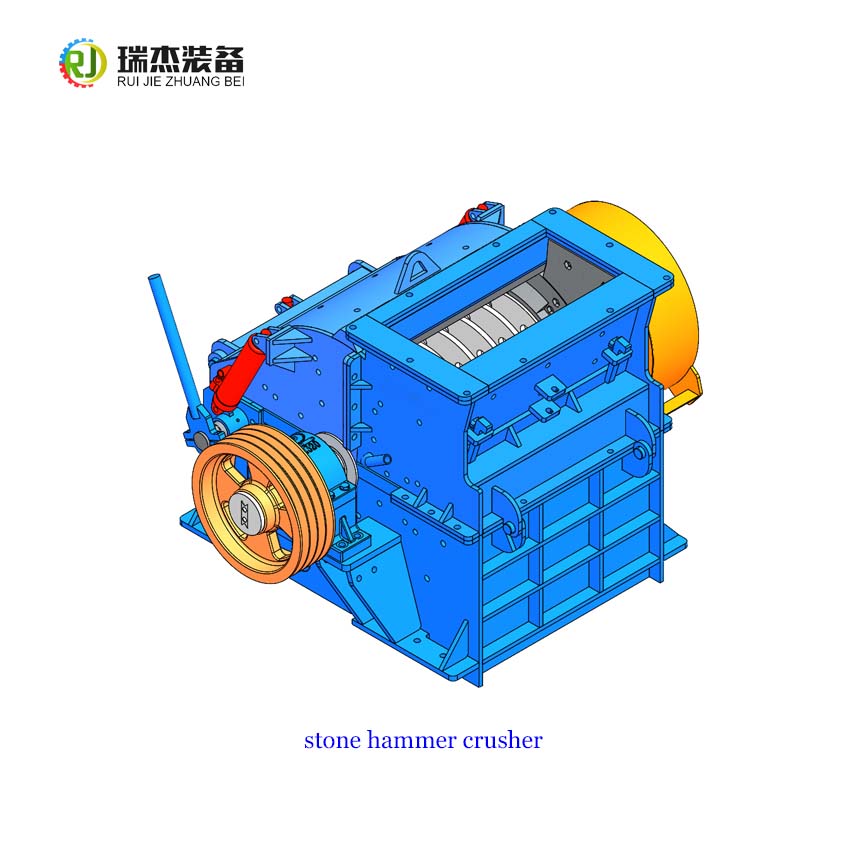

A hammer crusher uses high-speed hammers to crush materials through impact. This machine processes brittle materials like limestone, coal, and gypsum. Industries such as mining and recycling rely on it for efficient material reduction. The crusher’s design ensures consistent performance, making it a vital tool for breaking down hard substances into smaller, manageable sizes.

The Working Principle of a Hammer Crusher

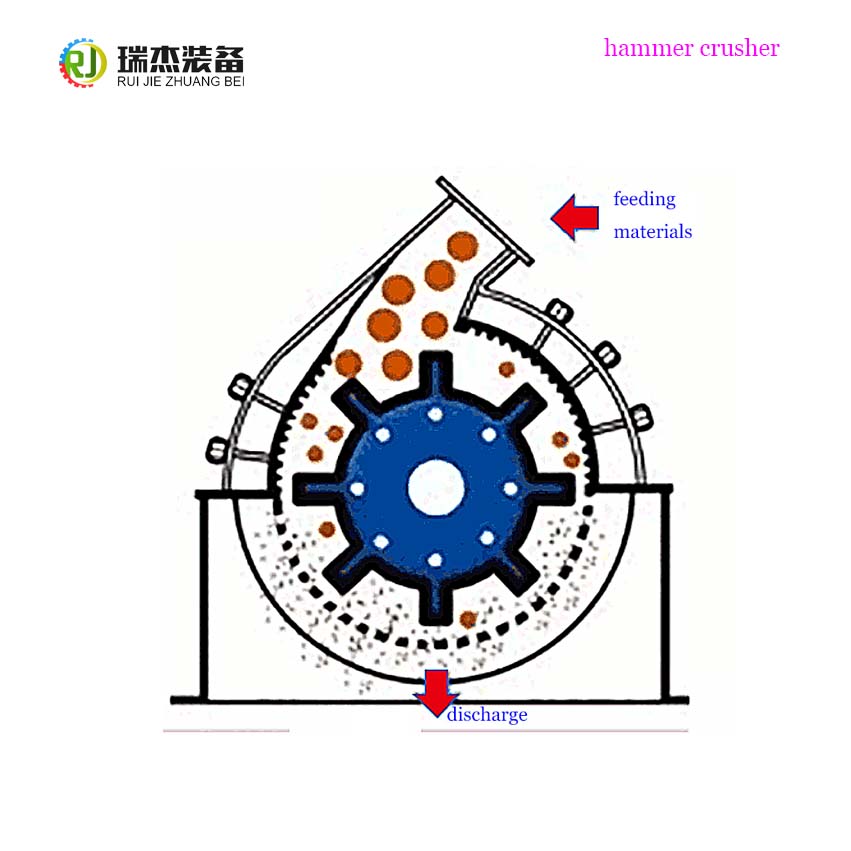

How materials are fed into the machine

The hammer crusher begins its operation by receiving materials through a designated feeding system. This system ensures a steady flow of materials into the machine. A hopper or chute typically guides the materials into the crushing chamber. The design of the feeding mechanism prevents blockages and ensures uniform distribution. Proper feeding is crucial for maintaining the crusher’s efficiency and avoiding unnecessary wear on its components.

The role of high-speed rotating hammers

Inside the crushing chamber, high-speed rotating hammers play a central role in the working principle of the hammer crusher. These hammers, attached to a rotor, spin at high velocities. As the rotor rotates, the hammers strike the materials with immense force. This impact shatters the materials into smaller fragments. The speed and arrangement of the hammers determine the crushing efficiency and the size of the output material.

The impact and discharge process

After the initial impact, the broken materials collide with the walls of the crushing chamber and other fragments. This secondary impact further reduces their size. Grate bars located at the bottom of the chamber control the final size of the discharged material. Only particles small enough to pass through the grates exit the crusher. This process ensures consistent output size and prepares the materials for subsequent processing or use.

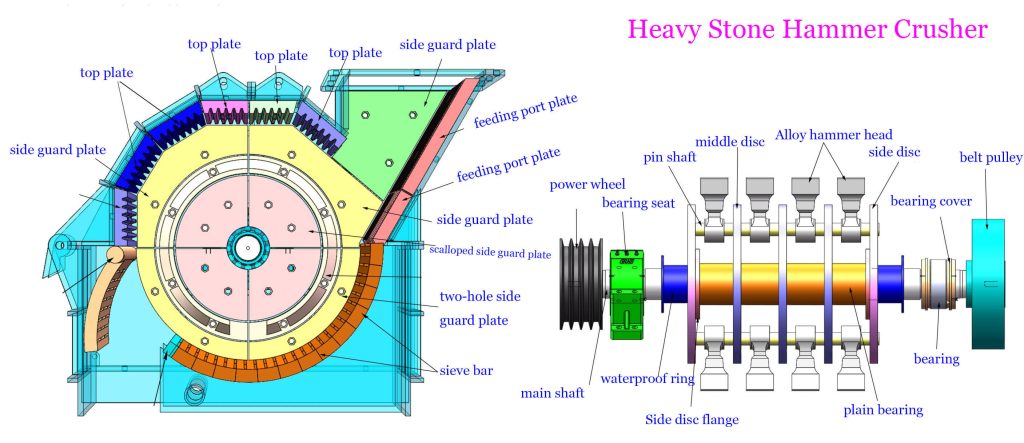

Key Components of a Hammer Crusher

Hammers and their impact function

Hammers are the primary tools in a hammer crusher. These components strike materials with high force to break them into smaller pieces. Each hammer is mounted on the rotor and rotates at high speed. The design of the hammers determines their efficiency in crushing. Some hammers feature wear-resistant materials to extend their lifespan. Regular inspection ensures that worn hammers are replaced promptly. Proper maintenance of hammers enhances the crusher’s performance and ensures consistent material output.

Rotor and its role in generating force

The rotor is the central part of the hammer crusher. It holds the hammers and spins at high speeds to generate the impact force needed for crushing. The rotor’s balance is critical for smooth operation. An imbalanced rotor can cause vibrations and reduce efficiency. Manufacturers design rotors to withstand the stress of continuous operation. Regular checks help maintain the rotor’s alignment and prevent damage to other components.

Grate bars for controlling material size

Grate bars are located at the bottom of the crushing chamber. These bars control the size of the material that exits the machine. Only particles small enough to pass through the gaps between the bars are discharged. Grate bars are adjustable, allowing operators to customize the output size. Proper alignment of the bars ensures uniform material size and prevents blockages. Regular cleaning of the grate bars keeps the crusher running efficiently.

Housing for protection and stability

The housing encloses the hammer crusher’s internal components. It protects the machine from external damage and ensures stability during operation. Manufacturers use durable materials to construct the housing, making it resistant to wear and tear. The housing also reduces noise and dust generated during crushing. Regular inspection of the housing prevents cracks or other structural issues that could affect performance.

Advantages of Hammer Crusher Machines

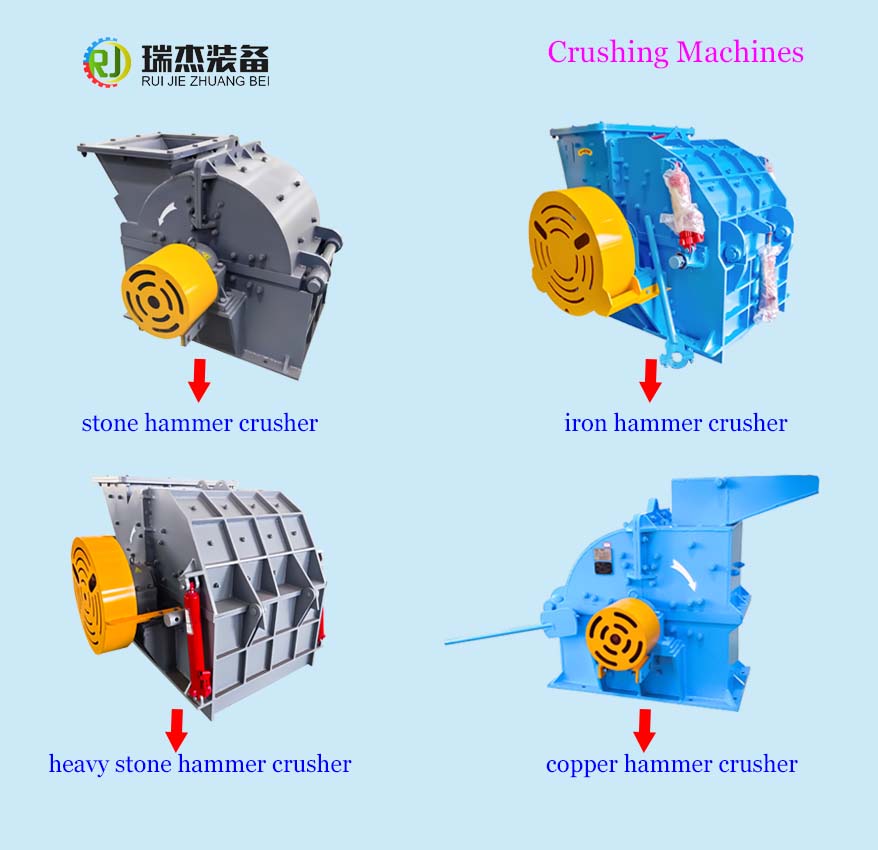

Common industries and materials it processes

A hammer crusher is a versatile machine used across multiple industries. Mining operations rely on it to crush ores and rocks into smaller sizes for further processing. In construction, it helps break down materials like limestone and concrete for use in building projects.

Recycling facilities use this crusher to process waste materials such as glass and ceramics, turning them into reusable forms. Its ability to handle brittle and medium-hard materials makes it a valuable tool in these industries.

Benefits of impact-based crushing

Impact-based crushing offers several advantages over other methods. The hammer crusher uses high-speed hammers to apply force directly to the material, ensuring efficient size reduction. This method produces uniform particle sizes, which simplifies subsequent processing.

The design minimizes energy consumption while maximizing output. Additionally, impact-based crushing reduces the need for secondary crushers, saving time and resources.

Cost efficiency and productivity improvements

The hammer crusher delivers significant cost savings for businesses. Its simple design and fewer moving parts reduce maintenance expenses. Operators can adjust the machine to produce specific material sizes, improving productivity.

The crusher’s high-speed operation ensures faster processing, which increases overall output. These features make it an economical choice for industries seeking to optimize their operations.

Maintenance Tips for Optimal Performance

Regular inspection and part replacement

Regular inspections are essential for maintaining the performance of a hammer crusher. Operators should examine critical components like hammers, rotors, and grate bars for signs of wear or damage. Worn-out parts reduce the machine’s efficiency and may lead to unexpected breakdowns.

Replacing these parts promptly ensures smooth operation and prevents further damage to other components. A scheduled maintenance routine helps identify potential issues early, minimizing downtime and extending the crusher’s lifespan.

Proper lubrication of moving parts

Lubrication plays a vital role in keeping the crusher’s moving parts in optimal condition. Components like the rotor and bearings require consistent lubrication to reduce friction and prevent overheating. Operators should use the recommended type of lubricant and apply it at regular intervals.

Neglecting lubrication can lead to increased wear and tear, affecting the machine’s performance. A well-lubricated crusher operates more efficiently and delivers consistent results over time.

Avoiding blockages through correct material feeding

Blockages can disrupt the operation of a hammer crusher and reduce its performance. Feeding the machine with materials of appropriate size and consistency prevents such issues. Operators should avoid overloading the crusher, as this can strain its components and cause jams.

Using a steady and controlled feeding system ensures smooth material flow and enhances the machine’s efficiency. Proper feeding practices not only improve performance but also reduce the risk of damage to internal parts.

Conclusion

A hammer crusher provides an efficient solution for breaking down materials in industries like mining and construction. Understanding its components and working principle helps operators achieve better performance. Regular maintenance ensures the crusher operates smoothly and lasts longer. This machine remains a reliable choice for processing brittle materials effectively.