Aluminium exists as one of the world’s top metallic materials because people use it extensively throughout beverage and aircraft manufacturing among countless other applications. Due to its diverse applications and weight-bearing capabilities together with its lightweight aspect aluminium stands critical for industries.

The main sustainability benefit of aluminium stems from its capability to be recycled repeatedly without quality reduction. The recyclability of aluminium allows multiple cycles with no reduction to quality thus making it a fundamental element to achieve circular economy success.

The essential need for aluminium metal recycling for sustainability and the recycling operations along with RUIJIE’s contribution to environmental improvements, will be explained throughout this piece.

The Aluminium Recycling Process

The first step in aluminium recycling starts with gathering various kinds of scraps that include cans from beverages along with construction materials and factory waste as well as industrial residues.

After collection the aluminum materials progress to a sorting operation that clears the metal from various materials and contaminants. Sorting effectiveness determines the final purity of recycled aluminum since it requires thorough and precise sorting procedures.

After sorting the aluminium pieces are made smaller through shredding which results in increased surface area to improve the efficiency of the melting process. The fragments are cleaned to get rid of paint and coatings and other unwanted substances before entering a high-efficiency furnace for the melting process. The melted aluminium receives form into molds through which it becomes either ingots or other product shapes suitable for new manufacturing processes.

The process of aluminium recycling stands out for sustainability because it needs just 5 percent of the energy needed to create fresh aluminium from raw bauxite mineral sources. Less energy usage during recycling processes makes aluminum recovery both economically sound and environmentally beneficial.

Benefits of Aluminium Metal Recycling

Multiple important factors demonstrate the necessity of aluminum recycling.

- Recycling aluminium reduces energy usage because it demands energy levels that equal only a small amount compared to initial production rates. The energy required for recycling produces fewer emissions which enables the reduction of fossil fuel dependence.

- Used aluminium products maintain their economic worth following their disposal. The reuse of aluminium waste presents industries with an economical choice over raw material purchases since it works well for both packaging solutions and automotive factory needs.

- The main extraction technique for bauxite creates major environmental challenges because it is the main source of aluminium. Aluminium recycling decreases the market demand for fresh materials thus protecting natural regions and minimizing environmental damage to land.

- Durable aluminium goods are disposed into landfills before recycling takes place. A properly established recycling system enables us to recover materials from waste thus making them available for reuse in manufacturing.

Environmental Impact Of Aluminium Recycling

The main environmental advantage of aluminium recycling emerges from its ability to minimize greenhouse gas emissions. The production process for aluminium from bauxite materials requires significant levels of energy consumption to generate substantial amounts of CO₂ emissions. The carbon emissions drop substantially through recycling which makes a crucial contribution to climate change battles.

Participating in aluminum recycling diminishes the weight of waste in landfills as well as prevents soil degradation during the mining and ore processing stages. This practice saves environmental water resources while simultaneously lowering airborne contaminant release.

The creation of aluminium through traditional methods requires chemical liquids which produce damaging red mud material. Recycling circumvents this issue entirely.

Aluminium recycling drives the global progress toward a circular economy since it allows resources to stay actively used while minimizing waste disposal. Continuous aluminium recycling allows this material to last longer before new raw material extraction becomes necessary.

RUIJIE and Sustainability in Aluminium Processing

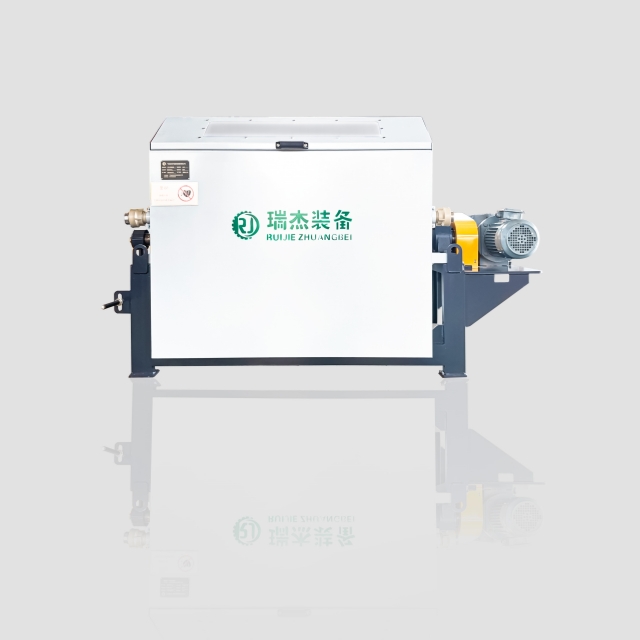

RUIJIE leads the development of industrial metal separation and sorting technology which drives worldwide advancement of aluminium recycling efforts. The company has developed advanced devices which efficiently extract high-value metals from industrial waste components including slag together with Auto Shredder Residue and Incinerator Bottom Ash.

RUIJIE operates beyond standard waste recovery methods that serve domestic and urban spaces because they build systems exclusively for industrial production sectors which demand advanced precision and performance.

Their recycling methods extract both aluminium and several precious metals from waste materials obtained after industrial production and consumer use to facilitate maximum yield and protect the environment.

RUIJIE demonstrates commitment to sustainability through their ongoing efforts in sensor-based sorting and eddy current separation technology development which enhances non-ferrous metal particularly aluminium extraction quality. The decrease of virgin material requirement and worldwide development of eco-friendly recycling structures result from this approach.

Frequently Asked Questions

- Why is aluminium considered a sustainable metal?

Aluminium is highly sustainable because it can be recycled indefinitely without losing its quality. The recycling process uses only about 5% of the energy required to produce primary aluminium, making it an energy-efficient and eco-friendly option that supports a circular economy. - How does aluminium recycling help reduce environmental impact?

Recycling aluminium significantly reduces greenhouse gas emissions, conserves natural resources by lowering the demand for bauxite mining, and minimizes landfill waste. It also eliminates harmful byproducts like red mud, which are common in primary aluminium production. - What types of industrial waste can aluminium be recovered from?

Aluminium can be recovered from a wide range of industrial waste sources, including slag, Auto Shredder Residue (ASR), and Incinerator Bottom Ash. Advanced equipment like RUIJIE’s sensor-based sorters and eddy current separators make this recovery process highly efficient and precise.

Conclusion

Knowledge about the vital role of aluminium metal recycling in sustainability creation will help establish a sustainable future that is cleaner and greener. The measurable advantages of aluminium recycling include both energy savings and waste decrease as well as emissions reduction and resource protection. The expanding market for aluminium demands sustainable lifecycle management because of its growing demand.

RUIJIE along with other companies stands at the forefront of developing innovative solutions to extract aluminium from industrial waste products. RUIJIE’s technological capabilities drive better performance in recycling operations therefore locking down key resources while minimizing ecological harm.

Investment in aluminium recycling and supporting technologies will bring our society closer to a sustainable circular economy system which maximizes material reuse while conserving ecosystems for future benefits.