Trommel screens play a vital role in industries like recycling, mining, and quarrying. These machines separate materials by size, ensuring efficient processing of recyclable materials. Their design directly impacts performance, durability, and adaptability. In this article, we will explore the key features of trommel screen design, as these determine the trommel screening machine’s performance in various applications.

Purpose and Functionality of Trommel Screens

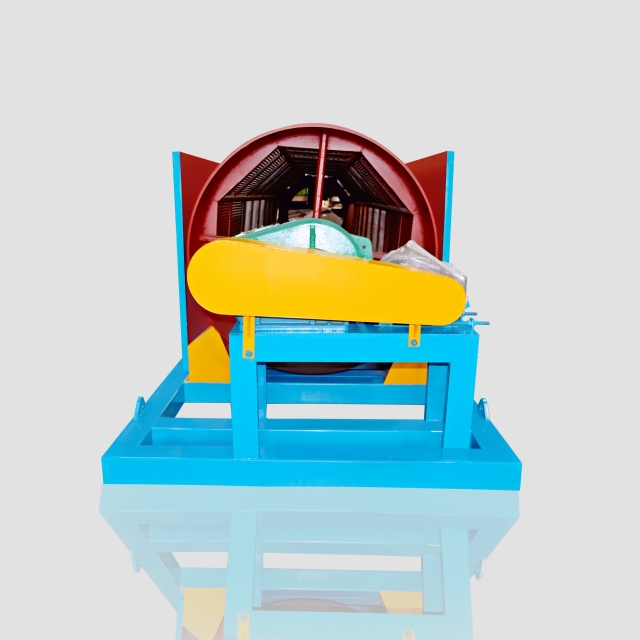

A trommel screening machine serves as a critical tool for material separation in various industries, and the trommel screen design is essential for optimizing this process. Its primary function is to sort materials based on size using a rotating cylindrical drum. The drum, inclined at an angle, allows smaller particles to pass through its mesh openings while larger particles exit at the end. This process ensures efficient separation, making trommel screens indispensable in industries like waste management, mining, and construction.

Key Factors to Consider in Trommel Screen Design

There are several factors to consider for an effective trommel screen design, helping achieve optimal performance.

Factors Affecting Production Rate

The production rate of a trommel screening machine depends heavily on its drum diameter, rotational speed, and slope.

- A larger drum diameter increases the surface area available for material separation, enhancing material throughput. However, oversized drums may reduce efficiency if not paired with the correct speed and slope.

- Rotational speed determines how quickly materials move through the drum. Faster speeds improve throughput but may compromise the screening process by reducing retention time. Conversely, slower speeds allow for better separation but can lower production rates.

- The slope of the drum also plays a critical role. A steeper slope accelerates material movement, increasing throughput. However, excessive steepness may lead to incomplete separation.

Engineers must carefully balance these factors to optimize the trommel’s performance for specific applications.

Factors Affecting Screening Efficiency

Screening efficiency relies on several key factors, including retention time, screen area, and hole shape.

- Retention time refers to how long materials remain inside the drum. Longer retention times improve separation by allowing materials to interact more thoroughly with the screen. However, excessive retention can reduce material throughput, creating a bottleneck in the process.

- The screen area directly impacts the trommel’s ability to separate materials. A larger screen area provides more opportunities for particles to pass through, enhancing efficiency.

- Engineers must also consider the shape and size of the screen holes. Circular holes are ideal for uniform materials, while slotted or square holes work better for irregular particles.

Matching Trommel Capability to Material Requirements

Matching a trommel’s design to the material it processes is essential for achieving optimal performance. Different materials have unique characteristics, which influence the choice of screen type.

- Material weight

The weight of material plays a critical role in the performance of trommel screens. Heavier materials exert more pressure on the drum screens, influencing the durability and efficiency of the equipment. A mismatch between the material’s weight and the screen can lead to premature wear or operational inefficiencies. This factor should be considered when selecting the appropriate screens to ensure long-term performance. - Material Size

The size distribution of particles, directly affects the efficiency of a trommel screen. Smaller particles can pass through the screen quickly, while larger ones may need more retention time. Customization of screens might be required for specific needs to ensure maximum throughput and minimal clogging. - Moisture Content

High moisture content in materials presents significant challenges for trommel operation. Wet or sticky materials tend to clump together, clogging the screen and reducing efficiency. This issue is common in waste management, where organic waste often contains high moisture levels. To address this, trommel designs may include features like cleaning brushes or self-cleaning screens. Understanding the moisture content of the material is essential for selecting the right screens and ensuring smooth operation.

How to Design a Trommel Screen for Optimal Performance

Trommel screen design requires the following features:

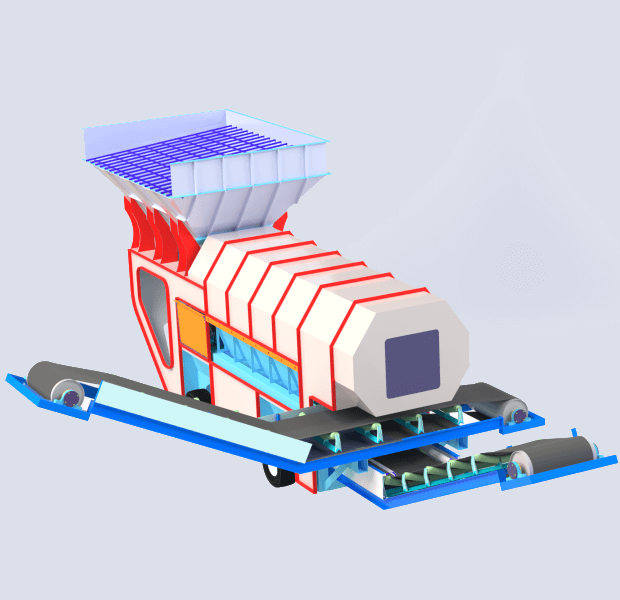

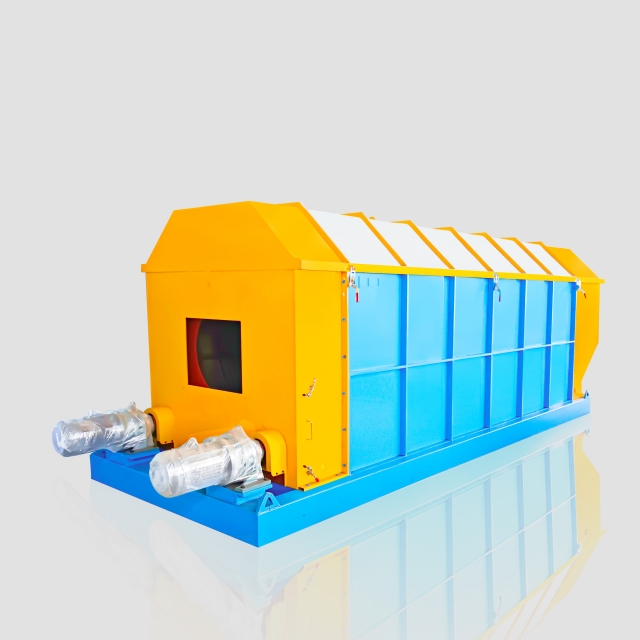

Types of drums

The design of the trommel drum significantly influences its performance and suitability for specific applications. Two primary types of drums exist: skeletal and solid. Skeletal drums feature an open framework, making them ideal for applications where lightweight construction and easy maintenance are priorities. These drums often find use in industries like recycling, where materials such as waste or compost require efficient separation.

Solid drums, on the other hand, consist of a fully enclosed structure. These drums are better suited for heavy-duty applications, such as mining, where durability and the ability to handle abrasive materials are critical. The choice between skeletal and solid drums depends on the material being processed and the operational demands of the trommel.

Lifter bars

Lifter bars enhance the efficiency of trommel screens by improving material movement and agitation. They are placed inside the drum, agitate the material to promote better separation. This feature is particularly useful when processing sticky or wet materials, as they reduce the risk of clogging and improve overall efficiency.

Screen Type

The type of screen used in a trommel plays a crucial role in its performance. Perforated plate screens, made from solid metal sheets with punched holes, offer durability and resistance to wear. These screens are ideal for heavy-duty applications, such as mining, where abrasive materials are common. Mesh screens, constructed from woven wire, provide greater flexibility and are better suited for lighter materials like compost or fine aggregates.

The size and shape of the holes in the screen directly affect material separation. Larger holes allow for faster throughput but may compromise precision. Smaller holes improve accuracy but can reduce processing speed. The shape of the holes, whether circular, square, or slotted, also impacts the separation process. Engineers must carefully select the screen size and hole shape to match the material’s granulometry and achieve optimal performance.

Drive Systems

The drive system determines how the trommel drum rotates, influencing its reliability and efficiency. Friction drives use rollers to rotate the drum and are suitable for lightweight applications. Chain drives, which rely on a chain and sprocket mechanism, provide greater torque and are ideal for medium-duty operations. Gear drives, offering precise control and high durability, are preferred for heavy-duty applications like mining. Selecting the appropriate drive system ensures the trommel operates smoothly and meets the demands of the material being processed.

Dust Suppression Systems

Dust suppression systems address environmental and workplace safety concerns. Trommel operations, especially in industries like mining and construction, can generate significant dust. Dust suppression systems, including water sprays, minimize airborne particles, protecting workers and nearby communities. These features ensure compliance with environmental regulations while maintaining operational efficiency.

Custom Designs of Trommel Screens at RUIJIE

Custom design of trommel screens is crucial for optimizing performance and efficiency in material processing. Some screening machines may not meet the specific needs of different industries, as materials vary in size, moisture content, and abrasiveness.

A custom trommel screen allows for adjustments in drum speed, perforation size, and angle to handle specific materials more effectively. Additionally, custom designs can include durable components to withstand harsh conditions and reduce maintenance needs.

Custom trommel screen design ensures better separation, increased throughput, and longer operational life, ultimately boosting productivity.