whether you’re processing construction scrap, incinerator residue, or shredded car parts, using the right separation equipment is essential to unlock full value from your metal waste.