Inspiring Liuyang IBA Wet Sorting Project Successfully Launched and Operational

The Incinerator Bottom Ash(IBA) wet sorting project plant of our Liuyang client is located in Liuyang city, Hunan province, with 800 tons processing capacity per day. To promote resource recovery and contribute to environmental sustainability, achieve the goal of maximizing economic benefits. The Liuyang client adopted our Ruijie professional Incinerator Bottom Ash(IBA) wet sorting solution based on their daily processing capacity, plant area, production efficiency, and budget.

What’s the importance of IBA Wet Sorting Project ?

Incinerator Bottom Ash (IBA) is the residual material left after waste incineration. Traditionally, IBA has been considered a waste product, but with innovative solution, advanced slag equipment machine for sorting, it can now be transformed into a valuable resource. Therefore, IBA wet sorting project plays a critical role in incinerator bottom Ash and modern waste management by:

- Recovering Valuable Materials: separate metals such as iron, aluminum, copper, and non-metallic materials like glass and aggregates from Incinerator Bottom Ash.

- Reducing Landfill Waste: Minimizing the amount of residual waste that ends up in landfills.

- Protecting the Environment: Preventing the release of harmful substances into the soil and water.

- Promoting Circular Economy: Enabling the reuse of recovered materials in various industries.

How Does the IBA Wet Sorting Production Line Work?

According to Liuyang clients needs, we provide a comprehensive project service, from the plant design, slag equipment customization, to machine installation and commissioning, ensure the whole production line operate stably. The complete production line includes our six series of core equipment: central control equipment, magnetic separation equipment, gravity sorting gravity equipment, screening equipment, conveying equipment, and crushing equipment.

Every slag equipment play a crucial role in the separation and recycle of valuable resources, there are parts of them work in the wet sorting production line:

- Trommel Screen: Classify different particle sizes materials, grade and separate large and small lumps when materials are conveying to.

- Permanent Magnetic Separator:Screen the fine iron on the table concentrator, effectively automatically separate the iron materials from other materials.

- Electromagnetic Over-band Separator: Absorb large iron pieces, effectively separate the iron materials in the conveyor belt from other materials.

- Jig concentrator: Separate weakly magnetic metals like silver, copper, and tungsten by using specific gravity differences of the materials.

- Hammer Crusher: The magnetic metal can evenly crushed by the Iron hammer crusher, while nonmagnetic metal is crushed by the stone hammer crusher.

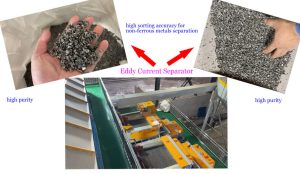

- Eddy current separator: Separate aluminum and other non-ferrous metals from 3–12 mm particles.

- Spiral Sand Washing Machine: be used for washing, grading and impurity removal of the sand

- Dewatering Screen: be used for dehydration and desliming the sand.

Benefits of the IBA Wet Sorting Project

The project of the IBA wet sorting production line help our client enhance resource recovery rates, lower processing costs, achieve zero wastewater discharge, minimize environmental impact, and generates additional revenue from recycled materials. For example, the sorted iron/aluminum metal can be sold or recycled, the treated sand can be used roadbed material, making environmentally friendly bricks, or for landfill.

Future Trends in IBA Wet Sorting

- The future of IBA wet sorting lies in continuous innovation and technological advancements. Key trends include:

- Automation and AI: Enhancing sorting efficiency through automated systems and artificial intelligence.

- Advanced Separation Technologies: Developing more efficient magnetic and gravity separators.

- Sustainable Practices: Focusing on energy-efficient and environmentally friendly solutions.

Conclusion

The successful commissioning of the Liuyang IBA wet sorting project marks another milestone in our technical capabilities and service excellence in the field of slag treatment. We will continue to prioritize client needs, drive technological innovation,keep pace with social development, and contribute to global environmental protection and resource recycling.