Auto Shredder Residue (ASR) is the byproduct of shredding end-of-life vehicles, consisting of non-metallic materials like plastics, rubber, foam, and glass. These complex materials pose significant recycling challenges but also offer potential for repurposing into valuable resources through advanced sorting and processing technologies.

What is Auto Shredder Residue?

Auto Shredder Residue (ASR) refers to the non-metallic waste material generated during the shredding process of end-of-life vehicles (ELVs). When old cars and other vehicles are processed in a metal shredder, the metal parts are separated for recycling, while the remaining components make up the ASR. The composition of ASR includes a mixture of materials, each with different properties and recyclability potential.

The complex composition of auto shredder residue makes it difficult to sorting efficiently. Without proper processing, this material often ends up in landfills, contributing to environmental concerns. Technological advancements aim to make ASR recycling more efficient and sustainable, turning what was once waste into reusable resources.

Auto Shredder Residue Composition

Plastics

Plastics form a significant portion of auto shredder residue. These materials come from vehicle interiors, bumpers, and other components. The plastic fractions include both hard plastic fractions and softer varieties. Recycling these plastics requires advanced sorting techniques to separate clean plastic fractions from contaminated ones. High-quality plastic recyclates are essential for creating durable and sustainable products.

Rubber

Rubber originates from tires, seals, and other automotive parts. This fraction poses challenges due to its durability and resistance to degradation. Recycling rubber involves shredding it into smaller particles for reuse in products like playground surfaces or asphalt. Advanced separation methods help isolate rubber from other fractions, improving recycling efficiency.

Foam

Foam materials, such as those used in seats and insulation, contribute to the complexity of auto shredder residue. These lightweight materials are often difficult to separate. Recycling foam requires specialized processes to recover usable fractions. Recycled foam can be repurposed into products like carpet padding or insulation materials.

Glass

Glass in auto shredder residue comes from windows, mirrors, and light fixtures. This fraction is relatively easy to identify but challenging to recycle due to contamination. Clean glass fractions can be processed into new glass products or used in construction materials. Effective separation ensures that glass does not contaminate other recyclates.

Other Residual Materials

Auto shredder residue also contains miscellaneous materials. These fractions are often non-recyclable and require proper disposal. Reducing the volume of residual waste remains a priority for the recycling industry.

Challenges in Automotive Shredder Residues Recycling

Material Separation Complexity

Recycling automotive shredder residues presents significant challenges due to the complexity of material separation. These residues contain a mix of plastics, metals, rubber, foam, glass, and other materials. Each material requires a unique method for identification and extraction.

For example, plastics often need advanced sorting systems to distinguish between different types, while metals rely on magnetic or eddy current separation. The presence of small, intertwined particles further complicates the process.

Contamination Issues

Contamination remains a major obstacle in recycling automotive shredder residues. Residues often contain dirt, oil, and other impurities from end-of-life vehicles. These contaminants reduce the quality of recyclable materials, making them less suitable for reuse.

For instance, plastics mixed with oil or foam embedded with dirt require additional cleaning steps. This not only raises costs but also slows down the recycling process. Contamination can also lead to cross-contamination between materials, further reducing the efficiency of recovery efforts.

Economic Viability of Recycling Processes

The economic viability of recycling automotive shredder residues depends on several factors. High costs associated with advanced sorting technologies and contamination management often outweigh the value of recovered materials. Additionally, fluctuating market demand for recyclates impacts profitability. For example, low demand for recycled plastics or metals can make the process less attractive to recycling facilities.

Auto Shredder Residue Recycling Solutions

Magnetic Separators

Magnetic separators are essential for removing ferrous metals such as iron and steel from ASR. These metals can be easily captured by magnets and separated from the rest of the waste. The process involves running the material through a magnetic field where metals are attracted and removed, leaving behind plastics, glass, and other materials for further processing.

Eddy Current Separators

Eddy current separators are designed to recover non-ferrous metals like aluminum and copper. They work by generating a rotating magnetic field that induces electric currents in metal materials. These currents cause the non-ferrous metals to be repelled from the rest of the material stream, allowing them to be separated and collected.manufacturing.

Vibrating Screens

Vibrating screens are widely used to separate materials by size. These machines shake or vibrate to sift through ASR, allowing smaller particles like dust and sand to fall through mesh screens while larger materials, like plastics and rubber, remain on top. Vibrating screens help separate fine particles from larger, more valuable materials, ensuring a cleaner and more effective recycling process.

Trommel Screens

Trommel screens are rotating drums with perforated holes that sort materials based on size. As the drum rotates, the ASR moves inside, and smaller materials fall through the holes while larger materials stay in the drum. Trommel screens are excellent for separating coarser materials, such as rubber and glass, from the rest of the waste stream. This step helps improve the quality of the materials being recycled.

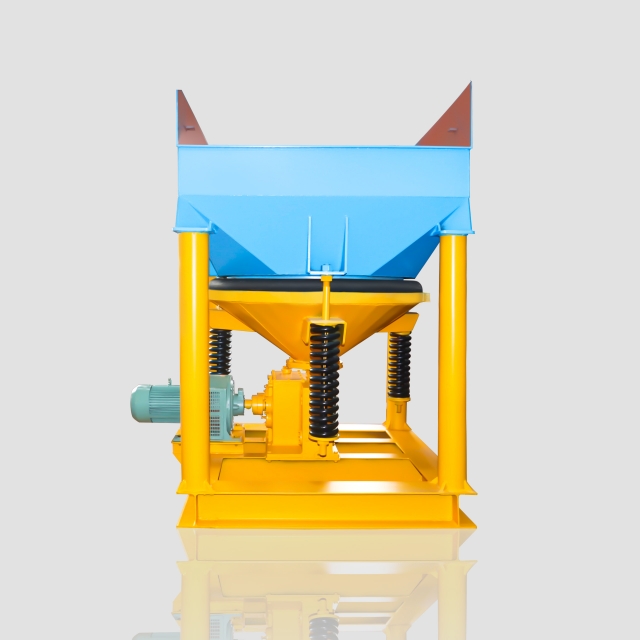

Gravity Sorting Machines

Gravity sorting machines use the force of gravity to separate materials based on their density. Heavier materials, like metals and glass, sink to the bottom, while lighter materials, such as plastics and foams, stay on top. Machines like shaking tables, air tables, and jigging machines are commonly used in gravity sorting. They are simple, energy-efficient, and environmentally friendly methods for sorting ASR.

Auto Shredder Residue Recycling Process

1. Shredding the Vehicles

- The vehicles are fed into a powerful shredder, which breaks them into smaller pieces, including metals, plastics, glass, and other materials.

2. Magnetic Separation (for Ferrous Metals)

- After shredding, ferrous metals (such as steel and iron) are separated using magnets. These magnetic separators can be overhead or integrated into conveyor systems to efficiently pull ferrous materials out.

3. Eddy Current Separation (for Non-Ferrous Metals)

- For non-ferrous metals, an eddy current separator is used. The eddy current creates an opposing magnetic field that pushes non-ferrous metals off the conveyor belt, while other materials continue.

4. Plastic and Glass Separation

- The remaining shredded materials, known as Auto Shredder Residue (ASR), which include plastics and glass, are sorted through various separation methods:

- Vibratory Screens: These screens use vibration to help sort materials based on size and density.

- Thommel Screens: Rotating drum screens that separate materials based on their size and movement.

- Gravity Separation: Materials are separated based on their weight, with heavier glass falling while lighter plastics are blown or separated.

5. Waste Disposal

- Any remaining non-recyclable materials that cannot be processed further are sent to a landfill or undergo additional treatment as necessary.

Conclusion

Recycling Auto Shredder Residue is essential for reducing environmental impact, yet it faces challenges like material separation and contamination. With continued technological advancements, the recycling process can be made more efficient, helping turn waste into reusable materials and promoting sustainability in the automotive industry.