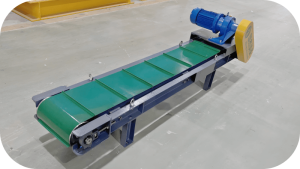

Permanent Magnetic Separator: Efficient and Stable Iron Removal Solution

In today’s highly competitive mining and renewable resource recycling fields, efficient, durable and reliable equipment is one of the key factors for the success of enterprises. In order to improve production efficiency and product quality, an efficient and stable iron removal equipment is essential. Today, we are honored to introduce you to an innovative iron removal equipment -the permanent magnetic separator. With its excellent design and high-quality materials, this equipment provides users with excellent iron removal effects and has become the first choice of many companies.

In today’s fiercely competitive mining and renewable resource recycling industry, efficient, durable, and reliable equipment is one of the key factors for companies to achieve success. In order to improve production efficiency and product quality, an efficient and stable iron removal equipment is essential. Today, we are honored to introduce to you an innovative iron removal device – the shaker hanging iron remover. This device, with its excellent design and high-quality materials, provides users with outstanding iron removal effects and has become the first choice for many enterprises.

The core components of the permanent magnetic separator

As a key part of iron removal equipment, the permanent magnetic separator plays an irreplaceable role in separating magnetic and non-magnetic materials. This permanent magnetic separator, carefully crafted by Ruijie Equipment, is mainly composed of core components such as the active roller, the driven roller, the bearing seat, the main beam bracket,the magnetic group, the motor and the belt. Each component has undergone strict material selection and exquisite craftsmanship to ensure that the overall performance of the equipment reaches the top level in the industry.

Active and passive rollers: sturdy and durable, anti magnetic and anti rust

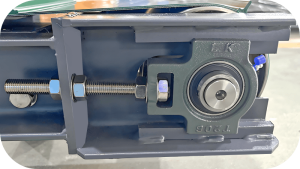

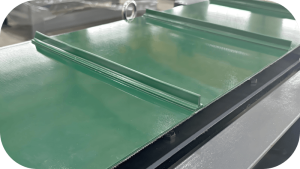

Firstly, let’s take a look at one of the core components of the permanent magnetic separator – the active roller and the passive roller. Both rollers are crafted from 304 stainless steel with a thickness of 5 mm. Known for its excellent corrosion resistance and mechanical strength, 304 stainless steel is an ideal material in numerous industrial applications. The selection of 304 stainless steel not only ensures the durability of the drum, but more importantly, its non deformable characteristics enable the drum to maintain stable performance even after long-term operation.

In addition, 304 stainless steel also has the characteristic of not being easily magnetic, which is particularly important for iron removers. The 304 stainless steel drum used in the permanent magnetic separator effectively reduces the adsorption of iron materials, improves iron removal efficiency, and reduces maintenance costs.

What is even more pleasing is that the rust prevention performance of 304 stainless steel is also extremely excellent. Its excellent anti rust ability ensures that the drum can still maintain good working condition in humid and harsh working environments, avoiding the adverse effects of rust on equipment performance, significantly extending the service life of equipment, reducing equipment replacement costs, and bringing long-term economic benefits to the enterprise.

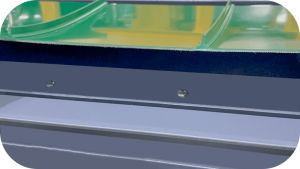

Main beam bracket: 201 stainless steel, stable and durable

The main beam bracket of the permanent magnetic separator is also an important supporting part of the entire equipment, made of 201 stainless steel material. Similar to 304 stainless steel, 201 stainless steel also has the excellent characteristic of not easily conducting magnetism, which ensures that the main beam will not interfere with the magnetic field during equipment operation, ensuring effective adsorption and separation of magnetic materials by the electromagnetic group.

Moreover, the rust prevention performance of 201 stainless steel effectively resists the erosion of the main beam by factors such as water vapor and chemicals in the working environment, preventing the occurrence of rust. Even under long-term high load operation, the main beam can still maintain a stable structure and reliable performance, providing strong support for the stable operation of the entire equipment. Its durability not only reduces the frequency of equipment maintenance and replacement caused by main beam damage, but also reduces the risk of production interruption caused by equipment failure, further enhancing the production continuity and stability of the enterprise, and strengthening its competitiveness in the market.

In the permanent magnetic separator, the 201 stainless steel main beam bracket not only provides stable support, but also ensures the stability and durability of the entire equipment. Like the drum, the main beam bracket is also not easily magnetized, avoiding the adsorption of iron on the bracket and maintaining the cleanliness and efficient operation of the equipment. At the same time, the rust prevention performance of 201 stainless steel also provides long-term protection for the main beam bracket, extending the service life of the equipment.

Magnetic group: precise iron removal, significant effect

The magnetic group is one of the core components of the iron remover, and its performance directly affects the iron removal effect. The magnetic group has been optimized and designed to generate a high-intensity and stable magnetic field, achieving efficient adsorption and precise separation of magnetic materials, effectively improving the recovery rate and concentrate grade of mineral processing.

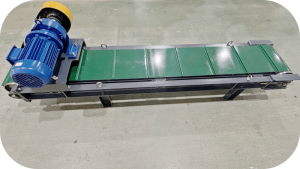

Motor and belt: Strong power, smooth transmission

In addition to the drum and main beam bracket, the motor and belt of the permanent magnetic separator are also important components. As the power source of the equipment, the performance of the motor directly affects the operating efficiency and stability of the entire equipment. The permanent magnetic separator adopts an efficient and energy-saving motor, which not only provides strong power output, but also ensures the low noise and low energy consumption operation of the equipment.

The belt is responsible for transmitting the power of the motor to the drum, achieving the rotational motion of the drum. The permanent magnetic separator uses high-quality belt materials to ensure smooth and reliable transmission. Even under long-term high-intensity operation, the belt can maintain stable performance, providing users with an excellent user experience.

Conclusion

With its excellent design and high-quality materials, the permanent magnetic separator provides users with an efficient and stable iron removal solution. Whether it is the durability, anti-magnetic and anti-rust of the drum, the solid support of the main beam bracket, the strong power of the motor, or the precise iron removal of the magnetic group, every detail reflects the excellent performance and excellence of this equipment.

For companies looking for efficient iron removal equipment, a permanent magnetic separator is undoubtedly an ideal choice. It can not only improve production efficiency, but also reduce maintenance costs, bringing greater economic benefits to your business. If you are interested in our products, please feel free to contact us at any time. We will provide you with more detailed product information and professional technical support. Let’s join hands and create a better future together!