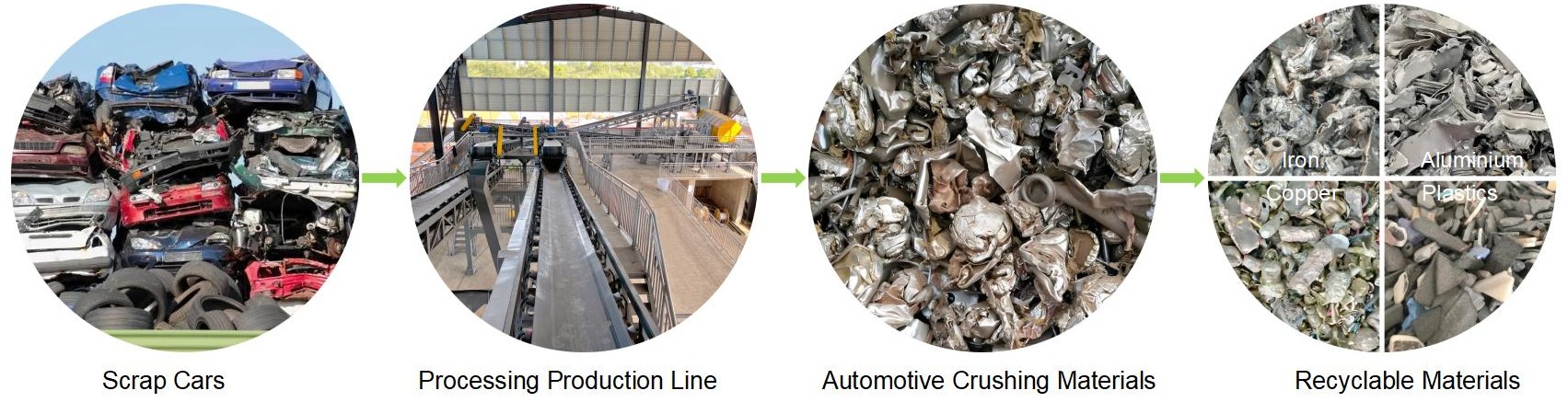

Automotive shredder Residue (ASR)

Recovery Solution

RUIJIE-Your Trusted ASR Recycling Equipment Manufacture

We focus on the research and development and production of solid waste separation machinery ASR, with more than 15 years of solid waste separation manufacturing and technical experience, in a leading position in the domestic peers.

We specializes in crushing end-of-life vehicles and sorting valuable magnetic metals to design a production line with a high recovery rate.In addition, we have independently developed magnetic separation machines and eddy current sorting machines, etc., with our induction sorting systems and combined sorting systems.

Pure metals and remnants can be selectively generated and formed as an excellent first stage before downstream processing, and can also be produced in a variety of configurations to optimally adapt to specific tasks and situations.

We Professional Magnetic Separation Equipment can effectively sort the scrapped cars, and automatically separate the copper, aluminum, stainless steel and iron in them to realize the recycling of garbage.

If you would like to know more about ASR processing recycling systems and related equipment, please do not hesitate to contact us.

Global Trends in end-of-life Vehicle Recycling

The disposal and recycling of end-of-life vehicles has become an increasingly urgent issue, posing not only a challenge to environmental protection, but also resource reuse and sustainable development.

In recent years, the global end-of-life vehicle recycling industry has been expanding. According to relevant data, the recycling of end-of-life vehicles shows a steady growth trend.

With the continuous development of digital and intelligent technologies, the end-of-life vehicle recycling industry is expected to achieve more efficient and accurate recycling and disposal. For example, real-time monitoring and tracking of end-of-life vehicles can be achieved through Internet of Things technology, and intelligent dismantling and classification of end-of-life cars can be carried out through artificial intelligence technology. The application of these technologies will help improve recycling efficiency, reduce costs, and reduce environmental pollution.

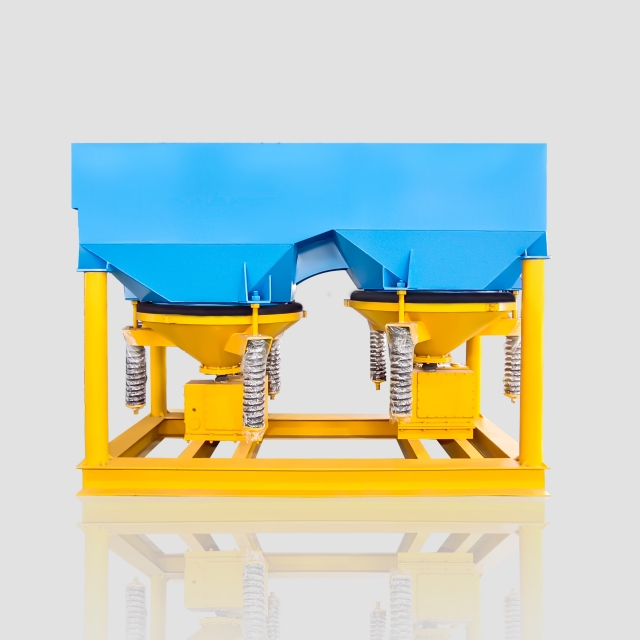

Our ASR Advanced Sorting Solutions Provide Superior Removal Results

We offer high-sensitivity sensor sorters that effectively separate automotive shredding residue (ASR) with optimal performance. The quality of our Eddy Current Separator and Magnetic Separation Machine has been recognized by customers worldwide.The sorting efficiency of the eddy current separator has been significantly improved compared with the traditional sorting method, and its sorting efficiency is about 98% according to the different materials.

It is a modern special equipment in the field of solid waste recycling. The purpose of its development is to better recover metals from solid waste and to tap the potential metal resources in domestic waste and industrial waste as much as possible.

How to Dispose of Car Shredding Residue?

Automotive shredding residue treatment focuses on recycling all usable materials, reducing their volume to reduce the use of landfill space, and recovering energy from plastics and other components.

Since approximately 40-50% of automotive residue is hydrocarbon materials (e.g. plastic, fiber, wood, paper, tar, and rubber, etc.), the amount that needs to be disposed of can be significantly reduced by:

1.Use a fine crusher to further crush these materials.

2.Valuable metals are further sorted through electromagnetic and eddy current methods.

3.Use equipment such as sorters and vibrating screens to separate combustible components such as fabrics, plastics and rubber from residues.

4.The remaining glass can be separated from high-purity glass by eddy current separator, glass color sorter and magnetic separator.

5.The remaining dirt and other components are sent to the landfill for landfill.

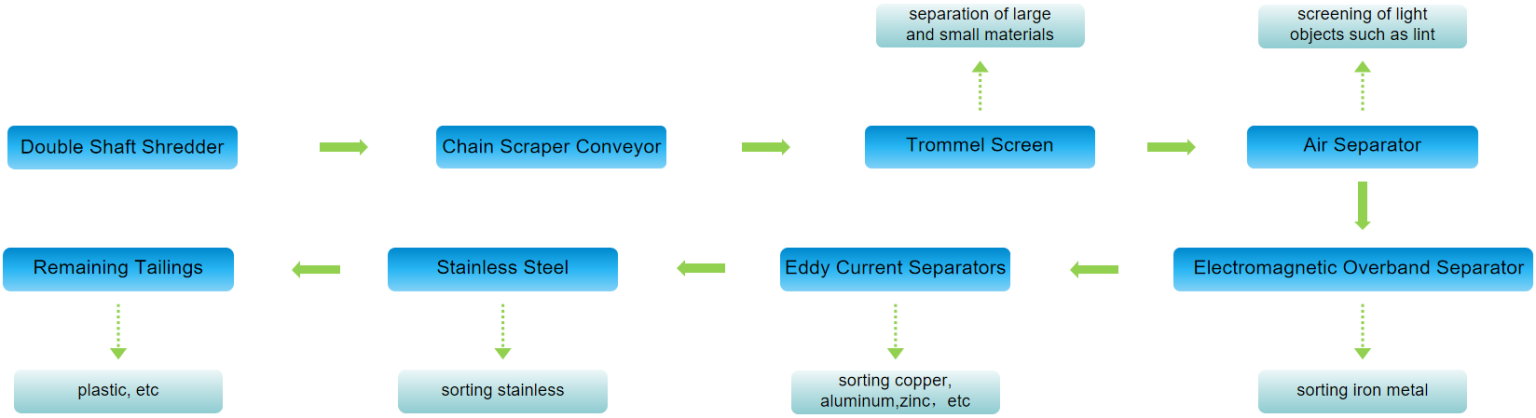

The Process of Sorting

The following sorting and recycling line process is for reference only, in addition, we can customize the production line and magnetic sorting machine according to the different needs of customers.

Solid Waste Shredder→ Chain Scraper Conveyor → Trommel Screen (screening out materials of inconsistent size), → Air Separator (screening of light floating objects such as lint), → Trommel Screen (separation of large and small materials), → Electromagnetic Overband Magnetic Separator (sorting iron metal), eddy current separators (Sorting copper, aluminum, zinc and other metals), → Stainless Steel Separators (sorting stainless steel) → Remaining Tailings.

Production Line 3D Drawing

The following drawings are for reference only, in addition, we can customize production lines and magnetic separation machines according to different needs of customers

The Process of Sorting

These are just routine recycling options, and ultimately they are customized according to the customer’s daily processing capacity and other sorting requirements.

If you would like to know more about recycling options, please contact us.