What are the benefits of using an automatic oil injection system in efficient eddy current sorting machines?

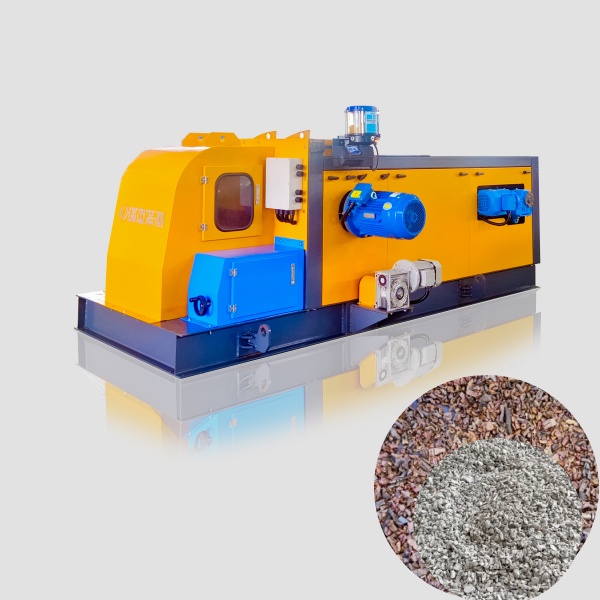

In the modern industrial field, eddy current sorting machines(ECSMs) are playing an increasingly important role as efficient renewable resource recovery equipment. In order to further improve its performance and reliability, automatic oil injection systems are widely used in eddy current sorting machines. This innovative technology has brought many significant benefits and new development opportunities for the resource recycling industry.Now let me introduce the benefits of using an automatic oil injection system for efficient eddy current sorting machines?

Improve equipment operating efficiency

During the long-term operation of the eddy current separator, each key part needs to be kept in a good lubrication state to ensure the normal operation of the equipment. The automatic oil injection system can provide lubricating oil to equipment in a timed and quantitative manner, avoiding equipment wear and failure caused by untimely or inaccurate manual oil injection. Through continuous lubrication, the equipment operates more frequently, reducing frictional resistance, thereby improving the operating efficiency of the equipment. This means that in the same cycle, the eddy current sorting machine can handle more orders, bringing higher production efficiency to the enterprise.

Extend the service life of efficient eddy current sorting machine

The wear and tear of efficient eddy current sorting machine is one of the main factors affecting its service life. The automatic oil filling system can accurately control the supply of lubricating oil to ensure that each key part receives the appropriate amount of lubrication. This not only reduces friction and wear between equipment components, but also reduces the heat and noise generated by wear. At the same time, good lubrication can also prevent metal parts from rusting and corroding, further extending the service life of the equipment. For enterprises, this means reduced equipment update and maintenance costs and increased return on investment.

Reduce maintenance costs

The traditional manual oiling method requires a lot of manpower and time, and is prone to problems such as uneven oiling and omissions. The automatic oil filling system completely avoids these problems. It can automatically complete the oil injection process without manual intervention. This not only saves labor costs, but also improves the accuracy and reliability of oil injection. In addition, the automatic oil injection system can also monitor the lubrication status of the equipment in real time, and issue an alarm in a timely manner when abnormal situations occur, reminding maintenance personnel to handle them. This can avoid serious equipment failures due to poor lubrication and reduce maintenance costs and downtime.

Improve device security

During the operation of the efficient eddy current sorting machine, if the high-speed rotating components lack good lubrication, they are prone to safety hazards such as overheating and jamming. The automatic lubrication system can ensure that the equipment always maintains a good lubrication state, reducing these safety risks. At the same time, the automatic oil injection system can also reduce the static electricity generated by equipment due to friction, avoiding fire and explosion accidents caused by static electricity. This is of great significance for ensuring the safety production of enterprises.

Adapt to harsh working environments

In some harsh working environments, such as high temperature, high humidity, and high dust, manual oiling becomes more difficult and dangerous. The automatic oil injection system of eddy current sorting machine can work normally in these harsh environments, providing stable lubrication for the equipment. It is not affected by environmental factors and can ensure that the equipment can maintain good operating conditions under various complex working conditions. This provides a reliable guarantee for enterprises to use efficient eddy current sorting machines in different working environments.

Enhance the competitiveness of enterprises

With the increasingly fierce competition in the resource recycling industry, enterprises need to continuously improve their production efficiency and product quality in order to reduce costs and enhance competitiveness. The application of automatic oil injection system can significantly improve the performance and reliability of eddy current sorting machines, bringing higher production efficiency and better product quality to enterprises. This will help businesses stand out in market competition and win more customers and market share.

conclusion

The automatic oil injection system of RUIJIE efficient eddy current sorting machine has many benefits. It not only improves the operating efficiency and service life of the equipment, reduces maintenance costs and safety risks, but also adapts to harsh working environments and enhances the competitiveness of enterprises. With the continuous advancement of technology and the continuous promotion of applications, automatic oil injection systems will play an increasingly important role in the resource recycling industry, making greater contributions to promoting sustainable development.