Incineration Bottom Ash (IBA) Sorting Plant Project Introduction

Our Incineration Bottom Ash (IBA) Sorting plant is located in Beihai City, GuangXi. With a total area of 27,400.49 square meters (about 41.4 acres), it is located in Daxin Village, Wujia Town, Hepu County, Beihai City.

The total investment of the project is 60 million CNY. The Municipal solid Waste incinerator Bottom Ash (IBA) sorting plant was officially put into use in March 2023

Bottom ash (IBA) left over from the incineration of waste in power plants can be treated and recycled into materials suitable for construction projects, as well as raw materials for roads and asphalt. We can separate various non-ferrous metals such as iron, aluminum, copper, copper grit and so on from the slag.

Then these various metals that are sorted out will be bought by a special resource recovery company, and we can sell them to the resource recovery company to make a profit.

We can achieve 100% full utilization of the material, and finally sort, wash out the sand, which can be used in the construction industry and cement mixing plant.

Now we divide the aggregate into coarse aggregate and fine aggregate through related processes, among which coarse aggregate is used in concrete batching plant, as one of the raw materials for low standard concrete, fine aggregate can be used for the molding of brick products, used in municipal, garden, water conservancy, etc.

Incineration Bottom Ash (IBA) Sorting Process

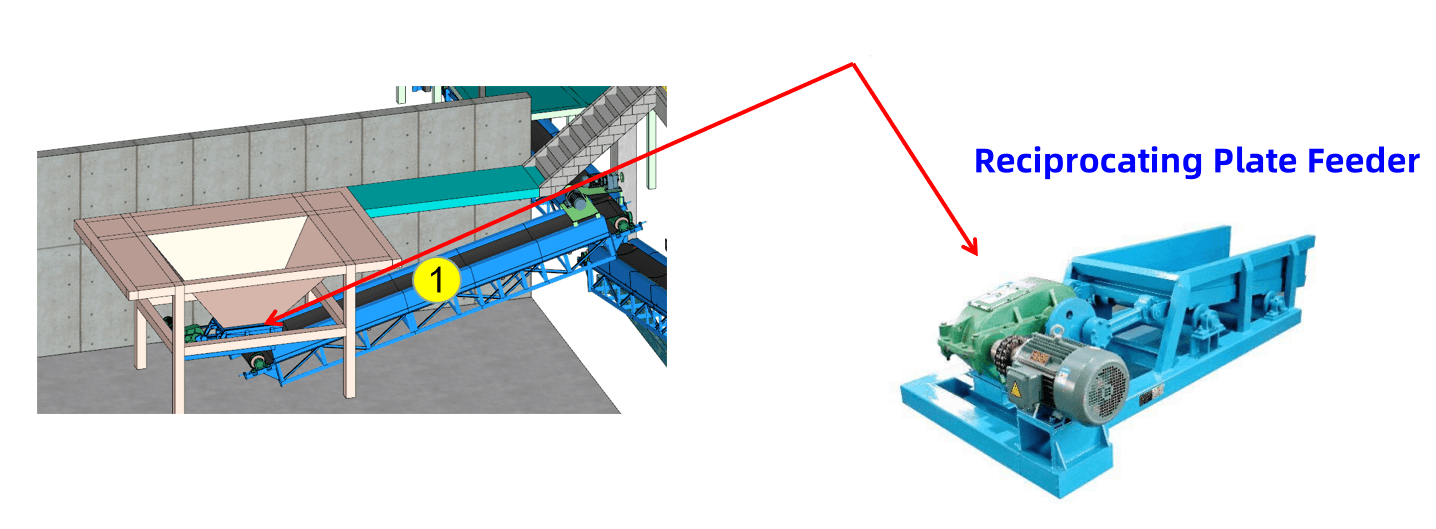

Process: 1. Load Material

Product Use:The material flowing down the hopper is transported to the No. 1 conveyor belt through the Reciprocating Plate Feeder.

Features: uniform feed, adjustable feed amount, small shape height, simple structure, reliable work, strong material adaptability, large conveying capacity, multi-stop feed amount adjustment, wear-resistant products, while avoiding the slag material has a long iron branch punctured the conveyor belt leading to scrap the conveyor belt

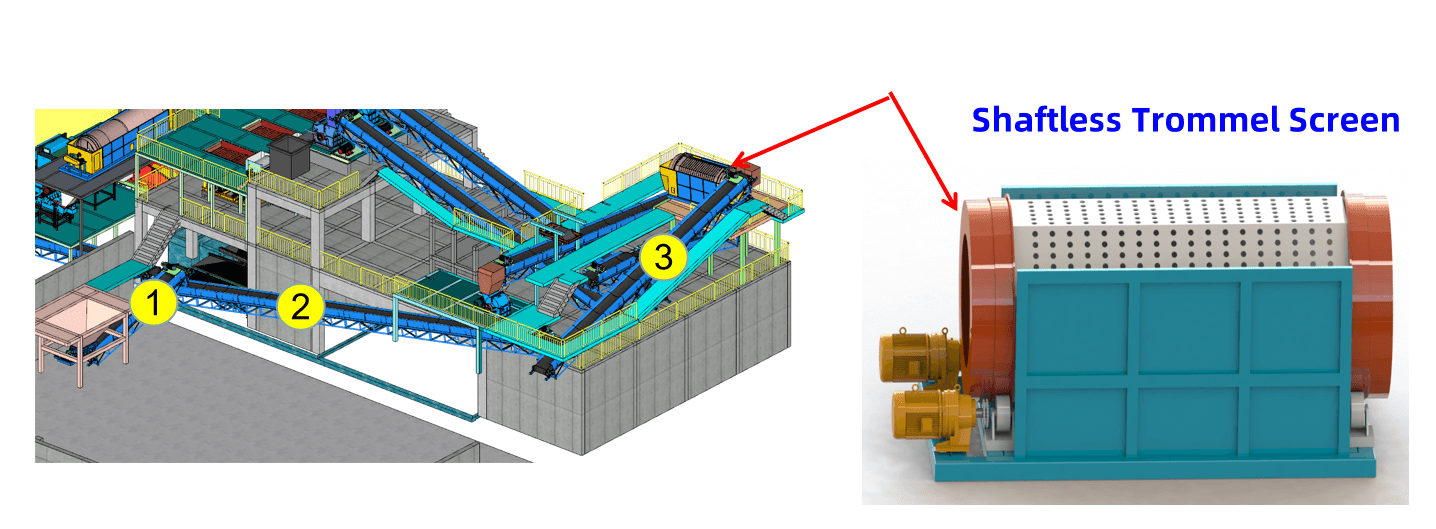

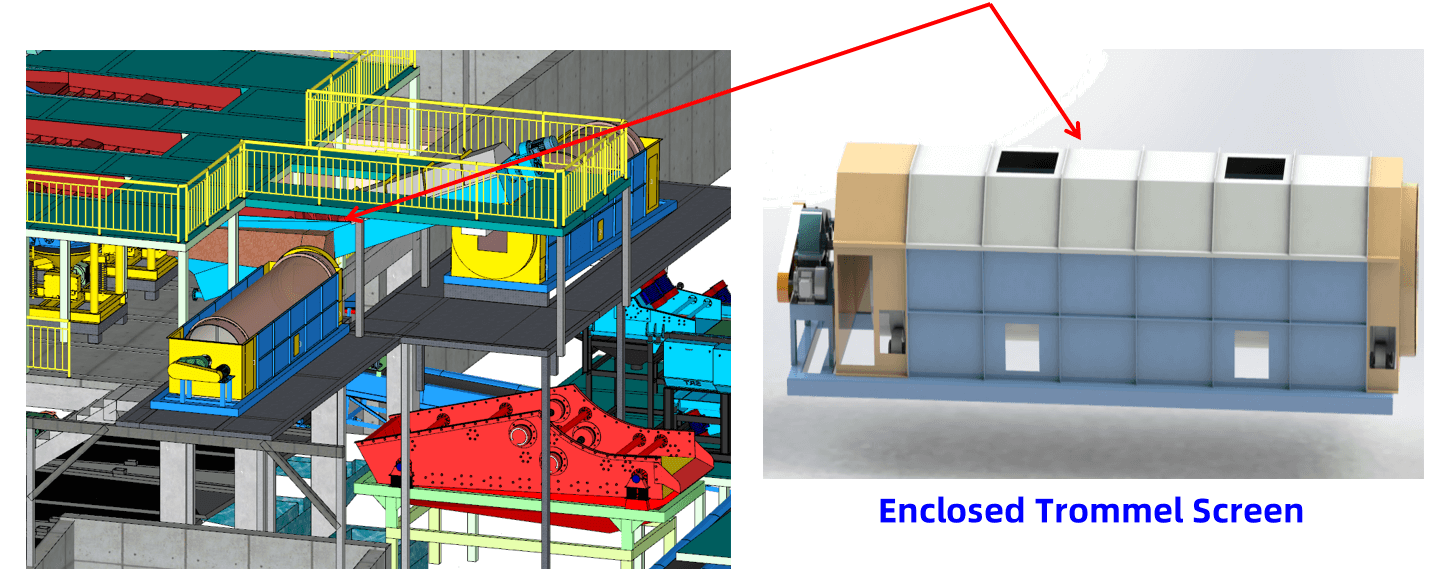

Process: 2. Screening of refuse and bulk materials

Product Use:The material is sent to the Shaftless Trommel Screen through the conveyor belt No. 1, 2 and 3, and the drum screen classifies the particle size of the material and screens the unburned material.

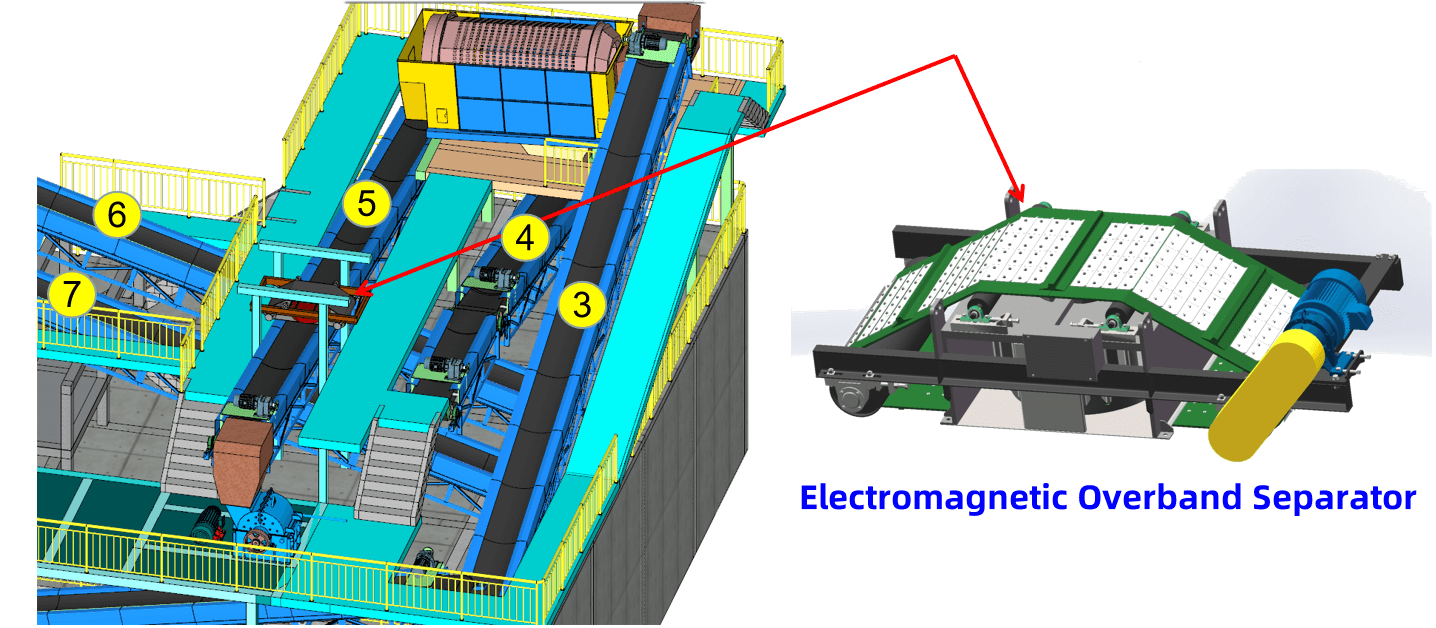

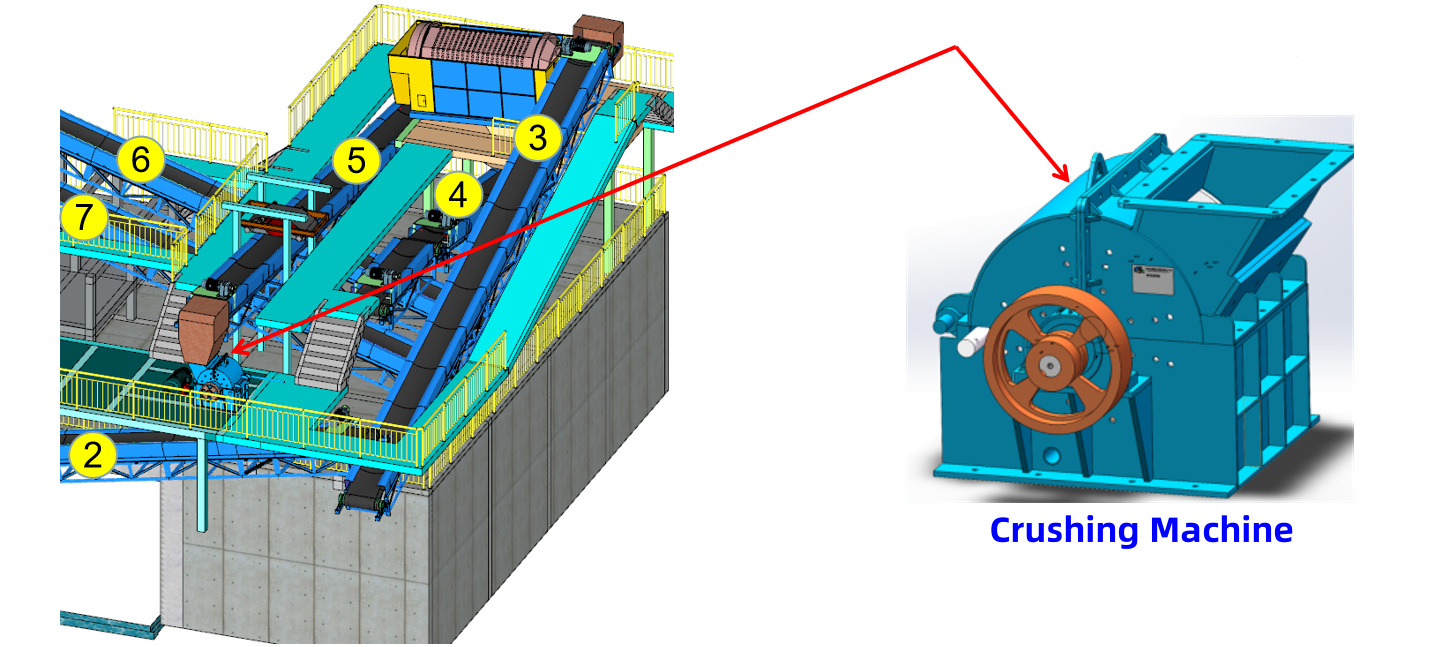

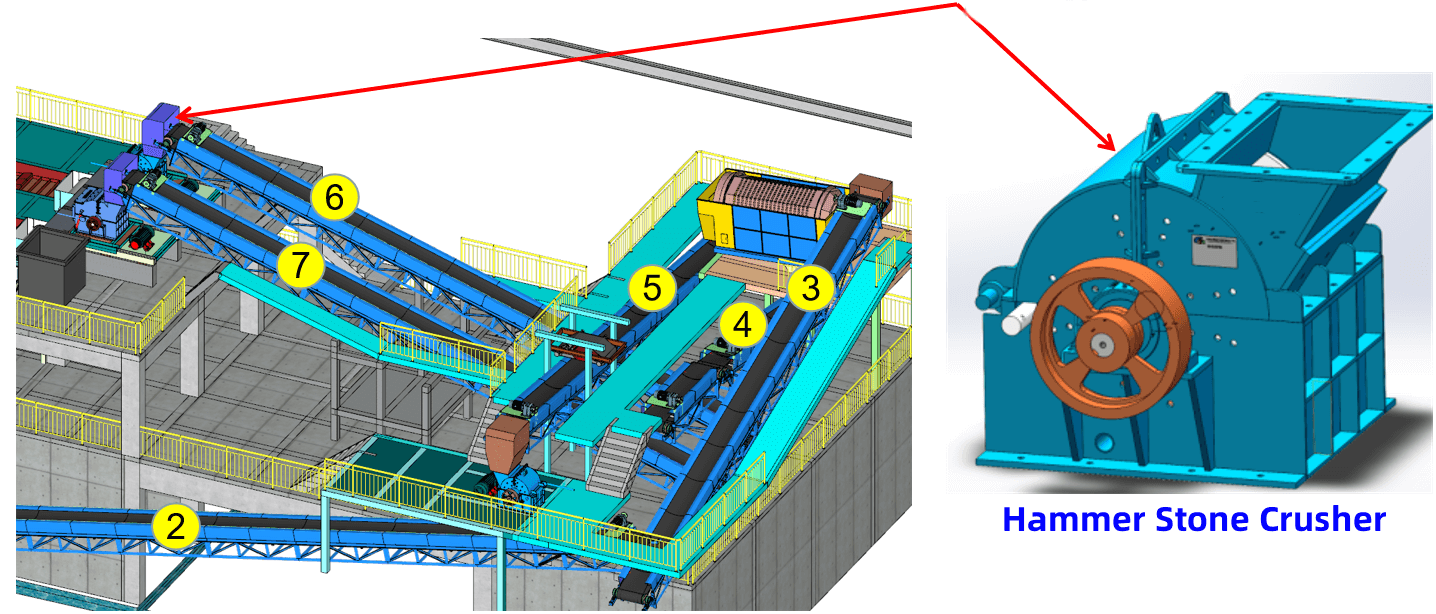

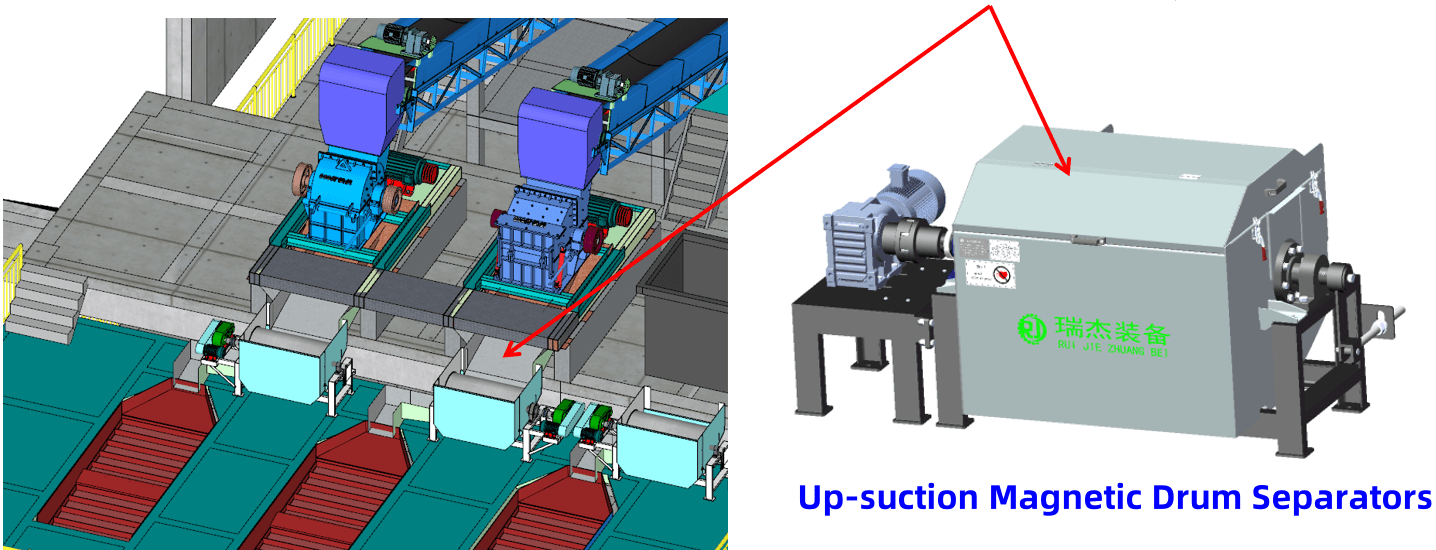

Process: 3-1. Conveyor belt material iron sand separation

Product Use:After screening, garbage and large materials pass through conveyor belt No. 5, some large iron is sucked up and dropped to conveyor belt No. 7 when electromagnetic hanging, and the remaining sand is returned to the crusher to break.

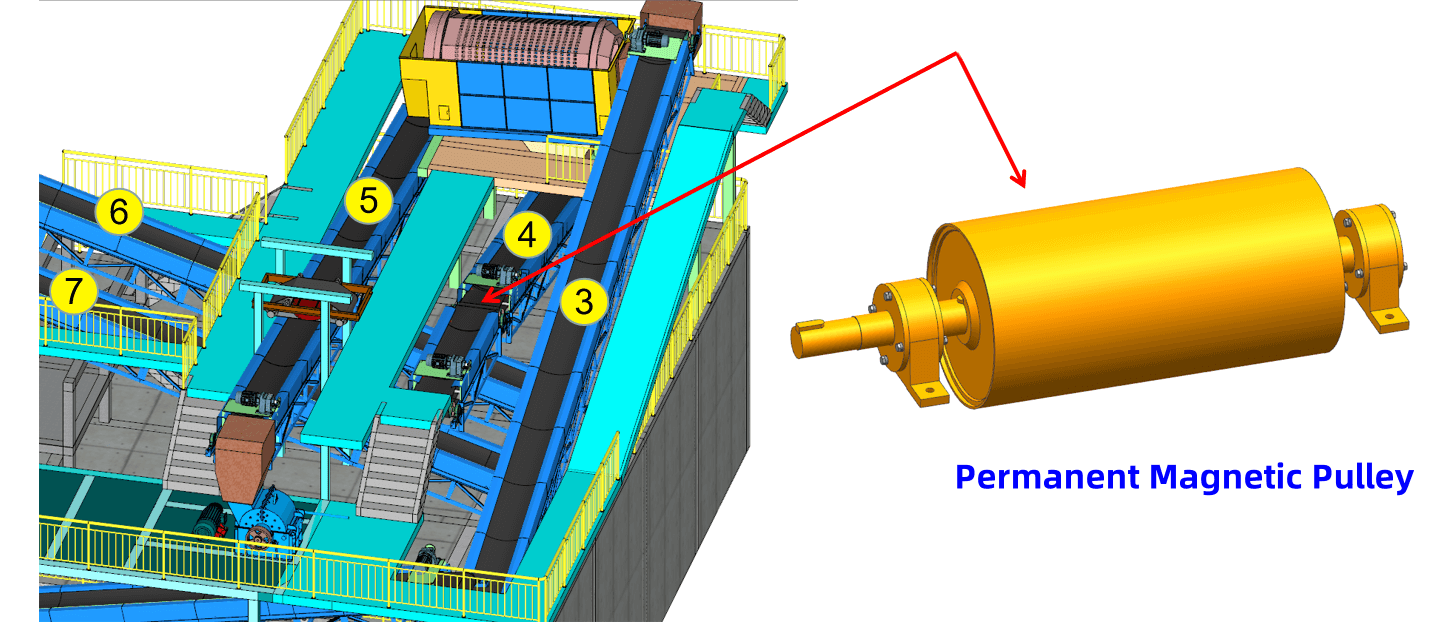

Process:3-2. Conveyor belt material iron sand separation

Product Use:After screening, part of the iron slag of the No. 2 conveyor belt material passes through the belt permanent magnet roller, and part of the iron is sucked into the belt and transported to the No. 7 belt.

Process: 4. Secondary Crushing

Product Use:After screening, materials with a diameter greater than 8cm are brought to the sand maker through conveyor belt No. 5 for crushing (back breaking) and then fall to conveyor belt No. 2 for re-loading.

Process: 5-1. Crushing (sanding)

Product Use:After screening, conveyor belt No. 6 transmits the sand material to the sand making machine, and the material is more refined and broken, which requires flushing.

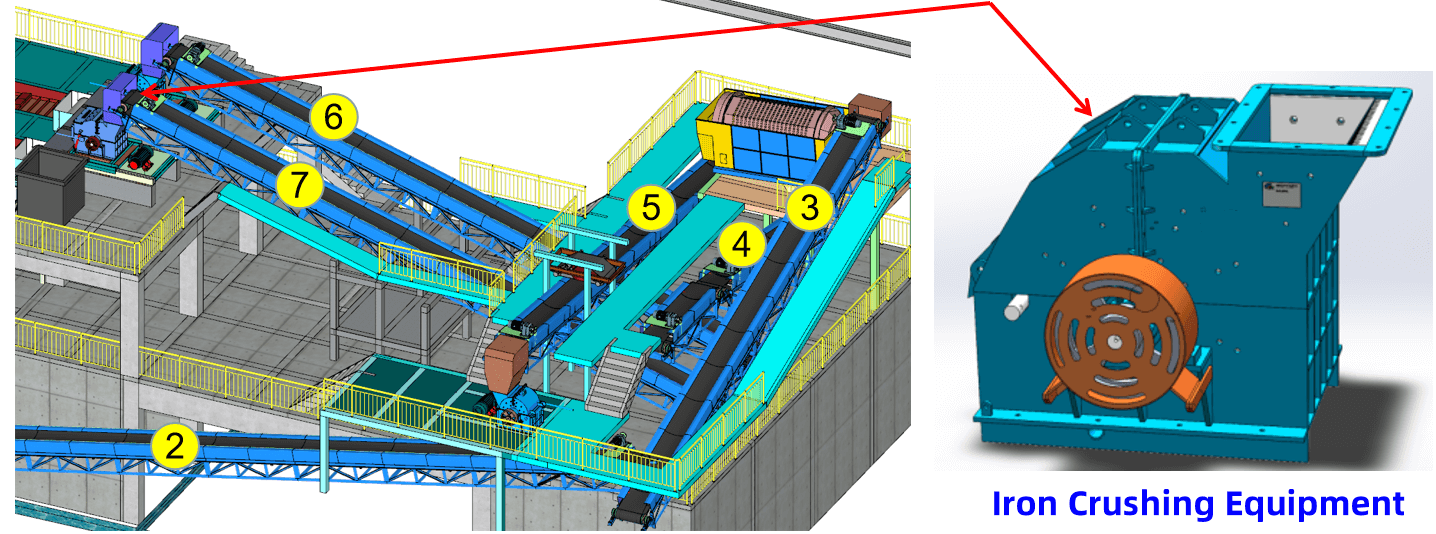

Process: 5-1. Crushing (Forge Iron)

Product Use:After screening, conveyor belt No. 6 delivers the iron material to the iron crushing equipment to break the material more finely, which requires flushing.

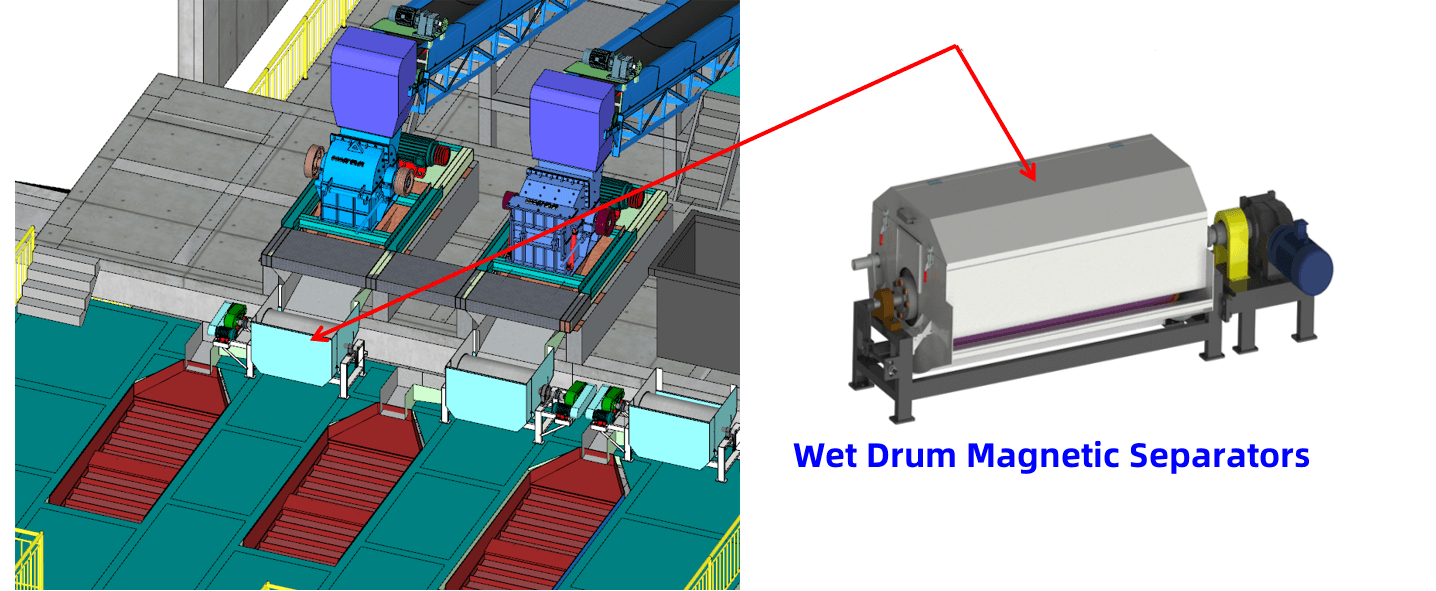

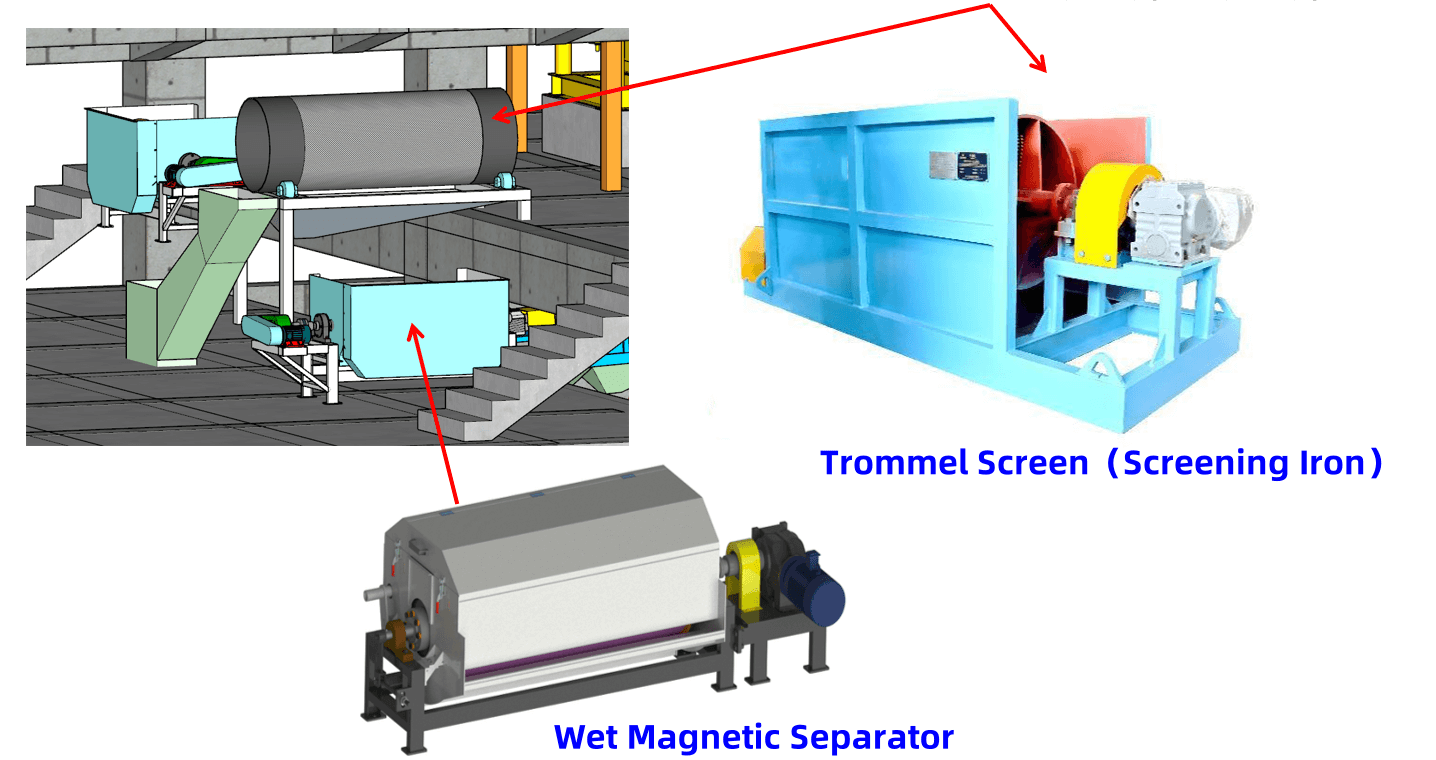

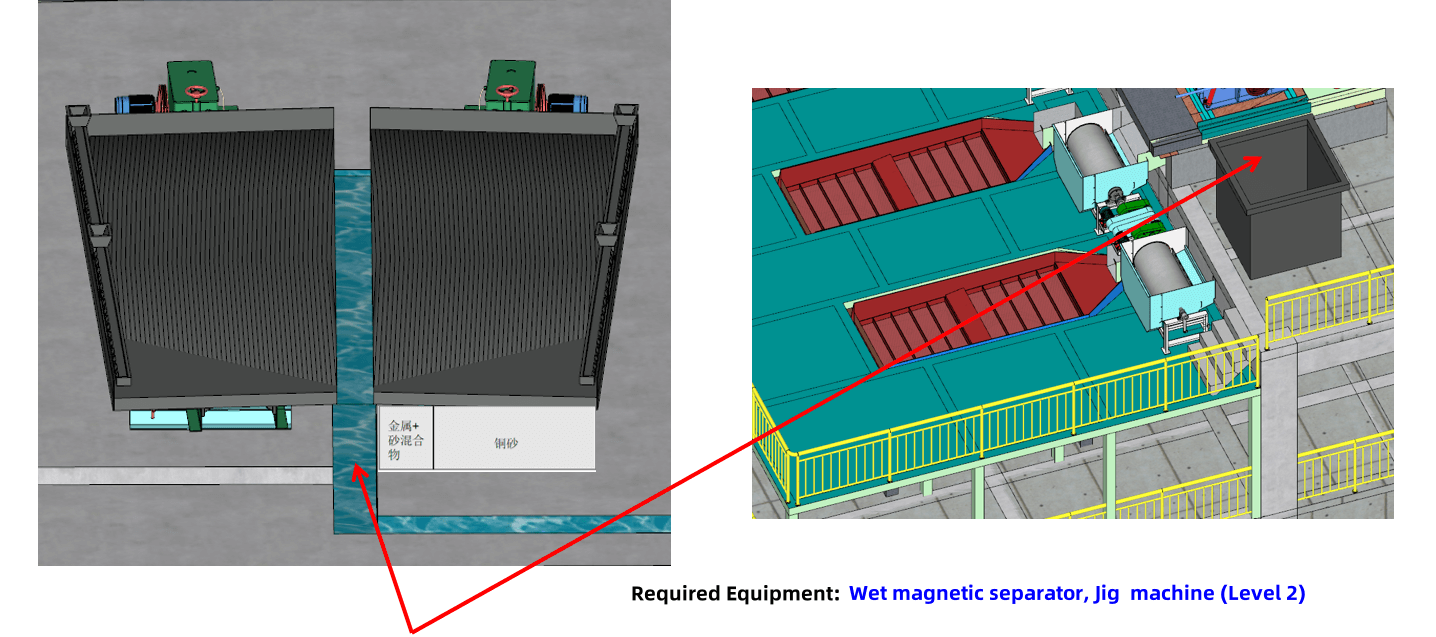

Process: 6-1. Iron is separated from slag

Product Use:After the material is broken, it flows into the wet magnetic separator, and the iron and slag are separated by the magnetic separator into the roller screen.

Process: 6-2. Iron is separated from slag

Product Use:Iron slag suction on the material after broken into magnetic separator, after magnetic separator separation of iron and slag, iron material into the drum screen.

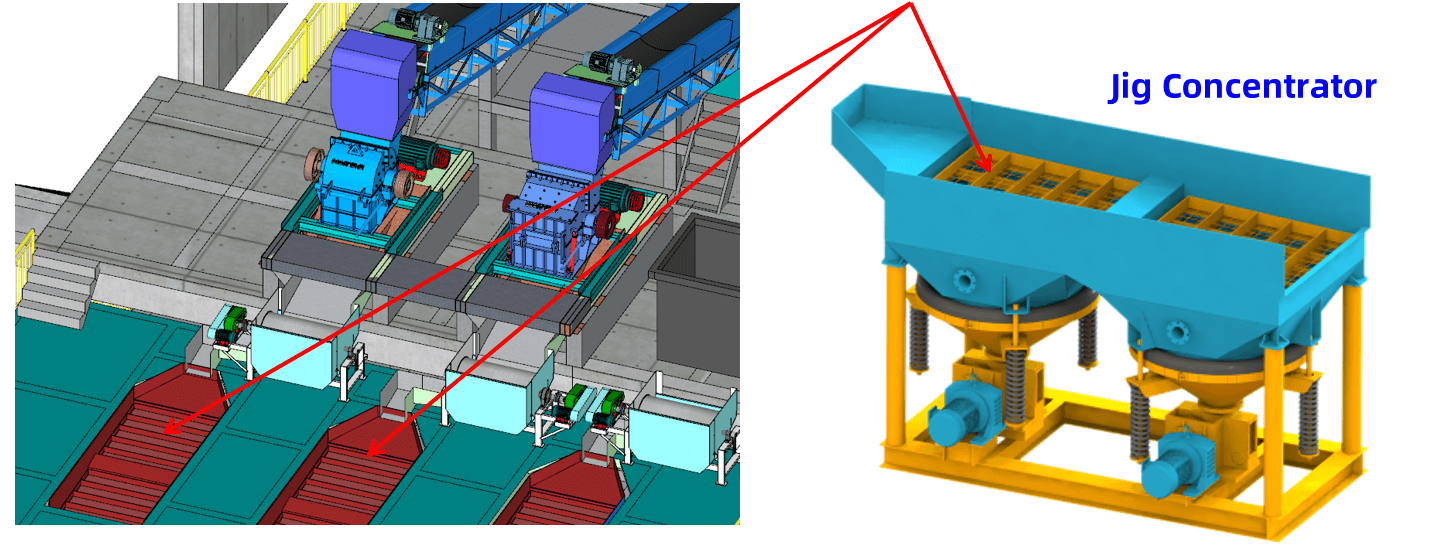

Process: 7.Gravity sorting(jig machine)

Product Use:After magnetic separation, the residual slag flows into the jig, the jig floats up and down, the dense metal material sinks, and the small density material sand and some non-ferrous metals flow above.

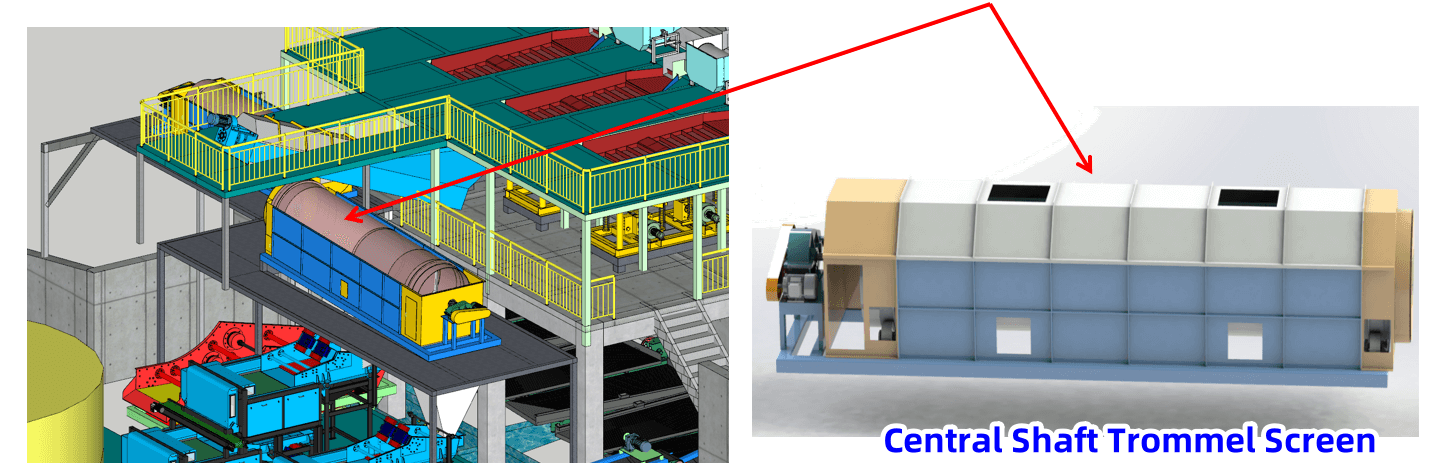

Process: 8.Screening of iron slag

Product Use:The iron slag selected by the magnetic separator is sifted through the Trommel Screen Machine, the large iron and iron powder are sifted, the iron powder is sifted into the magnetic separator again, and the iron slag material flows into the shaker after the different sizes of iron enter the different magnetic separators.

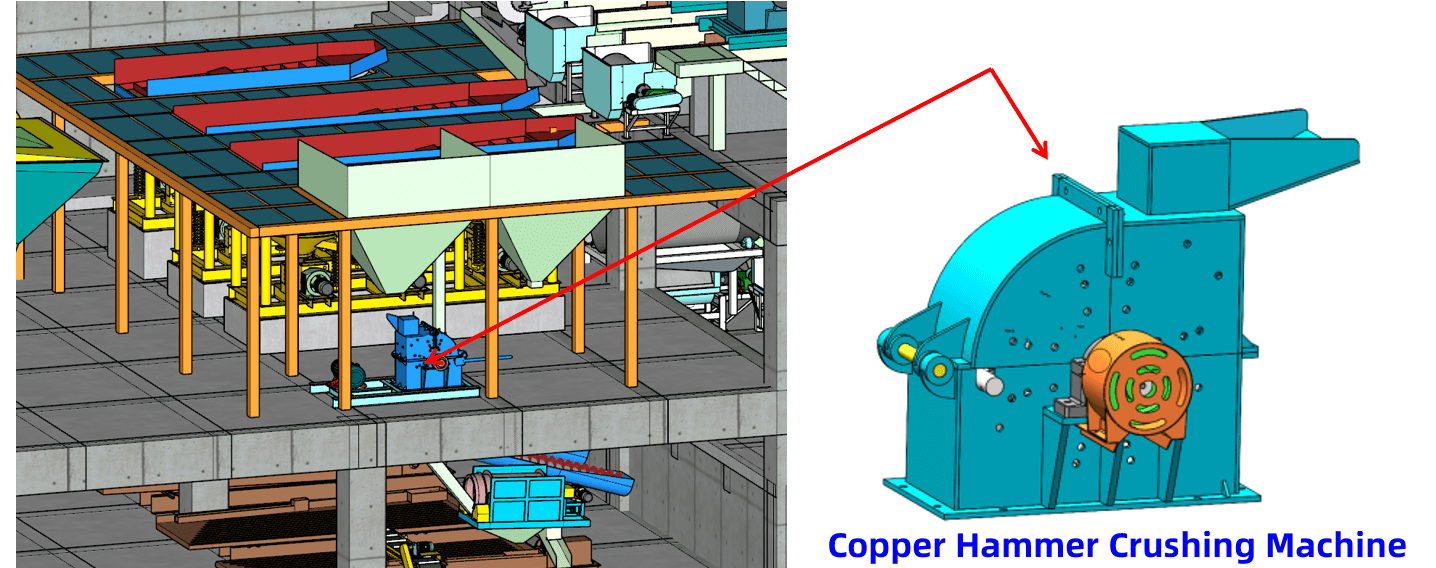

Process: 9.Copper Hammer Crushing Machine(Crushed material)

Product Use:After the material passes through the jig machine, the material with large density and volume is sunk in the upper tank of the screen, and the material flows into the copper head machine for crushing.

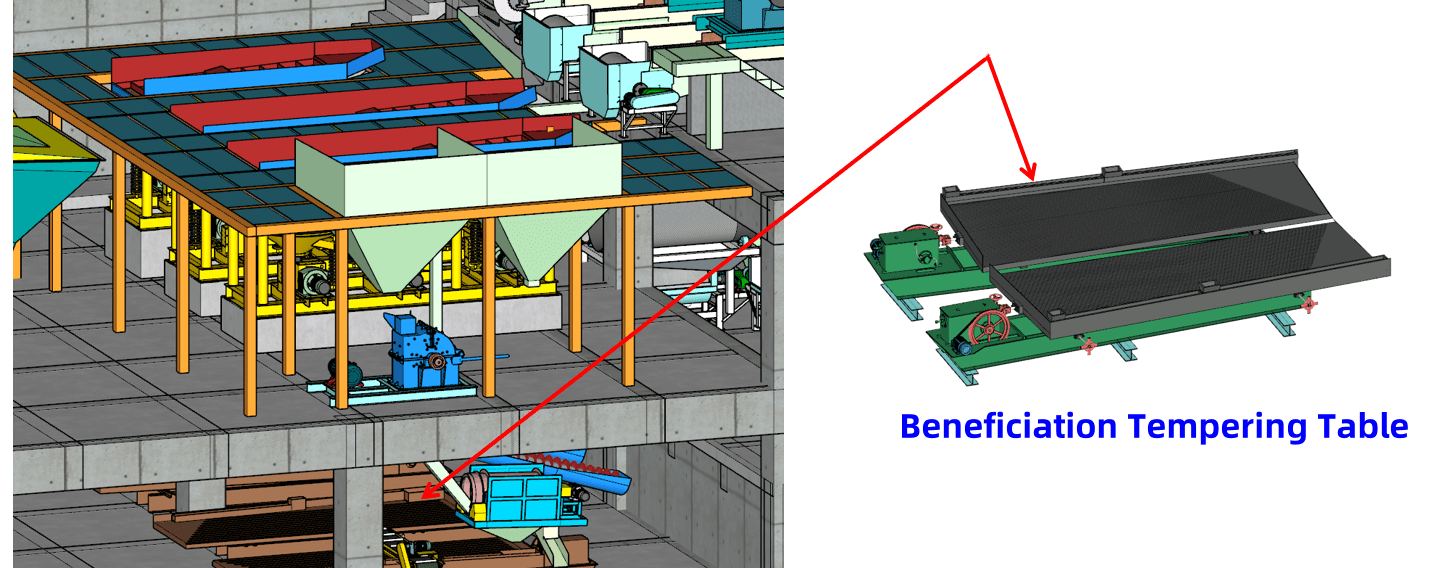

Process: 10.Tempering table sorting

Product Use:After the material passes through the jig, the density is large and the volume is less than 2mm, and the precipitation falls into the jig hole, and the jig funnel directly flows into the shaker.

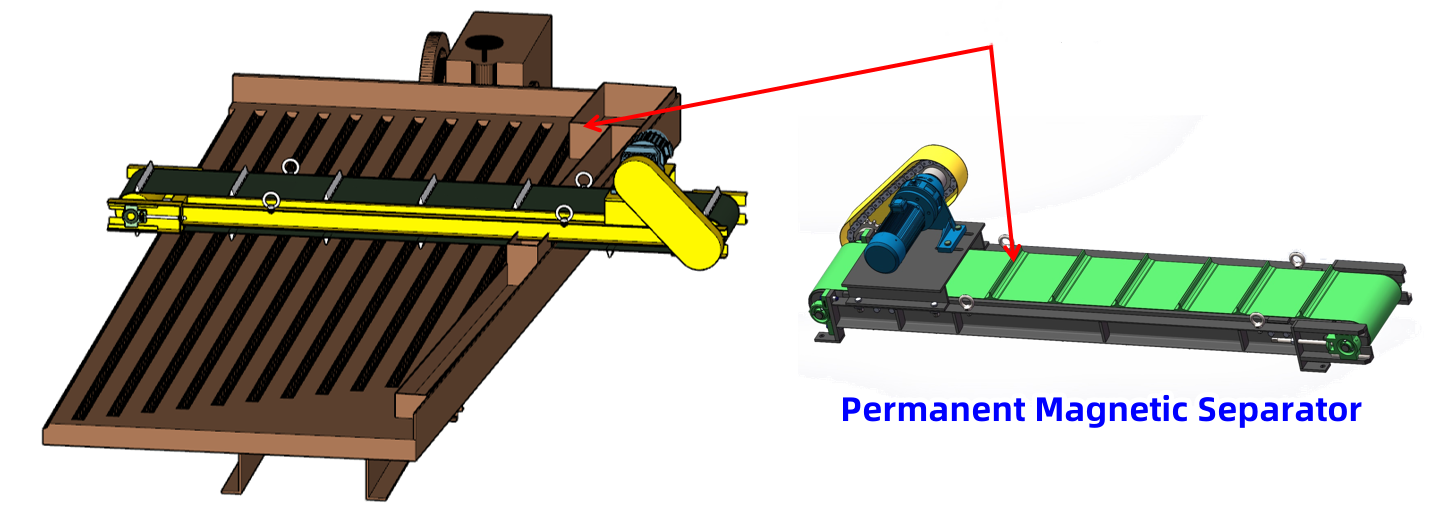

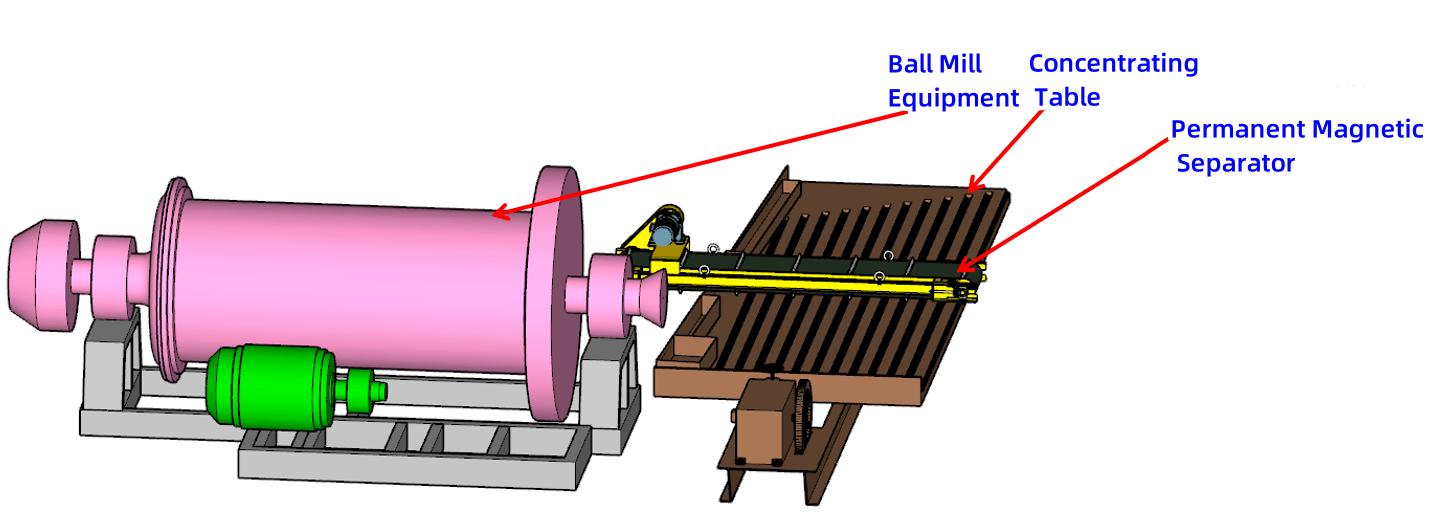

Process: 11.Permanent Magnetic Separator-Sorting iron filings

Product Use:There are some iron powder in the material through the shaking table, and the magnetic sorting machine is hung on the beneficiation shaking table to sort out the iron powder in the material flowing through.The sand part of the shaker flows into the sand tank, the copper sand part flows into the copper sand barrel, and the metal and sand mixture part flows into the ball mill.

Process: 12.Shaker effluent sand material treatment

Product Use:The sand material screened by the shaker flows into the sand collection tank, enters the sand tank and pumps into the sand cylinder of the machine, re-enters the wet magnetic separator, and then enters the secondary jig machine.

Process: 13.Permanent Magnetic Separator removes iron

Product Use:The sand material screened by the shaker flows into the sand collection tank, enters the sand tank and pumps into the sand cylinder of the machine, re-enters the wet magnetic separator, and then enters the secondary jig machine.

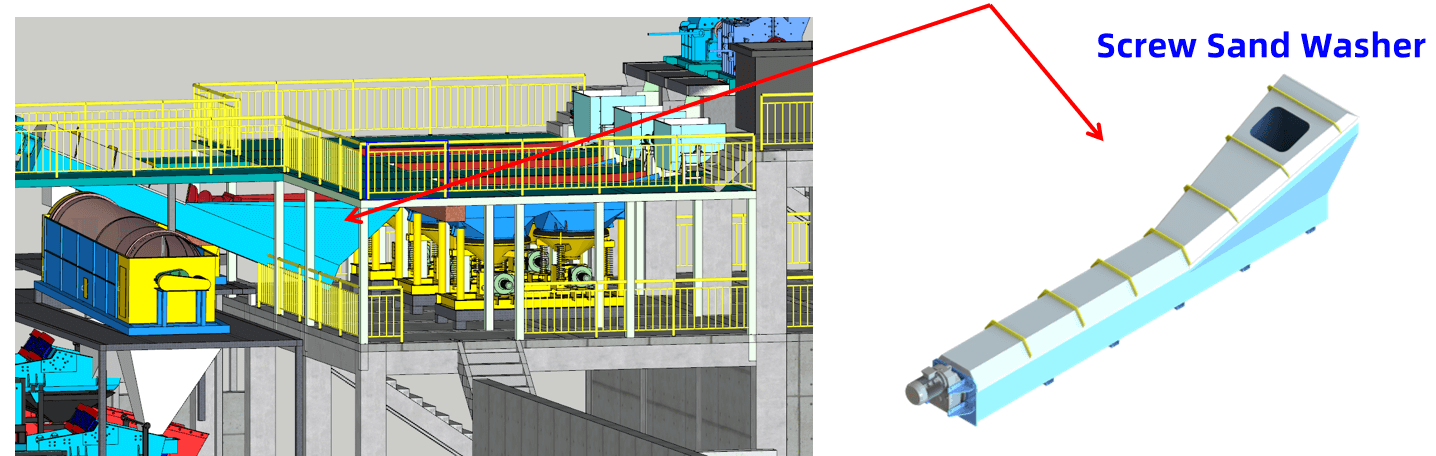

Process: 14.Auger Delivery

Product Use:The material passes through the jig, and the laminar flow on the material with low density passes along the flow and enters the spiral sand washing machine.

Process: 15.Floating material handling

Product Use:The spiral flotsam flows through the tank to the floating sieve dragon, the sand water part flows into the sand tank through the sieve dragon, and the flotsam enters the garbage pond.

Process: 16.Floating material handling

Product Use:The precipitated material is pushed by screw conveyor to the grading drum screen.

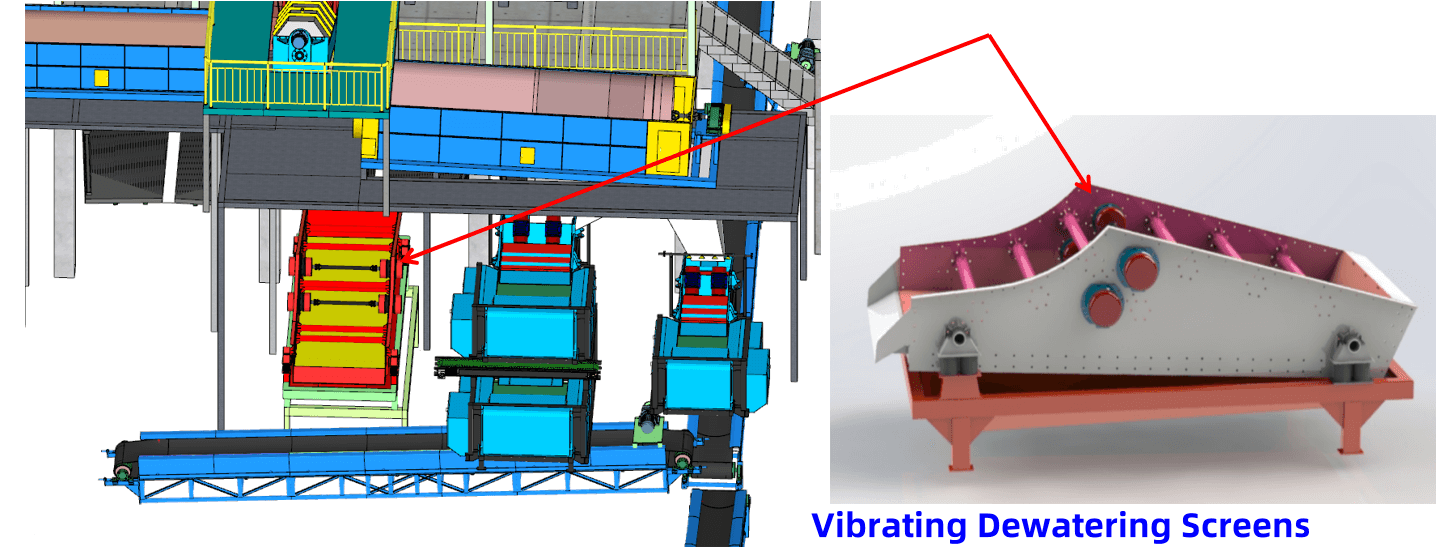

Process: 17.Screening of materials below 2.5mm by grading drum

Product Use:The material (sand) passes through the grading drum sieve and the material below 2.5mm enters the dewatering sieve. After dewatering through the dewatering sieve, the conveyor belt on the material directly enters the recycling environmental protection sand bin.

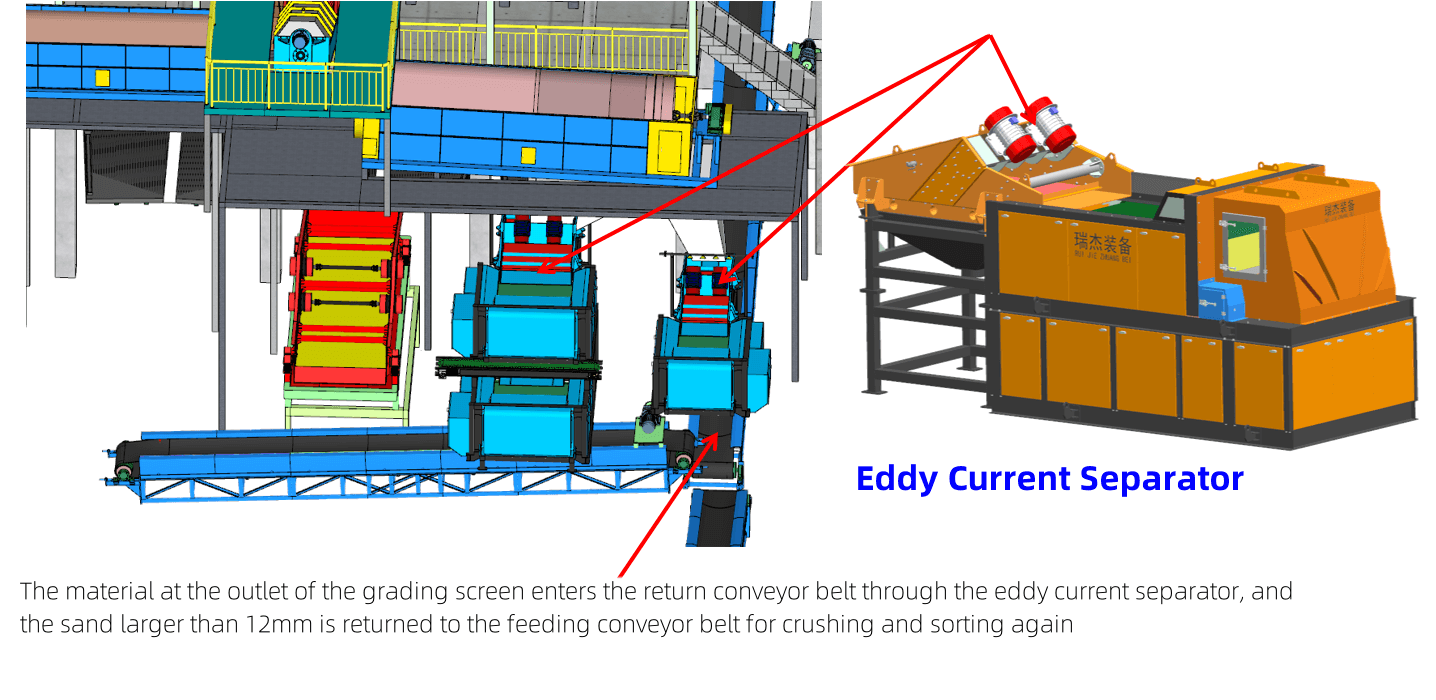

Process: 18.The grading drum screens and sorts 3-12mm materials

Product Use:The material is screened 3-12mm by the grading screen cage into the eddy current sorting machine, and the eddy current sorting machine (jump aluminum machine) sorts the metal aluminum material. Aluminum material recycling, sand into environmental protection sand warehouse.

Supporting Power Plant Data

| Supporting Power Plant | Beihai Beikong Environmental Technology Development Co., Ltd |

| Power Plant Scale | Waste incineration volume 1400 tons/day |

| Construction and Processing Scale of Slag Plan | 1000 tons/8 hours |

| Power Plant Slag Volume | 420 tons/8 hours |

Conclusion

The project directly solves the problem of comprehensive utilization of slag in Beihai domestic waste incineration power plant, and at the same time solves the problem of slag landfill or random stacking, occupying valuable land resources and causing secondary pollution.

Therefore, the construction of this project is based on the long-term development of the enterprise and the harmony and unity of environmental protection, in line with the concept of circular economy, and is an investment project to improve the social environment, which plays an important role in saving land resources, protecting the environment and promoting the stable development of enterprises.