HeBei HuaiLai County IBA Sorting Plant Project

Our client’s project —HeBei HuaiLai County IBA Sorting Plant Project is located in Huailai County, Hebei Province, China, with a slag processing capacity of 540 T/D.The slag comes from the domestic waste incineration power plant, which is a kind of facility that converts domestic waste into electricity, which can effectively solve the problem of urban waste disposal and also provide renewable energy for the city.

However, during the operation of a domestic waste-to-energy plant, some slag is generated, which needs to be disposed of. This article will introduce the slag treatment or IBA sorting process of domestic waste-to-energy power plants, hoping to provide readers with reference.

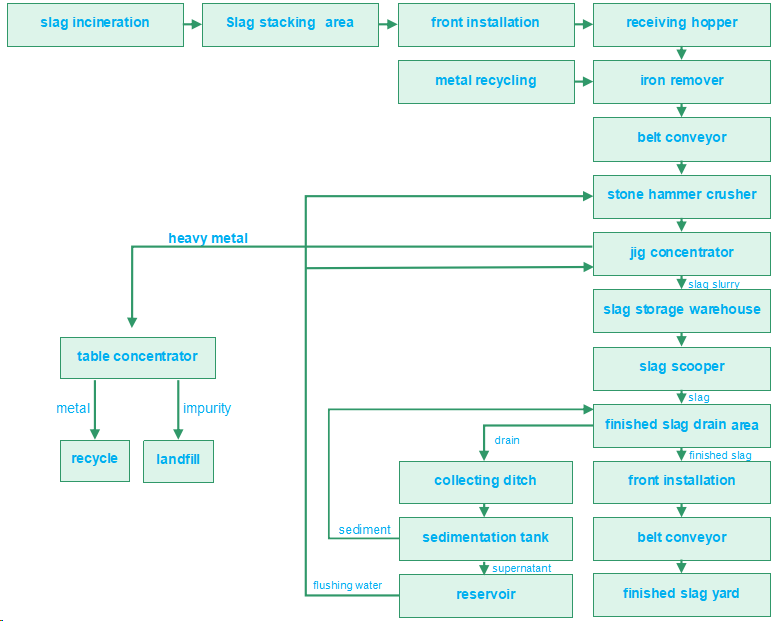

Incineration Bottom Ash Treatment (IBA Sorting) Process

Step 1: Reciprocating Feeder Feeds

The forklift shovels the incineration ash to the hopper, and the slag in the hopper flows to the Reciprocating Plate Feeder, and the machine pushes it to the conveyor belt for conveying to the next process.

Step 2: Sieving Through The Trommel Screen Equipment

Trommel Screen Machine sieves the slag blocks to obtain slag particles of different particle sizes.

Step 3: Crushing By Crushing Equipment

The Stone Hammer Crusher crushes the slag, and the particle size of the slag is reduced and crushed step by step to improve the metal separation rate.

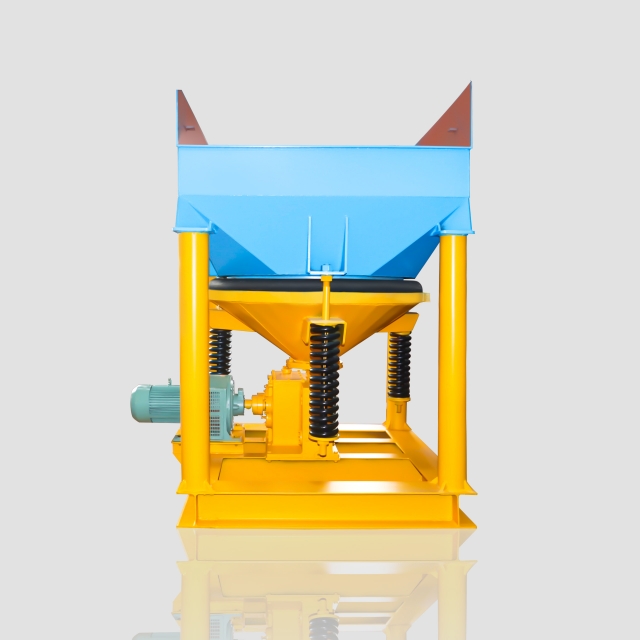

Step 4: Jig Machine re-separates Minerals

The difference between the specific gravity of the ore and the gangue is used for jigging sorting machine, and the Mineral Jig Separator separates the minerals with different specific gravity.

Step 5: Spiral Sand Washing Machine For Sand Washing

The Screw Sand Washing Machine washes the slag with water to remove the impurities covering the surface of the sand and gravel, making the slag more pure and more suitable for reuse.

Step 6: The Magnetic Separator Carries Out The Magnetic Material Sorting

The Eddy Current Separator and Magnetic Over-band Separator are used to sort and recover the aluminum, iron, copper and other metals in the slag.

Step 7: Dewatering Screen For Sand And Gravel Dewatering

Dewatering Vibrating Screens are used for water and sand separation, so as to facilitate sand preservation and water recycling.

Step 8: The Filter Press Carries Out Sediment Pressing

The sediment after precipitation is filtered by a filter press, and the clean water flows into the clear water pool for recycling, and the cement cake is discharged.

Step 9: Derive The Tailings

The slag is sorted and processed to produce eco-friendly sand, which can be sold for pavement materials or to make eco-friendly sand bricks.

Conclusion

Every time we make scientific and technological innovation, it is not only an innovation of technology, but also a commitment to social responsibility. In the future, we expect that the resource treatment technology of waste incineration bottom ash can be an industry benchmark and achieve a win-win situation for the global environment and economy.

By the way, due to more and more urban waste producing everyday, if we choose the way to incinerate or landfill, that might cause a series of pollution problems. Therefor, it is necessary to adopt the innovation technology–artificial and intelligence sorting and recycling equipment to solve this kind of problem. For example, we can make full use of the eddy current separator to separate various nonferrous metal fragments such as aluminum, copper, silver from the solid waste/slag. We could aslso use the magnetic sorting machine for recycling IBA. IBA sorting is a good way to convert the waste into wealth. So, resources can be recycled, pollution can be reduced, at the same time, we can achieve the goal of protecting our environment, making our earth more sustainable.