Non-ferrous metals play a crucial role in various industries due to their lightweight, durable, and corrosion-resistant properties. Metals like aluminum and copper are widely used in sectors such as automotive and electronics.

As the demand for non-ferrous metals continues to grow, their separation has become increasingly important. This process not only helps recover valuable metals but also supports environmental protection and sustainable development.

In this article, we will explore the advantages of non ferrous metal separation and the effective technologies currently in use.

Understanding Non-Ferrous Metals

What are non-ferrous metals?

Non-ferrous metals are metals that do not contain iron, setting them apart from ferrous metals. These metals are non-magnetic and highly resistant to corrosion, making them indispensable across numerous industries.

Non-ferrous metals are known for being lightweight, durable, and exceptional conductors of electricity and heat. Their adaptability allows them to be utilized in a wide range of applications, from construction to advanced electronics.

Because they lack iron, non-ferrous metals do not rust, even in moist or humid conditions. This makes them particularly suitable for outdoor use and environments with high humidity.

Examples of non-ferrous metals and their uses

A variety of non-ferrous metals play vital roles in modern industrial applications.

- Aluminum, for example, is extensively used in packaging, transportation, and construction due to its lightweight and corrosion-resistant characteristics.

- Copper, another widely used non-ferrous metal, is essential for electrical wiring and plumbing because of its superior conductivity.

- Zinc is commonly employed for galvanizing steel to prevent rust, while lead is used in batteries and radiation shielding.

- Precious non-ferrous metals like gold and silver are integral to jewelry, electronics, and currency.

- Nickel, another important non-ferrous metal, is crucial in the production of stainless steel and rechargeable batteries.

Each of these non-ferrous metals contributes significantly to the efficiency and sustainability of countless products.

Benefits of Non Ferrous Metal Separation

Environmental benefits, including resource conservation

Non ferrous metal separation plays a vital role in protecting the environment. Recycling non ferrous materials reduces the need for mining raw ores, which helps conserve natural resources. This process also minimizes energy consumption since recycling metals like aluminum requires significantly less energy than producing them from raw materials. Lower energy use leads to reduced greenhouse gas emissions, contributing to a cleaner atmosphere.

By using technologies like the eddy current separator, recycling facilities can recover valuable metals that might otherwise end up in landfills. This reduces waste and prevents harmful substances from contaminating soil and water. Non-ferrous recycling supports a circular economy, where materials are reused instead of discarded, promoting long-term sustainability.

Economic benefits, such as cost savings and revenue generation

Non ferrous metal separation offers substantial economic advantages. Recycling facilities save money by recovering valuable metals instead of purchasing new raw materials. For example, separating aluminum and copper through an eddy current separator allows businesses to reuse these metals in manufacturing, cutting costs.

Additionally, selling recovered non-ferrous metals generates revenue. Metals like copper and aluminum have high market value, making them profitable for recycling companies. Efficient metal separation also reduces waste disposal costs, further improving financial outcomes. These economic benefits make non-ferrous recycling a smart investment for businesses.

Operational benefits, like improved recycling efficiency

Advanced separation technologies enhance the efficiency of recycling operations. Tools like the eddy current separator enable facilities to process large volumes of mixed materials quickly and accurately. This reduces the time and labor required for manual sorting, allowing facilities to handle more waste with fewer resources.

High-quality separation ensures that recovered metals are free from contamination, improving their usability in manufacturing. Automated systems also reduce human error, increasing the reliability of the recycling process. By streamlining operations, non-ferrous metal separation helps recycling facilities meet growing demand while maintaining high standards of quality.

How Eddy Current Separators Work?

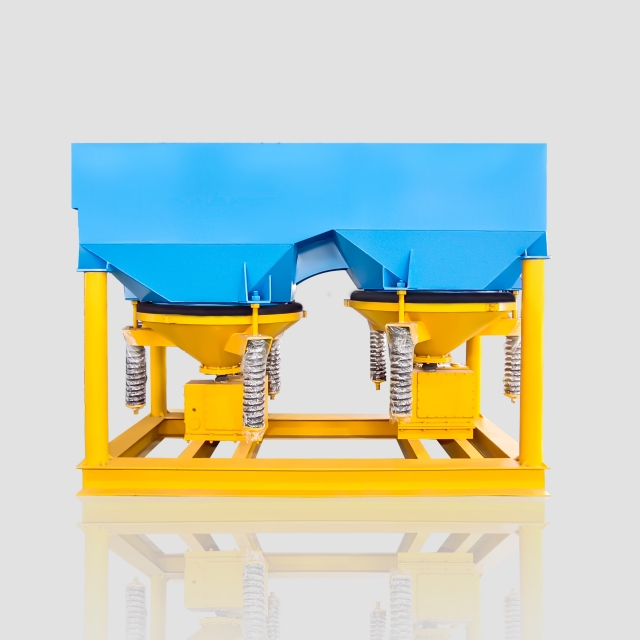

An eddy current separator is a critical tool in the recycling industry. It uses a magnetic rotor to create a powerful magnetic field. When non-ferrous metals pass through this field, they experience a force that repels them away from other materials. This process relies on the principle of electromagnetic induction. The separator generates eddy currents within the non-ferrous metals, causing them to be ejected from the waste stream.

The design of an eddy current separator includes a conveyor belt system. The belt carries mixed materials toward the magnetic rotor. As the rotor spins at high speed, it creates the necessary magnetic field. Non-ferrous metals, such as aluminum and copper, are separated from non-metallic materials like plastic or glass. This method ensures effective separation and improves recycling efficiency.

Applications of Eddy Current Separators

The automotive sector is one of the largest users of this technology. Vehicles contain significant amounts of aluminum, copper, and other non-ferrous materials. Recycling these metals reduces the need for raw material extraction and supports sustainable manufacturing. For instance, aluminum from car frames and copper from wiring can be recovered using an eddy current separator, ensuring minimal waste.

The electronics industry also benefits greatly from non-ferrous metal separation. Electronic devices, such as smartphones, laptops, and circuit boards, contain valuable metals like gold, silver, and copper. Recycling facilities use advanced technologies, including the eddy current separator, to extract these materials efficiently. This process not only conserves resources but also prevents hazardous e-waste from polluting the environment.

Conclusion

Non-ferrous metal separation offers significant environmental, economic, and operational benefits. By efficiently recovering valuable metals, this process reduces the need for raw material extraction, conserving natural resources and minimizing energy consumption. The use of eddy current separators ensures higher efficiency and better quality in the recycling process. As industries continue to evolve, the role of non-ferrous metal separation in fostering sustainability and supporting a circular economy will only become more essential.