How Does A Wet Magnetic Separator Work?

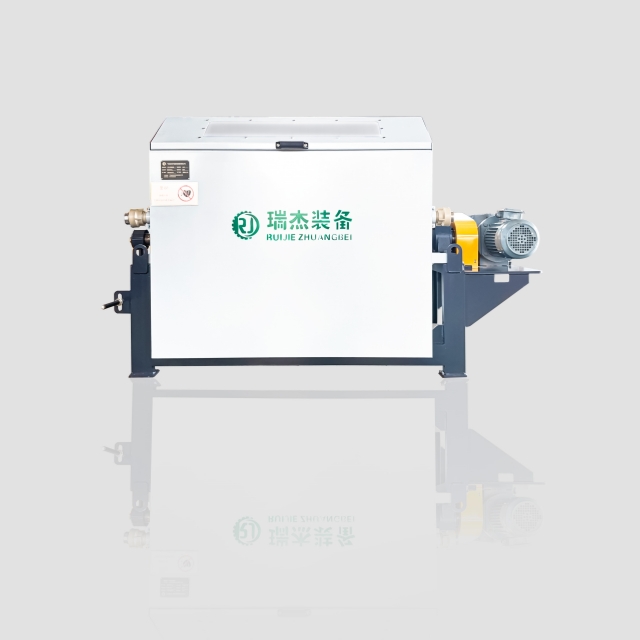

How Does A Wet Magnetic Separator Work?The working principle of the Wet Magnetic Separator is that when the slurry or incineration bottom ash (IBA) enters the magnetic field area, the strong magnetic minerals are adsorbed on the surface of the cylinder.

The weak magnetic and non-magnetic minerals are thrown off and discharged, and the strong magnetic minerals adsorbed on the surface of the cylinder rotate with the cylinder, are taken out of the magnetic field area, and are washed into the concentrate tank with flushing water to complete the separation of magnetic particles.

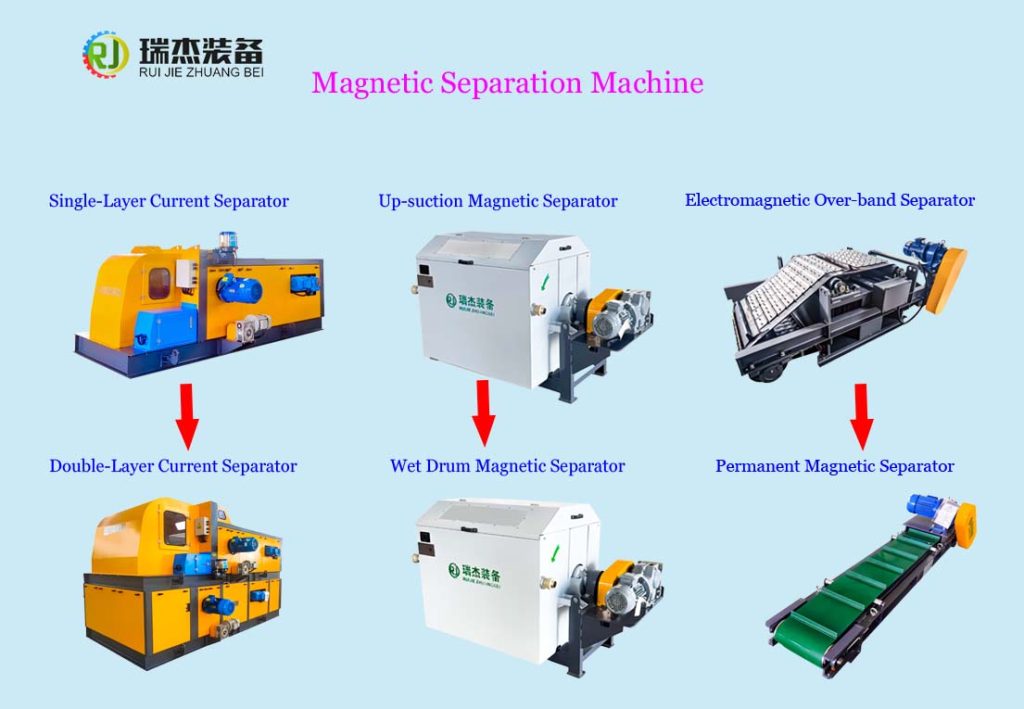

Dry Magnetic Separator and Wet Drum Magnetic Separator

The magnetic separator is specially developed for the separation of magnetic minerals, and we generally think of iron ore.

There are many types of magnetic separator, mainly divided into Dry Drum Magnetic Separator and Wet Drum Magnetic Separator. In the process of iron ore magnetic separation, the dry magnetic separator is mainly used for the process of pre-casting, while the wet magnetic separator equipment is mainly used for the magnetic separation process after grinding and other processing processes.

Magnetic Drum Separators with Different Rotation Directions

Guangxi Ruijie Slag Equipment Manufacturing Co., Ltd. produces wet magnetic separators that are commonly used to screen magnetic metals in magnetite, orpimentite, ilmenite, and incineration ash (IBA) below 3mm.

According to the flow direction of the slurry and incineration bottom ash (IBA), it is divided into downstream wet magnetic separator, countercurrent wet magnetic separator and semi-countercurrent wet magnetic separator, and no matter which type of wet magnetic separator can improve the recovery rate of concentrate powder and magnetic metal particles.

Conclusion

The company provides experimental prototypes of various magnetic minerals, which can make iron separation processes according to customers’ different ore samples, materials, mineral processing requirements, mineral tastes, and different ore processes, as well as provide experimental results and data, recommend suitable iron removal equipment for customers according to on-site tests.

We can meet the ideal requirements, and debug equipment for customers on site, and professionally train operation and maintenance personnel for users to ensure the normal operation of the production line.

Welcome new and old customers to bring ore samples or materials to our company for experiments!