Guangxi LuChuan Incineration Bottom Ash (IBA) Sortng Plant

This project of our client is located in Luchuan County, Guangxi. The incineration bottom ash(IBA) sorting plant project took 1 year to complete, from plant design, machine manufacturing, installation, commissioning, operation. It was officially put into trial operation in May this year. The daily processing capacity of IBA is 650T/D.

Below are the pictures of our projects from plant design to installation and commissioning

So do you know what incineration bottom ash (IBA) is used for? Below I will explain to you the value of incineration bottom ash (IBA).

Uses of Incineration Bottom Ash (IBA)

Incineration ash has a variety of uses, mainly including building materials and inorganic polymeric materials.

Incineration bottom ash, especially the residue produced by municipal solid waste incineration treatment plants, is mainly composed of two parts: the slag produced by the incinerator and the fly ash collected by the dust collector.

These incineration ash slags contain a certain amount of heavy metal substances, which may cause pollution to the environment if not properly disposed of. However, incineration residues can also be used effectively and have certain environmental and economic value.

Making Building Materials: Incineration residues can be used as a raw material for building materials such as light aggregates, floor tiles, wall tiles, etc. This utilization method not only helps to reduce the consumption of natural resources, but also replaces traditional building fillers to a certain extent, which has great market potential.

Production of Inorganic Polymeric Materials: Studies have shown that inorganic polymeric materials can be made from coal-fired bottom ash. This material has the dual advantages of environmental protection and resource reuse, which is of great significance for promoting sustainable development.

Through the above uses, the incineration of bottom ash not only realizes the resource utilization of waste, but also helps to reduce environmental pollution and promote the development of circular economy.

What Does Incineration Bottom Ash Consist Of ?

Incineration bottom ash is mainly composed of burned ash and unburned residual organic matter. Incineration bottom ash, also known as bottom ash, is the discharge of unburned residues from the end of the hearth during waste incineration.

These residues mainly consist of ash after combustion as well as incompletely burned organic matter.

How to Dispose Of Incineration Bottom Ash?

Resource Utilization: Although there are heavy metals in the bottom slag, it can be stabilized to a certain extent after the high-temperature incineration process.

The main components of the bottom slag are ash, stones, glass, ceramics and metals, etc., and Germany, Switzerland, the Netherlands and other countries have recycled iron, aluminum, zinc and other metals in the bottom slag.

In the European Union, except for Switzerland, which classifies the bottom slag as a reactive substance, the treated bottom slag is used in road subgrade materials, noise reduction walls, internal substrates for embankment construction or aggregates for cement production, as well as in the production of pavement bricks and tiles.

Safe Disposal: For the bottom ash that cannot be recycled, developed countries mainly use the method of “stabilization and solidification + landfill” to dispose of it.

For example, the United States, Canada and EU countries other than Germany dispose of incineration bottom ash in this way. In Switzerland, the metals in fly ash are separated and extracted before being land-filled.

The following video is the wet separation of various non-ferrous metals from the incineration bottom ash by our customer, which has achieved the maximum recovery rate, and the customer is very satisfied

Aluminum Metal

Copper Metal-copper ore

Incineration Bottom Ash –Big Copper

Conclusion

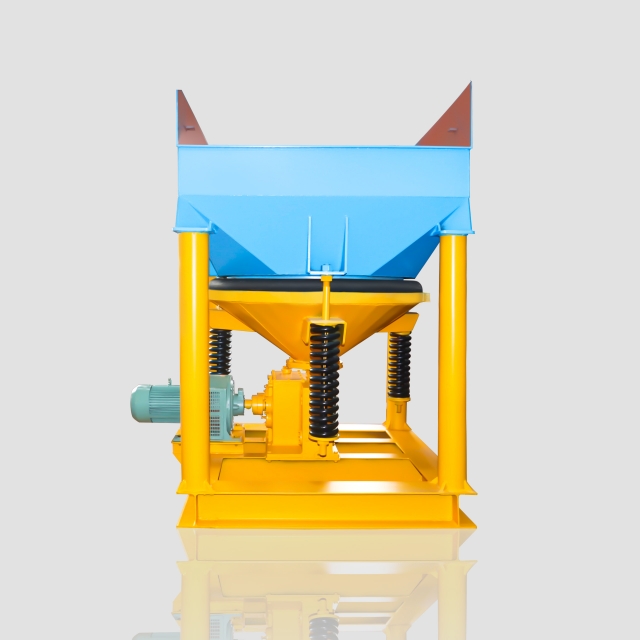

For incineration ash separation technology, whether you want wet separation or dry separation, we can meet your needs and design the best quality recycling and sorting solutions for you.

Our dry sorting is slightly more than wet sorting abroad, and one of our customers in Thailand uses wet sorting technology, because wet sorting technology has a higher recovery rate than dry separation, which is conducive to the purification and separation of small amounts of gold metal. In addition, wet sorting is conducive to the protection of the environment and the emission of no air pollutants.